Barrel Couplings

Rokee is Barrel Couplings Manufacturer, Customizable according to the barrel couplings drawings provided by the customer, Support Export.

The Barrel Coupling is a new type of flexible coupling, mainly used for connecting the reducer output shaft of the lifting mechanism in lifting equipment with the steel wire rope drum, it is also applicable to other similar mechanical devices that transmit torque while bearing radial loads, but it cannot be used as a transmission that needs to withstand axial loads.

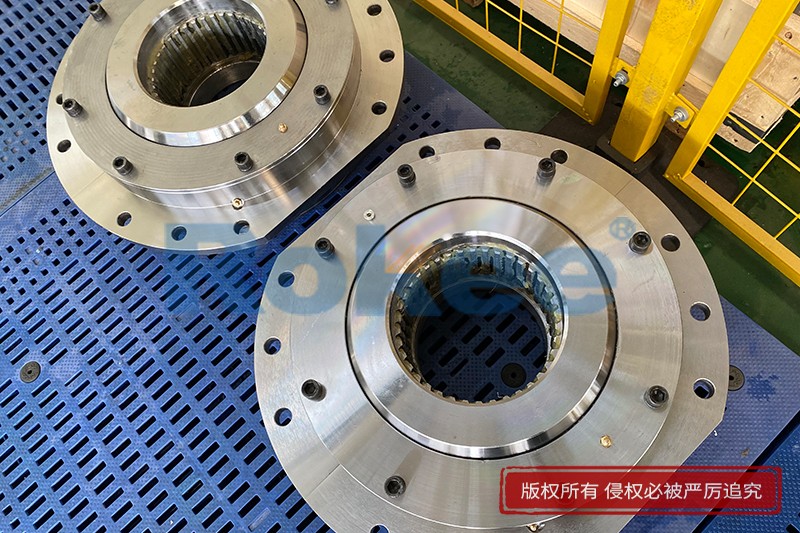

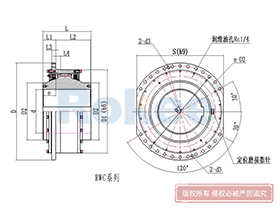

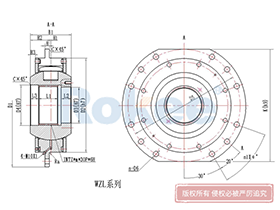

RWC Drum Coupling

Ball and Drum Gear

The ball and drum gear drum coupling is a drum coupling developed by Rokee with a more reliable structure, higher compensation ability and higher safety factor. The outer sleeve adopts a spherical drum tooth design, which has low requirements for shafting installation accuracy, large transmission torque, strong overload capacity and can withstand great radial load. The connection size is the same as that of DC series, but the bearing capacity is increased by more than 30%. The innovative spherical sealing technology makes this type of product maintain excellent lubrication and greatly improve its service life.View MoreDQ/WZL Drum Coupling

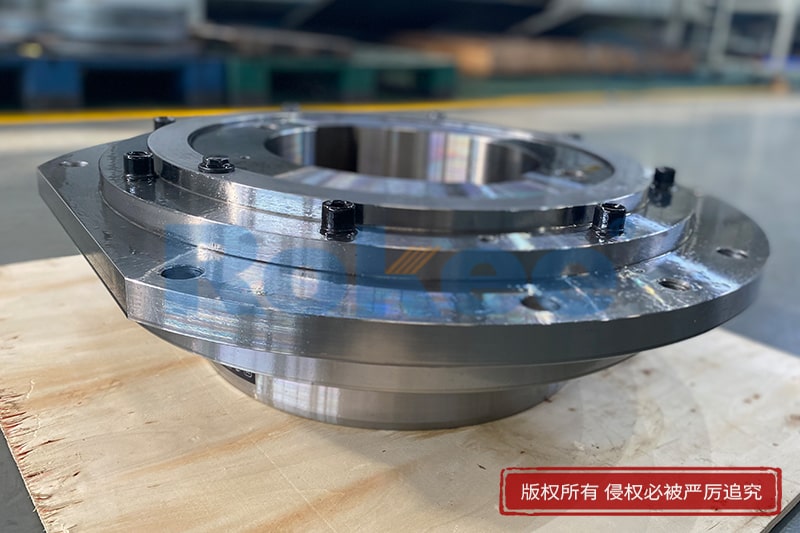

Ball Dumpling

WZL Drum Coupling is a spherical hinged coupling. It has a connecting flange with an inner spherical surface, a spherical semi-coupling sleeve with an outer spherical surface, a special transmission key, an inner and outer limit cover, etc. The internal control generally adopts the splined sleeve design, which transmits torque through a specially designed key bar and can withstand large torque and radial load. The maximum angular displacement compensation can reach 3°, with a life indicator and safe and reliable structure.View MoreDC Drum Coupling

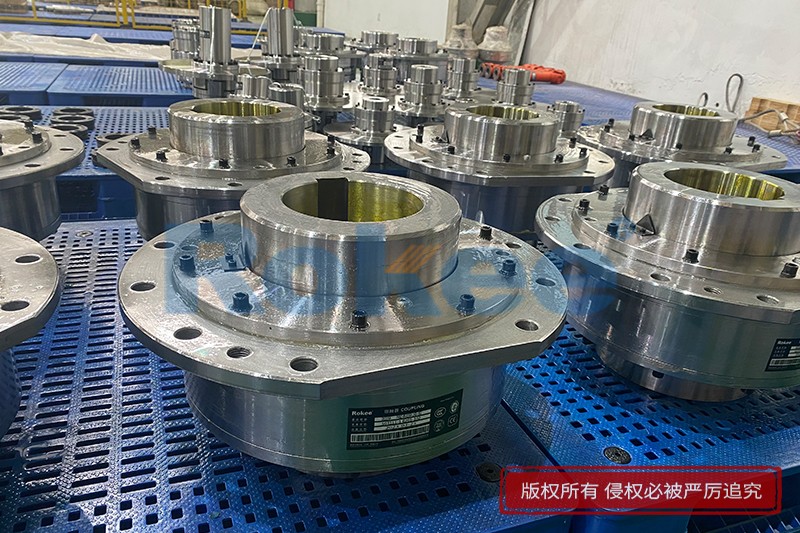

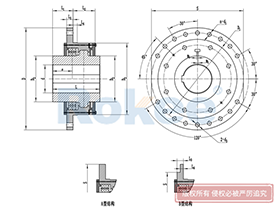

Drum-type

DC Drum Coupling is designed with drum teeth, which is used for connecting the reducer of crane transmission system with the drum. It can bear radial load and transfer large torque, but cannot transfer axial load.View MoreWJ Drum Coupling

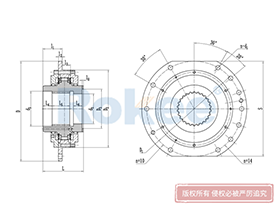

Spherical Roller

WJ Drum Coupling is a spherical roller coupling, which is composed of jacket with connecting flange, spherical roller, semi-coupling, inner and outer cover plate and sealing system, capable of transmitting large torque and bearing radial load.View MoreWJA Drum Coupling

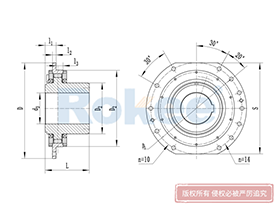

Spherical Roller

WJA Drum Coupling is a spherical roller coupling, which is composed of jacket with connecting flange, spherical roller, semi-coupling, inner and outer cover plate and sealing system, capable of transmitting large torque and bearing radial load. The connection between the coupling and the output shaft of the reducer adopts an involute spline pair design.View More

In the realm of mechanical power transmission and fluid handling systems, couplings serve as critical intermediaries that ensure the seamless transfer of energy, fluids, or signals between components. Among the diverse array of coupling types available, barrel coupling stands out for its unique structural design and versatile performance characteristics. Whether facilitating torque transmission in heavy-duty industrial machinery or enabling leak-tight fluid connections in piping systems, barrel couplings play an indispensable role in numerous industrial and commercial applications.

1. Understanding Barrel Coupling: Definition and Core Functions

A barrel coupling is a type of connecting component designed to join two or more parts in a system, facilitating the transfer of torque, fluid, or electrical power while accommodating specific operational requirements such as misalignment, vibration absorption, or easy assembly. The term "barrel" derives from the cylindrical, barrel-like shape that is characteristic of most designs, which contributes to both their structural integrity and functional efficiency. Unlike some specialized couplings that are limited to narrow application ranges, barrel couplings exhibit remarkable versatility, with variations tailored to meet the demands of both mechanical power transmission and fluid handling systems.

The core functions of barrel couplings vary depending on their specific application context but generally include three primary aspects. First, in mechanical transmission systems, they serve to transmit torque between rotating shafts, such as connecting a gearbox output shaft to a cable drum in hoisting equipment. Second, in fluid handling systems, they establish leak-tight connections between pipes, hoses, or tubes, ensuring the efficient and safe transfer of liquids or gases. Third, many barrel coupling designs are engineered to accommodate misalignment between connected components, whether angular, axial, or radial, which helps reduce wear and tear on other system parts and extends overall operational lifespan. Additionally, some variants incorporate features for easy assembly and disassembly, simplifying maintenance and reducing downtime.

2. Structural Design and Working Mechanisms of Barrel Couplings

The structural design of barrel couplings is highly dependent on their intended application, with distinct configurations for mechanical transmission and fluid handling purposes. Despite these differences, all barrel couplings share the common characteristic of a cylindrical main body, which provides the necessary structural rigidity and contact surface for effective connection.

2.1 Mechanical Transmission Barrel Couplings

Mechanical transmission barrel couplings are typically composed of three key components: a sleeve with internal semicircular toothing, a hub with external toothing, and a series of cylindrical barrels made from hardened steel. The sleeve and hub are designed such that their toothing forms matching holes when assembled, into which the cylindrical barrels are inserted. These barrels act as the primary torque-transmission elements, transferring rotational force from the driving shaft (connected to the hub) to the driven shaft (connected to the sleeve) or vice versa.

The working mechanism of this design leverages the contact between the cylindrical barrels and the toothed surfaces of the hub and sleeve. When torque is applied, the barrels roll within the toothed grooves, distributing the load evenly across a large contact area. This even load distribution minimizes bending stress at the base of the teeth, a common point of failure in other types of toothed couplings. Additionally, the convex shape of the barrels and the curved profile of the toothing allow for a significant degree of misalignment compensation. Angular misalignments of up to 1.5 degrees and moderate axial displacements can be accommodated, making these couplings well-suited for applications where precise shaft alignment is difficult to maintain, such as in crane and hoist systems.

To ensure long-term reliability, mechanical barrel couplings are often equipped with protective covers and sealing systems. These covers, fitted with lip seals, prevent the ingress of dust, debris, and other contaminants into the internal components while retaining the necessary lubrication. Proper lubrication is critical for reducing friction between the barrels and the toothed surfaces, minimizing wear and extending the coupling's service life. Many designs also incorporate a wear indicator, a simple yet effective feature that allows operators to monitor internal wear without disassembling the coupling. This indicator typically consists of a marker on the external cover that moves relative to reference marks on the hub as wear occurs, providing a visual cue for maintenance needs.

2.2 Fluid Handling Barrel Couplings

Fluid handling barrel couplings, also known as barrel unions, are designed to connect pipes, hoses, or tubes in fluid transfer systems. Their structural design is focused on creating a leak-tight seal while enabling easy assembly and disassembly. The basic structure typically includes a cylindrical barrel-shaped body with threaded ends, flanges, or push-to-connect fittings, depending on the application requirements.

Threaded barrel couplings are among the most common variants, featuring internal or external threads that allow for secure attachment to threaded pipes. The threads create a tight seal when tightened, and additional sealing elements such as gaskets or O-rings may be incorporated to enhance leak resistance, particularly in high-pressure applications. Flanged barrel couplings, on the other hand, use bolted flanges to create a rigid, leak-tight connection, making them suitable for high-pressure and high-temperature fluid systems. Push-to-connect barrel couplings are designed for quick installation without the need for specialized tools, making them ideal for temporary installations or applications where frequent disassembly is required.

The working mechanism of fluid handling barrel couplings revolves around maintaining the integrity of the fluid path while accommodating the operational conditions of the system. They must withstand the pressure and temperature of the fluid being transferred, resist corrosion from chemical components, and prevent leaks that could lead to safety hazards or operational inefficiencies. The cylindrical shape of the barrel body ensures a smooth fluid flow, minimizing pressure drops and turbulence within the system.

3. Key Material Considerations for Barrel Couplings

The selection of materials for barrel couplings is a critical factor that directly impacts their performance, durability, and suitability for specific applications. Materials are chosen based on a range of factors, including the operational environment (temperature, humidity, chemical exposure), load requirements (torque, pressure), and compatibility with the connected components or fluids. The most commonly used materials for barrel couplings include various types of steel, brass, copper, PVC, and engineered plastics.

3.1 Metals for High-Performance Applications

Steel, particularly hardened carbon steel and stainless steel, is the primary material for mechanical transmission barrel couplings. Hardened steel is used for the cylindrical barrels and toothed components of mechanical couplings due to its high strength, wear resistance, and ability to withstand high torque loads. Stainless steel, which contains chromium and other alloying elements, offers enhanced corrosion resistance, making it suitable for applications in harsh environments such as coastal areas, chemical plants, or food processing facilities where moisture or chemical exposure is a concern.

Brass and copper are commonly used for fluid handling barrel couplings, particularly in plumbing, water treatment, and heating systems. Brass, an alloy of copper and zinc, is valued for its durability, corrosion resistance, and machinability. It is also non-magnetic, making it suitable for applications where magnetic interference must be avoided. Copper, known for its excellent thermal conductivity, is often used in heating systems and applications where heat transfer is a secondary requirement. Both brass and copper are compatible with most potable water systems, making them popular choices for residential and commercial plumbing applications.

3.2 Polymers and Plastics for Specialized Applications

Polyvinyl Chloride (PVC) is a widely used plastic material for fluid handling barrel couplings in low-pressure, low-temperature applications. PVC is lightweight, corrosion-resistant, and cost-effective, making it ideal for water supply systems, drainage systems, and chemical processing applications where the fluid is non-corrosive. Engineered plastics, such as polypropylene and PTFE, are used for more demanding applications. Polypropylene offers excellent chemical resistance and can withstand higher temperatures than PVC, while PTFE (Teflon) is virtually inert to most chemicals and has a very low coefficient of friction, making it suitable for high-purity and corrosive fluid applications.

The choice of material must also consider the compatibility with the fluid or environment in which the coupling will operate. For example, in oil and gas applications where the coupling is exposed to harsh chemicals and high pressures, high-performance alloys or stainless steel are preferred. In contrast, in residential plumbing applications, PVC or brass couplings are more than sufficient and offer a more cost-effective solution.

4. Major Applications of Barrel Couplings

The versatility of barrel couplings makes them suitable for a wide range of applications across multiple industries. From heavy-duty industrial machinery to everyday plumbing systems, these components play a critical role in ensuring the reliable operation of various systems. The following sections outline the key application areas for both mechanical transmission and fluid handling barrel couplings.

4.1 Industrial Machinery and Heavy-Duty Equipment

Mechanical transmission barrel couplings are extensively used in industrial machinery and heavy-duty equipment, particularly in applications involving torque transmission and shaft connection. One of the most common applications is in crane and hoist systems, where barrel couplings connect the gearbox output shaft to the cable drum. These systems require couplings that can transmit high torque loads while accommodating the misalignment that occurs during operation. Barrel couplings are ideal for this purpose due to their high torque capacity, misalignment compensation capabilities, and integrated wear indicators, which help ensure the safety and reliability of lifting operations.

Steel mills are another major application area for mechanical barrel couplings. In steel production processes, various types of machinery, such as rolling mills, conveyors, and winches, require reliable torque transmission between shafts. Barrel couplings are used in these applications to handle the high torque and radial loads generated during steel processing, as well as to withstand the high-temperature and dusty environment typical of steel mills. Additionally, barrel couplings are used in winch and conveyor systems across a range of industries, including mining, logistics, and construction, where they facilitate the movement of heavy loads and materials.

4.2 Fluid Handling Systems

Fluid handling barrel couplings are essential components in piping systems for the transfer of liquids and gases. The oil and gas industry is a major user of these couplings, particularly in upstream exploration and production activities, as well as downstream refining and distribution. In offshore and deep-water operations, high-pressure, high-temperature (HPHT) barrel couplings are used to connect subsea pipelines, wellhead equipment, and other critical components, ensuring the safe and efficient transfer of oil and gas under extreme conditions.

Water treatment and wastewater management systems also rely heavily on fluid handling barrel couplings. These couplings are used to connect pipes in water treatment plants, distribution networks, and sewage systems, ensuring the leak-tight transfer of water and wastewater. The corrosion resistance of materials such as stainless steel and PVC makes these couplings suitable for use in these applications, where exposure to moisture and chemicals is constant. In addition, barrel couplings are used in chemical processing plants to connect pipes carrying corrosive chemicals, with materials selected based on the specific chemical compatibility requirements.

4.3 Commercial and Residential Applications

Barrel couplings are also widely used in commercial and residential settings. In plumbing systems, brass and PVC barrel couplings are used to connect pipes for water supply, heating, and drainage. Push-to-connect barrel couplings have become increasingly popular in these applications due to their ease of installation, which reduces labor costs and installation time. In addition, barrel couplings are used in HVAC (Heating, Ventilation, and Air Conditioning) systems to connect refrigerant lines, ensuring the efficient transfer of refrigerant between components.

Another common residential and commercial application is in beverage dispensing systems, such as beer taps and soda fountains. Barrel couplings in these systems connect the beverage supply lines to the dispensing unit, ensuring a leak-tight connection and maintaining the quality and freshness of the beverage. These couplings are typically made from food-grade materials such as stainless steel or brass to ensure compliance with health and safety standards.

5. Selection Criteria for Barrel Couplings

Selecting the right barrel coupling for a specific application is crucial to ensuring optimal performance, reliability, and safety. The selection process involves considering a range of factors, including operational requirements, environmental conditions, and compatibility with other system components. The following are the key criteria to consider when selecting a barrel coupling:

5.1 Operational Load Requirements

For mechanical transmission barrel couplings, the primary load consideration is the torque capacity. The coupling must be capable of handling the maximum torque generated by the system without failure. It is important to select a coupling with a torque rating that exceeds the maximum operational torque to provide a safety margin. Additionally, radial load capacity is a critical factor in applications such as cranes and hoists, where the coupling must support the weight of the load and the rotating components.

For fluid handling barrel couplings, pressure rating is the key load criterion. The coupling must be rated for the maximum pressure of the fluid being transferred to prevent leaks or structural failure. Temperature rating is also important, as the coupling material must maintain its integrity at the operational temperature of the fluid. High-temperature applications, such as steam systems or oil refining, require couplings made from materials that can withstand elevated temperatures without deforming or losing their sealing properties.

5.2 Misalignment and Compensation Requirements

In mechanical transmission systems, shaft misalignment is a common issue that can lead to increased wear and reduced component lifespan. Barrel couplings vary in their ability to compensate for angular, axial, and radial misalignment, so it is important to select a coupling that can accommodate the expected misalignment in the system. For applications where misalignment is significant, such as in crane drum connections, a barrel coupling with a high misalignment compensation capability is essential.

5.3 Environmental Conditions

The operational environment has a significant impact on the performance and durability of barrel couplings. Factors such as temperature, humidity, dust, debris, and chemical exposure must be considered when selecting the coupling material and design. In corrosive environments, such as coastal areas or chemical plants, corrosion-resistant materials such as stainless steel or engineered plastics are preferred. In dusty or dirty environments, couplings with effective sealing systems are necessary to prevent contamination of internal components.

5.4 Assembly and Maintenance Requirements

The ease of assembly and disassembly is an important consideration for applications where maintenance or replacement is frequent. Push-to-connect barrel couplings are ideal for these applications, as they can be installed and removed without specialized tools. For mechanical transmission couplings, features such as integrated wear indicators simplify maintenance by allowing operators to monitor wear without disassembling the coupling. Additionally, the availability of replacement parts and the ease of lubrication should be considered to minimize downtime.

5.5 Compatibility with Connected Components

The barrel coupling must be compatible with the connected shafts, pipes, or hoses in terms of size, shape, and connection type. For mechanical couplings, the bore diameter must match the shaft diameter to ensure a secure fit. For fluid handling couplings, the thread size, flange type, or tube diameter must be compatible with the connected piping components. Incompatible couplings can lead to leaks, reduced performance, or premature failure.

6. Maintenance and Troubleshooting of Barrel Couplings

Proper maintenance is essential to ensure the long-term reliability and performance of barrel couplings. Regular maintenance practices help prevent premature wear, reduce downtime, and extend the service life of the coupling. The following are the key maintenance and troubleshooting guidelines for barrel couplings:

6.1 Regular Inspection

Regular visual inspections are the first line of defense in maintaining barrel couplings. For mechanical transmission couplings, operators should check the wear indicator regularly to monitor internal wear. If the indicator shows that wear has exceeded the acceptable limit, the coupling should be replaced immediately to prevent failure. Additionally, inspections should include checking for signs of leakage, corrosion, or damage to the sealing system. For fluid handling couplings, visual inspections should focus on detecting leaks, which can indicate a damaged seal or loose connection.

6.2 Lubrication

Proper lubrication is critical for mechanical transmission barrel couplings. The cylindrical barrels and toothed surfaces rely on lubrication to reduce friction and wear. Lubricant levels should be checked regularly, and the lubricant should be replaced according to the manufacturer's recommendations. The type of lubricant used should be compatible with the coupling material and the operational environment. In high-temperature applications, a high-temperature lubricant is necessary to maintain its viscosity and lubricating properties.

6.3 Tightening and Torque Checks

For threaded and flanged barrel couplings, regular torque checks are necessary to ensure that connections remain tight. Vibration and thermal expansion and contraction can cause connections to loosen over time, leading to leaks or reduced performance. Operators should use a torque wrench to re-tighten connections to the recommended torque value at regular intervals. For push-to-connect couplings, inspections should ensure that the coupling is fully engaged and that the release mechanism is functioning properly.

6.4 Troubleshooting Common Issues

Common issues with barrel couplings include wear, leakage, and misalignment-related problems. Excessive wear in mechanical couplings can be caused by insufficient lubrication, overloading, or misalignment beyond the coupling's capacity. To resolve this issue, the root cause should be identified and addressed, and the worn coupling should be replaced. Leakage in fluid handling couplings is often caused by damaged seals, loose connections, or incompatible materials. Replacing the seal, re-tightening the connection, or selecting a coupling made from a compatible material can resolve this issue.

Misalignment-related problems, such as excessive vibration or noise, can be resolved by realigning the connected shafts or selecting a coupling with a higher misalignment compensation capability. In some cases, improper installation can lead to misalignment, so ensuring that the coupling is installed correctly according to the manufacturer's guidelines is essential.

7. Future Trends in Barrel Coupling Design and Technology

The barrel coupling industry is continuously evolving to meet the changing demands of modern industrial applications. One of the key trends is the development of more advanced materials and manufacturing processes. Manufacturers are increasingly using high-performance alloys and engineered plastics to enhance the strength, corrosion resistance, and temperature tolerance of barrel couplings. These materials allow couplings to operate in more extreme environments, such as deep-water oil and gas operations and high-temperature industrial processes.

Another trend is the integration of smart technologies into barrel coupling design. Smart couplings equipped with sensors can monitor key performance parameters such as temperature, vibration, and wear in real time. This data can be transmitted to a central monitoring system, allowing operators to predict potential failures and schedule maintenance proactively. This predictive maintenance approach helps reduce downtime and improve the overall efficiency of the system.

Additionally, there is a growing focus on sustainability in barrel coupling design. Manufacturers are developing couplings that are more energy-efficient, with designs that minimize friction and reduce energy consumption. There is also a trend toward using recyclable materials and reducing the environmental impact of manufacturing processes. These sustainable design practices align with the broader global movement toward reducing carbon emissions and promoting environmental responsibility.

8. Conclusion

Barrel couplings are essential components in a wide range of mechanical and fluid handling systems, offering versatile solutions for torque transmission, fluid transfer, and component connection. Their unique cylindrical design, combined with advanced material selection and engineering, makes them suitable for applications ranging from heavy-duty industrial machinery to residential plumbing systems. Understanding the structural design, working mechanisms, material considerations, and selection criteria of barrel couplings is crucial for ensuring optimal performance and reliability in any application.

Proper maintenance and troubleshooting practices further extend the service life of barrel couplings, reducing downtime and operational costs. As the industry continues to evolve, advancements in materials, smart technologies, and sustainable design are expected to enhance the performance and capabilities of barrel couplings, making them even more indispensable in the modern industrial landscape. Whether in a steel mill, a water treatment plant, or a residential home, barrel couplings play a vital role in keeping systems running smoothly and efficiently.

« Barrel Couplings » Post Date: 2023/10/9