-

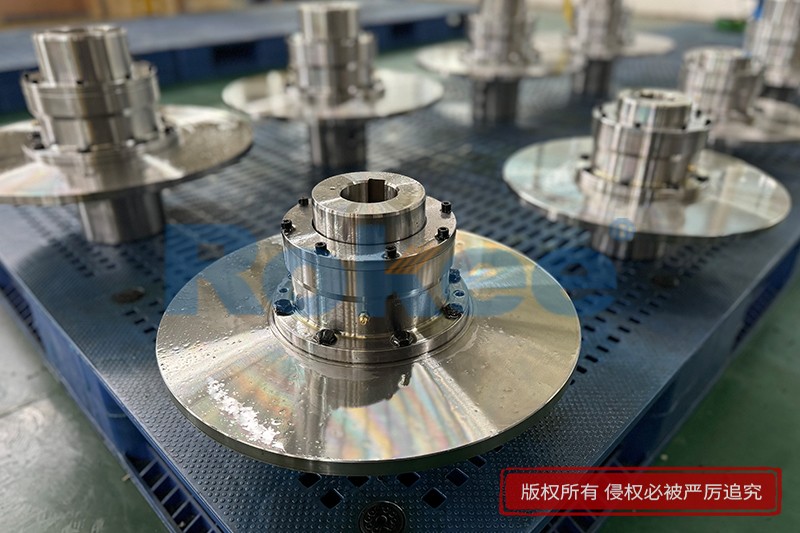

Steel Lamina Coupling

The lamina coupling is an efficient flexible coupling with no back clearance and free from maintenance. Due to its unique structural design, it can achieve the perfect delivery of torque. Meanwhile, it has excellent performances, including large axial and radial compensation ability, low reply feedback force and wide thermal adaptability, etc. With different change design, it can be applied at most power transmission sites. Rokee's RL series steel lamina coupling is a high-quality product developed independently on basis of combination of advanced products from Europe and Japan, etc. It has smaller size, larger torque of the same model, more reasonable proportioning size, large compensation scope, light weight and small rotational inertia.

-

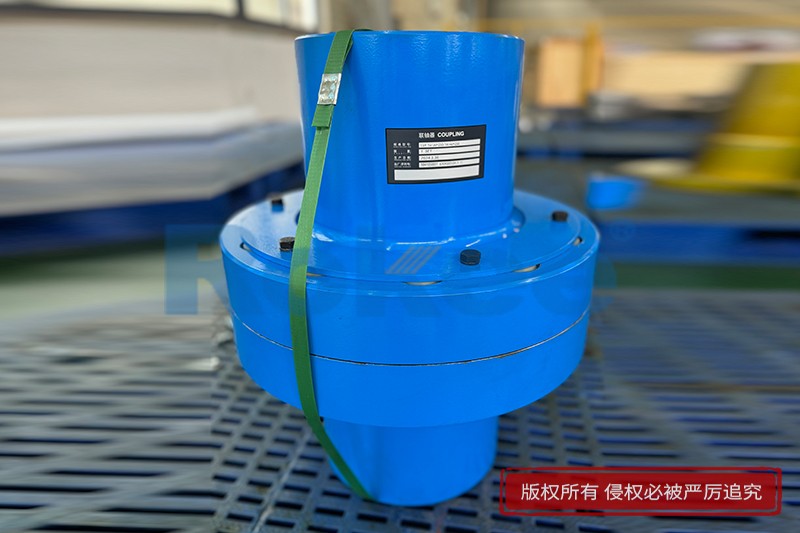

Drum Gear Coupling

As the gear type flexible coupling, it can be applied into various general drive sites. Due to the special hook face drum gear design, in the definitive deviation scope, it can effectively avoid the edge stress concentration at tooth meshing, so it has outstanding radial and angular centering capacity. Moreover, it can ensure long service life. ROD series drum gear coupling is one of Rokee’s core technical products. It has compact and reasonable structure, light weight, small hole-position fitting draw ratio, large pressure angle design, accurate centering and excellent speed performance. The bolt design has been standardized in series, the universality of parts is good and its service life far exceeds the one of domestic products.

-

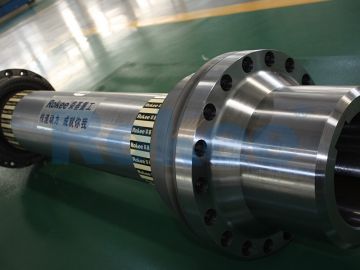

Universal Joint Coupling

Rokee Cardan Shaft are widely used and have many impressive records. From micro products for modern logistics, artificial intelligence machinery, light products used in the paper industry, high speed and high performance products for engineering and railway vehicles, to super heavy duty products used in metallurgical rolling system systems, Rokee has won us with mature products and quality Long-term trust of customers, widely exported to Europe, America and other parts of the world. We have 4 series of nearly 100 standard models and various extended design products based on this for our customers to choose,Torque from *** to ***, diameter from 58mm to 1200mm, ranging from light products to super heavy-duty products...

-

Flexible Couplings

A flexible coupling is a coupling that allows for individual axial displacement of the rotor and allows for a certain deviation in the alignment of two connected rotors. Flexible coupling refers to the ability to compensate for the relative deviation of the two axis lines being connected. There are many types of flexible couplings available on the market. Each has its own features and benefits, but all are required to perform a few primary functions: connect two shafts, transmit rotary power and compensate for some shaft misalignment. A flexible coupling exists to transmit power from one shaft to another; to compensate for minor amounts of misalignment; and in certain cases, to provide protective functions.

-

Crane Drum Coupling

The drum coupling is the crane drum coupling. The internal sphere gear sleeve is assembled with the external drum perfectly. Relying on the specially designed key, the external sphere shaft sleeve forms the entirety with gear sleeve perfectly. It will promote the reliable connection of reducer shaft and drum and it is the most ideal product in the market home and abroad at present. RWC series drum coupling is a type of high-performance drum coupling developed by us and mainly applied for port lifting and large mechanical lifting. In comparison with international DC series products, it has identical outline and connection size, but its interior design is more thorough and steady.

-

Coupling used on steam turbines

Turbine coupling is a specialized product developed by Rokee for matching couplings of steam turbine units. It has been serialized and adapted to steam turbine units of different powers and speeds. After years of verification, the product quality is reliable, meets the operation environment requirements of turbine units and has long service life. The operating environment of the turbine coupling is sometimes very harsh, especially the high temperature and humidity environment and high speed requirements have special manufacturing process requirements for couplings. Besides, the coupling structure cannot be sealed and can only be lubricated openly, thus requiring more special design.

-

Precision Servo Couplings

The coupling is a small but extremely important part in modern servo drive systems. It needs to be extremely accurate and responsive, and transmit the torque, speed and position control signals output by the drive device to achieve as little delay and error as possible. The zero-backlash plum-shaped flexible coupling, metal diaphragm coupling, bellows coupling and other precision servo couplings developed by Rokee are our powerful products in the market. Besides, if you are confused or inconvenient when choosing to use products from Germany, Japan or other companies, we can quickly provide you with more constructive technical alternatives and the same high-quality products to meet your business needs.

-

Non-standard Customized Couplings

Rokee is not only a supplier of couplings, but also a technical designer of transmission system to participate in the overall technical system construction of customers. With our professional knowledge of shafting transmission, we can provide customers with more reliable and cost-effective solutions. For decades, our Technical Department has maintained careful and close communication with our customers and provided customers with draft layouts, drawings, samples, computer modeling and final design results, becoming a trusted supplier to our customers with constantly improving technology and a spirit of sharing. Rokee has established an extensive track record by providing the design and product supply of large main transmission ...