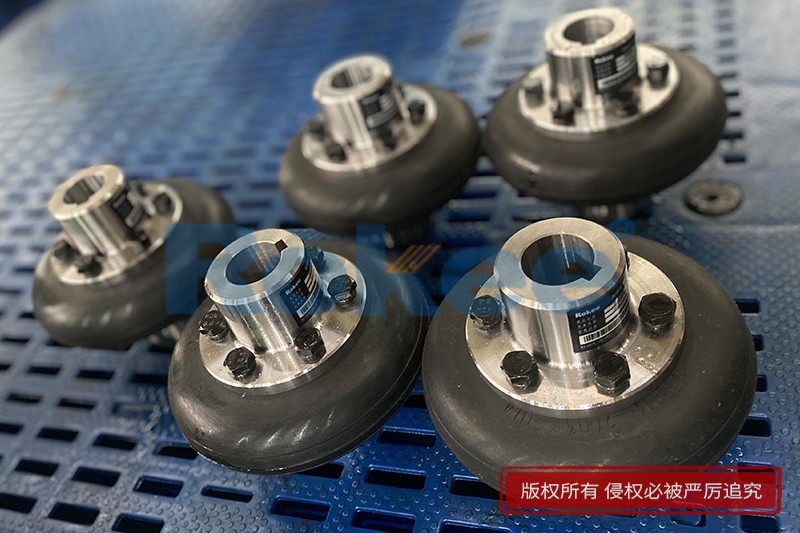

Tire Couplings

Rokee is Tire Couplings Manufacturer, Customizable according to the tire couplings drawings provided by the customer, Support Export.

The Tire Coupling adopts tyre body-shaped rubber elements, which are connected with two semi-couplings through bolts to realize torque transmission and displacement compensation. Tire Coupling has high elastic performance, small torsional rigidity, strong damping capacity, large axial compensation capacity, and good damping performance.

UL Elastic Tyre Coupling

UL Elastic Tyre Coupling adopts the structure of vulcanizing and bonding the tyre body with the metal connecting plate with threaded holes, which is then directly connected to the two semi-couplings by bolts for torque transmission and other displacement compensation.View MoreLLA Elastic Tyre Coupling

The LLA Elastic Tyre Coupling uses two semi-couplings to connect both sides of the elastic tyre body through internal pressing plates and bolts, making it easy to replace the elastic tyre body.View MoreLLB Elastic Tyre Coupling

The LLB Elastic Tyre Coupling is formed by fixing two halves of the coupling and the tire body together through bolts. The shaft hole type can be Y type, J1 type, and Z1 type. It has good shock absorption and excellent inter axle offset compensation performanceView More

In the complex ecosystem of mechanical transmission systems, couplings serve as the critical link that bridges rotating shafts, ensuring the smooth transfer of torque while accommodating inevitable misalignments and mitigating operational shocks. Among the diverse range of coupling types, tire couplings stand out for their unique combination of flexibility, damping capacity, and ease of use. Characterized by an elastomeric tire-like element that connects two metal hubs, tire couplings have become indispensable components in numerous industrial sectors, from heavy metallurgy and mining to general manufacturing and power generation.

1. Definition and Core Components of Tire Couplings

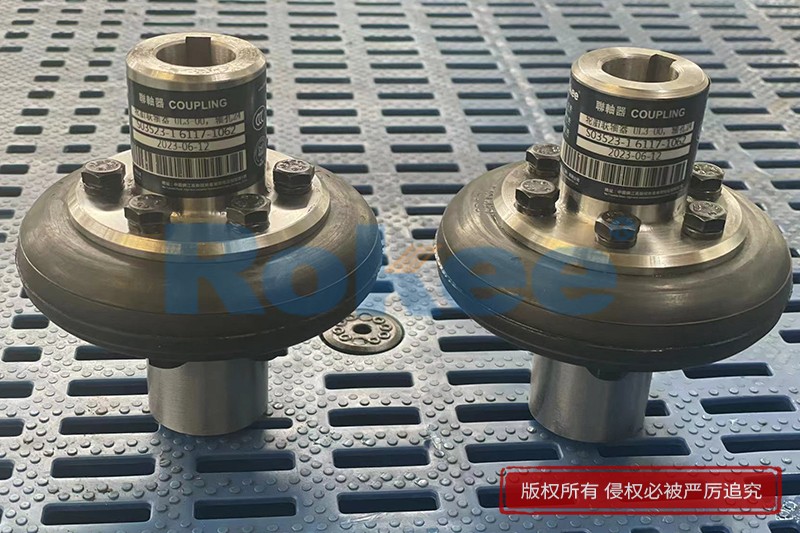

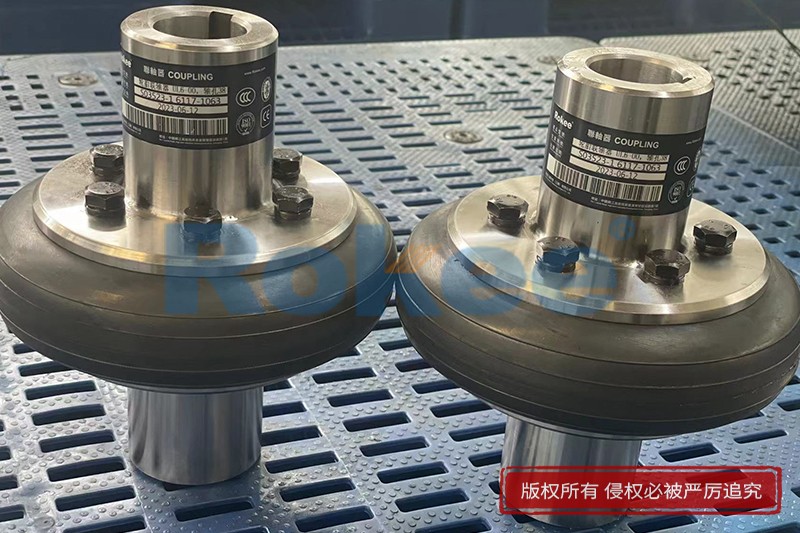

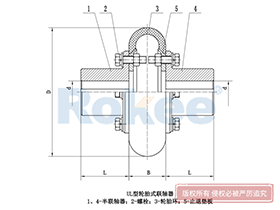

A tire coupling is a type of flexible coupling designed to transmit torque between two coaxial shafts while compensating for axial, radial, and angular misalignments. Its core design revolves around three essential components: two metal hubs (also known as semi-couplings), an elastomeric tire body, and connecting fasteners (typically high-strength bolts). Each component plays a vital role in ensuring the coupling's overall performance and durability.

The metal hubs are precision-machined components that attach to the driving and driven shafts. Commonly fabricated from high-strength materials such as carbon steel (e.g., C45), alloy steel, or cast iron, these hubs are engineered to withstand the torsional forces generated during torque transmission. The hub design often includes shaft holes with standardized configurations (e.g., Y-type, J1-type, Z1-type) to facilitate compatibility with different shaft sizes and connection methods, ensuring a secure fit that minimizes slippage during operation . Some hub designs may also feature welded nuts at bolt hole locations to enhance connection stability and simplify assembly.

The elastomeric tire body is the defining element of tire couplings, responsible for their flexibility, damping capabilities, and misalignment compensation. Typically made from composite rubber materials—such as natural rubber (NR) blended with synthetic rubbers like nitrile butadiene rubber (NBR) or styrene-butadiene rubber (SBR)—the tire body is often reinforced with embedded nylon threads, nylon cloth, or steel cords to improve tensile strength, fatigue resistance, and service life . The manufacturing process of the tire body involves vulcanization, a heat treatment process that bonds the elastomeric material to a steel frame (if present) or directly to the hub interfaces, creating a robust and integrated structure. This vulcanization process ensures that the tire body maintains its elastic properties even under repeated torsional deformation .

High-strength bolts serve as the connecting medium between the metal hubs and the tire body. During assembly, these bolts are tightened to create a frictional force between the tire body and the hub flanges, which is the primary mechanism for torque transmission. Unlike some other coupling types that rely on keyway connections, the frictional transmission method of tire couplings reduces stress concentrations on the shafts, minimizing the risk of shaft damage .

2. Working Principle of Tire Couplings

The operational principle of tire couplings is rooted in the elastic deformation of the elastomeric tire body, which enables both torque transmission and misalignment compensation. When the driving shaft rotates, torque is first transferred to the corresponding metal hub. This torque is then transmitted to the tire body through the frictional force between the hub flange and the tire surface. The tire body undergoes torsional shear deformation as it absorbs the torque, converting the rotational force into elastic potential energy. This potential energy is subsequently released to the driven hub, causing it to rotate in synchronization with the driving shaft .

A key aspect of this working principle is the ability of the tire body to accommodate various types of shaft misalignment. Axial misalignment (parallel displacement along the shaft axis) is compensated by the axial stretching or compression of the tire body. Radial misalignment (offset perpendicular to the shaft axis) is addressed through the lateral deformation of the elastomeric material. Angular misalignment (tilt between the two shafts) is resolved by the asymmetric torsional deformation of the tire body. Tests have shown that high-quality tire couplings can typically compensate for axial displacements of up to 5mm, angular misalignments of 1.5° to 3°, and radial misalignments within a certain range, depending on the specific model .

Another critical function of the tire body's elastic deformation is vibration damping. During machinery operation, especially in applications with frequent start-ups, stops, or variable loads, shock loads and vibrations are generated. The elastomeric material of the tire body absorbs these vibrations by converting the kinetic energy of vibration into heat, which is then dissipated into the surrounding environment. This damping effect reduces the transmission of vibrations to other components of the mechanical system, such as motors, reducers, and bearings, significantly extending their service life. It is estimated that high-performance tire couplings can absorb up to 30% of impact energy, effectively mitigating the damaging effects of sudden load changes .

3. Classification of Tire Couplings

Tire couplings can be classified into several types based on their structural configurations, each optimized for specific application scenarios. The most common classification criteria include the shape of the tire body, the connection method between the tire body and the hubs, and the integration of additional functions. The primary types are outlined below:

3.1 Convex and Concave Tire Couplings

This is the most basic classification based on the cross-sectional shape of the tire body. Convex tire couplings feature a tire body with a protruding cross-section, while concave tire couplings have a recessed cross-section. Convex tire couplings are further subdivided into three subtypes: skeleton-integrated, skeletonless-integrated, and radially slit . Skeleton-integrated convex couplings include a steel frame embedded within the tire body, providing enhanced structural rigidity and load-bearing capacity. Skeletonless-integrated types rely solely on the reinforced elastomeric material for strength, offering greater flexibility and misalignment compensation. Radially slit convex couplings have slits along the radial direction of the tire body, which improves their angular misalignment compensation capability and reduces the internal stress generated during deformation.

3.2 UL Series Tire Couplings

UL series tire couplings are a widely used type of highly elastic coupling, characterized by a vulcanized connection between the tire body and metal connecting plates with threaded holes. These connecting plates are directly bolted to the two semi-couplings, forming a compact and reliable structure. UL series couplings are known for their excellent shock absorption and damping performance, making them suitable for harsh working conditions with high humidity, dust, and frequent impact vibrations. They operate stably within a temperature range of -20℃ to 80℃ and can transmit torques ranging from 10N·m to 20000N·m, covering a wide range of power transmission requirements .

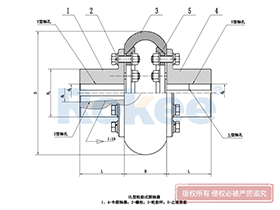

3.3 LLA and LLB Series Tire Couplings

LLA series tire couplings utilize internal pressure plates and bolts to connect the two semi-couplings to both sides of the elastic tire body. A key advantage of this design is the ease of tire body replacement—there is no need to disassemble the entire coupling or move the connected shafts, significantly reducing maintenance time and costs . LLB series tire couplings, on the other hand, feature a structure where the two semi-couplings and the tire body are fixed together directly with bolts. This design offers good shock absorption and inter-shaft offset compensation performance, with a focus on simplicity and reliability. The shaft hole types of LLB series couplings are often customizable to meet specific application needs .

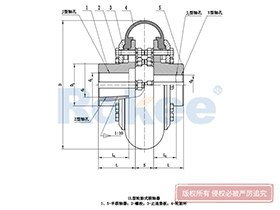

3.4 Brake Wheel-Integrated Tire Couplings

For applications requiring rapid braking, tire couplings can be integrated with a brake wheel. This type of coupling combines the torque transmission and misalignment compensation functions of a standard tire coupling with the braking capability of a brake wheel, eliminating the need for separate braking components. The brake wheel is typically mounted on one of the metal hubs, allowing for direct and efficient braking of the transmission system. This integrated design is commonly used in lifting equipment, conveyors, and other machinery that requires precise and quick stop capabilities .

4. Performance Characteristics of Tire Couplings

Tire couplings exhibit a unique set of performance characteristics that make them suitable for a wide range of industrial applications. These characteristics are primarily derived from the properties of the elastomeric tire body and the structural design of the coupling. The key performance advantages and limitations are as follows:

4.1 Key Advantages

High Elasticity and Misalignment Compensation: The elastomeric tire body provides excellent elasticity, enabling tire couplings to compensate for axial, radial, and angular misalignments between shafts. This capability is crucial in industrial settings where shaft alignment can be affected by factors such as foundation settlement, thermal expansion, and mechanical wear. By accommodating these misalignments, tire couplings reduce stress on shafts, bearings, and other transmission components, extending their service life .

Superior Vibration Damping and Shock Absorption: The rubber-based tire body has inherent damping properties, allowing it to absorb and dissipate vibrations and shock loads generated during machinery operation. This reduces noise levels in the workplace and protects sensitive equipment components from damage caused by repeated impact. In applications with frequent start-ups, stops, or variable loads—such as crushers, ball mills, and conveyors—this damping effect is particularly valuable .

Simple Structure and Easy Maintenance: Tire couplings have a straightforward design with fewer components compared to complex coupling types like gear couplings or universal joints. They do not require lubrication, eliminating the need for regular lubrication maintenance and reducing the risk of oil contamination in the working environment. Additionally, the tire body can be easily replaced without disassembling the entire coupling or moving the connected shafts, minimizing downtime during maintenance .

Wide Operating Temperature Range: Most tire couplings can operate stably within a temperature range of -20℃ to 80℃, making them suitable for both indoor and outdoor applications. Specialized tire body materials can be used to extend this range for extreme temperature environments, such as high-temperature applications in metallurgy or low-temperature applications in cold storage facilities .

4.2 Limitations

Limited Load-Bearing Capacity: Compared to rigid couplings or metal flexible couplings, tire couplings have a lower load-bearing capacity. The elastomeric tire body is the primary limiting factor, as it can only withstand a certain level of torsional stress before experiencing permanent deformation or failure. This makes tire couplings unsuitable for high-torque applications beyond their rated capacity .

Large Physical Dimensions: To achieve their elastic and damping properties, tire couplings typically have larger external dimensions compared to other coupling types with similar torque ratings. This can be a disadvantage in applications with limited installation space, such as compact machinery or densely packed equipment layouts .

Additional Axial Forces: As the relative twist angle between the two shafts increases, the tire body becomes distorted, leading to a slight reduction in axial dimension. This distortion generates additional axial forces on the shafts, which can increase the load on the bearings and reduce their service life. At high rotational speeds, the centrifugal force acting on the outer edge of the tire body further amplifies these additional axial forces. To mitigate this issue, special installation measures can be adopted, such as pre-stressing the tire body in the opposite direction of operational stress .

Susceptibility to Chemical Degradation: The elastomeric tire body can be damaged by exposure to certain chemicals, such as oils, solvents, acids, and alkalis. In environments where such chemicals are present, specialized chemical-resistant rubber materials must be used to ensure the coupling's performance and service life .

5. Application Fields of Tire Couplings

The unique combination of flexibility, damping capacity, and ease of maintenance makes tire couplings suitable for a wide range of industrial applications. They are particularly well-suited for working conditions involving vibration, shock loads, shaft misalignment, and frequent start-ups and stops. The main application fields are as follows:

5.1 Metallurgy Industry

In the metallurgy industry, tire couplings are widely used in equipment such as rolling mills, coking equipment, and blast furnace auxiliary machinery. These applications involve high temperatures, heavy loads, and significant vibration. Tire couplings effectively absorb the shock loads generated during the rolling process, compensate for the misalignment caused by thermal expansion of the shafts, and protect expensive equipment components such as reducers and motors. For example, in hot strip mills, tire couplings are used to connect the motor and the rolling mill, reducing the torsional vibration caused by the biting and throwing of steel, thereby improving the quality of the strip steel .

5.2 Mining Industry

Mining equipment such as crushers, ball mills, and conveyors operates under harsh conditions with intense vibration, shock loads, and high levels of dust. Tire couplings are ideal for these applications due to their excellent shock absorption and dust resistance (no lubrication required). In large ball mills, for instance, tire couplings help to smooth the start-up process by absorbing the high impact torque generated when the mill overcomes the static friction of hundreds of tons of steel balls and materials. This reduces the load on the motor and the reducer, extending their service life .

5.3 Power Generation Industry

In power plants, tire couplings are used in equipment such as turbines, generators, and feedwater pumps. These applications require precise torque transmission and reliable operation. Tire couplings compensate for the misalignment between the turbine and the generator caused by thermal expansion and foundation settlement, while absorbing the vibration generated during operation. This ensures the stable operation of the power generation system and improves the efficiency of power transmission .

5.4 General Manufacturing and Machinery

Tire couplings are widely used in general manufacturing equipment such as pumps, compressors, fans, and machine tools. In pump systems, for example, they compensate for the misalignment between the motor and the pump shaft, reducing vibration and noise and improving the efficiency of the pump. In machine tools, tire couplings help to maintain the precision of the machining process by reducing vibration and ensuring smooth torque transmission .

5.5 Transportation and Port Machinery

In transportation and port applications, such as port gantry cranes, container handlers, and excavators, tire couplings are used to connect the hydraulic system or motor to the working mechanism. These applications involve frequent start-ups, stops, and direction changes, generating significant shock loads. Tire couplings absorb these shocks, reduce vibration, and improve the stability and positioning accuracy of the equipment. For example, in port gantry cranes, tire couplings reduce the vibration of the boom during load handling, improving operator comfort and extending the service life of the crane structure .

6. Selection Criteria for Tire Couplings

Selecting the appropriate tire coupling for a specific application is crucial to ensuring optimal performance, reliability, and service life. The selection process should take into account several key factors, including torque requirements, shaft misalignment, operating conditions, and installation space. The following are the main selection criteria:

6.1 Torque Capacity

The first and most critical factor is the torque capacity of the coupling. The rated torque of the selected coupling must be greater than the maximum working torque of the transmission system. This includes considering not only the rated torque of the motor but also the peak torque generated during start-ups, stops, or load fluctuations. It is recommended to select a coupling with a torque margin of 1.2 to 1.5 times the maximum working torque to ensure reliability .

6.2 Shaft Misalignment

The selected tire coupling must be capable of compensating for the maximum expected axial, radial, and angular misalignments of the shafts. This requires understanding the sources of misalignment, such as foundation settlement, thermal expansion, and mechanical wear, and calculating the maximum possible misalignment values. It is important to select a coupling with misalignment compensation capabilities that exceed the expected values to avoid premature failure .

6.3 Operating Speed

The maximum operating speed of the coupling must be compatible with the rotational speed of the shafts. At high speeds, the centrifugal force acting on the tire body increases, which can lead to additional axial forces and reduced stability. It is essential to select a coupling with a rated speed that is higher than the maximum operating speed of the system to ensure safe and stable operation .

6.4 Operating Environment

The operating environment has a significant impact on the selection of the tire body material and coupling design. Factors such as temperature, humidity, dust, and chemical exposure must be considered. For high-temperature environments, heat-resistant rubber materials should be used. For environments with chemical exposure, chemical-resistant materials are required. In dusty or humid environments, the coupling's sealing performance should be considered to prevent contamination of the tire body .

6.5 Installation Space

The physical dimensions of the coupling (diameter, length) must fit within the available installation space. In compact machinery, it may be necessary to select a compact tire coupling model or customize the coupling dimensions to meet the space constraints .

6.6 Maintenance Requirements

The maintenance requirements of the application should also be considered. For applications where downtime must be minimized, tire couplings with easy-to-replace tire bodies (such as LLA series) are preferred. For remote or hard-to-access locations, maintenance-free tire couplings are ideal .

7. Maintenance Practices for Tire Couplings

Although tire couplings are relatively low-maintenance compared to other coupling types, proper maintenance is still essential to ensure their long-term performance and reliability. The main maintenance practices include regular inspection, tire body replacement, and proper installation checks.

7.1 Regular Inspection

Regular visual and functional inspections should be conducted to identify potential issues early. Inspection items include: checking the tire body for cracks, bulges, or signs of wear; inspecting the bolts for tightness and signs of corrosion; checking the hub connections for slippage; and monitoring the coupling for abnormal vibration or noise during operation. In harsh environments, inspections should be conducted more frequently—ideally monthly or quarterly. In less demanding environments, semi-annual or annual inspections may be sufficient .

7.2 Tire Body Replacement

The tire body is the wear component of the coupling and will eventually need to be replaced due to fatigue or damage. Signs that indicate the need for tire body replacement include reduced elasticity, permanent deformation, cracks, or a significant increase in vibration. When replacing the tire body, it is important to use a compatible replacement part that matches the coupling model and specifications. The replacement process should follow the manufacturer's guidelines, ensuring that the bolts are tightened to the correct torque to maintain the required frictional force for torque transmission .

7.3 Installation and Alignment Checks

Proper installation and shaft alignment are critical to the performance and service life of tire couplings. During installation, the shafts should be aligned as accurately as possible to minimize the load on the tire body. After installation, a final alignment check should be conducted to ensure that the misalignment is within the coupling's compensation range. Additionally, the installation should include measures to mitigate additional axial forces, such as pre-stressing the tire body if necessary .

8. Future Trends in Tire Coupling Technology

As industrial machinery becomes more efficient, intelligent, and demanding, tire coupling technology is evolving to meet these new requirements. The main future trends include material innovation, structural optimization, and the integration of intelligent monitoring capabilities.

8.1 Material Innovation

Research and development in elastomeric materials are focused on improving the load-bearing capacity, fatigue resistance, and environmental resistance of tire bodies. New composite materials, such as rubber reinforced with carbon fiber or aramid fibers, are being explored to increase the tensile strength and reduce the weight of the tire body. Additionally, the development of specialized rubber formulations with enhanced heat resistance, chemical resistance, and low-temperature performance will expand the application range of tire couplings to more extreme environments .

8.2 Structural Optimization

Structural optimization is aimed at reducing the physical dimensions of tire couplings while maintaining or improving their performance. Advanced design tools such as finite element analysis (FEA) are being used to optimize the shape of the tire body and the hub connections, reducing stress concentrations and improving load distribution. This will allow tire couplings to be used in more compact machinery and high-torque applications .

8.3 Intelligent Monitoring Integration

The integration of intelligent monitoring sensors into tire couplings is a growing trend. These sensors can monitor parameters such as tire body deformation, temperature, vibration, and bolt tightness in real-time. The data collected by these sensors can be transmitted to a central monitoring system, allowing for predictive maintenance and early detection of potential failures. This intelligent monitoring capability will reduce downtime, improve operational efficiency, and extend the service life of both the coupling and the connected equipment .

9. Conclusion

Tire couplings are essential components in modern mechanical transmission systems, offering a unique combination of flexibility, damping capacity, and ease of use. Their ability to transmit torque while compensating for shaft misalignment and absorbing vibrations makes them indispensable in a wide range of industrial applications, from heavy metallurgy and mining to general manufacturing and power generation. Understanding the structural components, working principle, performance characteristics, and selection criteria of tire couplings is crucial for ensuring optimal performance and reliability in specific applications.

While tire couplings have certain limitations, such as limited load-bearing capacity and large physical dimensions, ongoing technological advancements in materials and structural design are addressing these issues. The integration of intelligent monitoring capabilities is further enhancing their value by enabling predictive maintenance and improving operational efficiency. As industrial machinery continues to evolve, tire couplings will remain a key component in optimizing transmission systems, contributing to increased reliability, reduced maintenance costs, and improved overall productivity.

« Tire Couplings » Post Date: 2023/10/9

URL: http://www.rokee.com/en/tags/tire-couplings.html