Plum Couplings

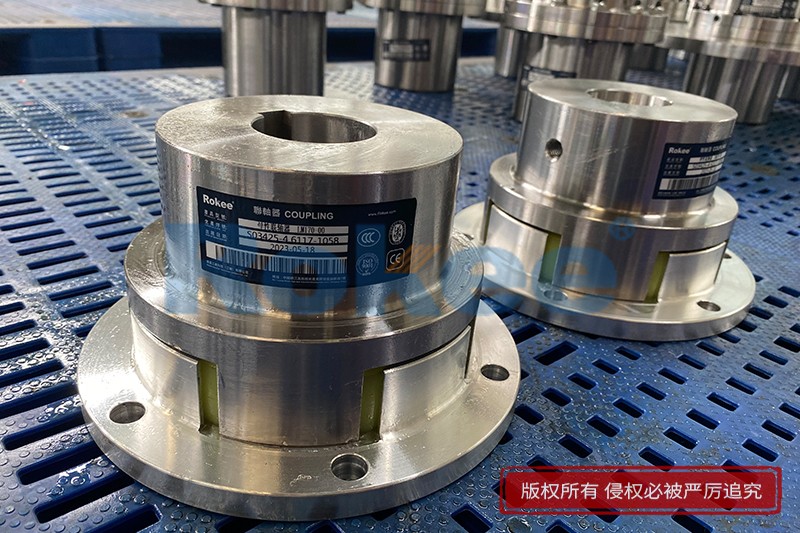

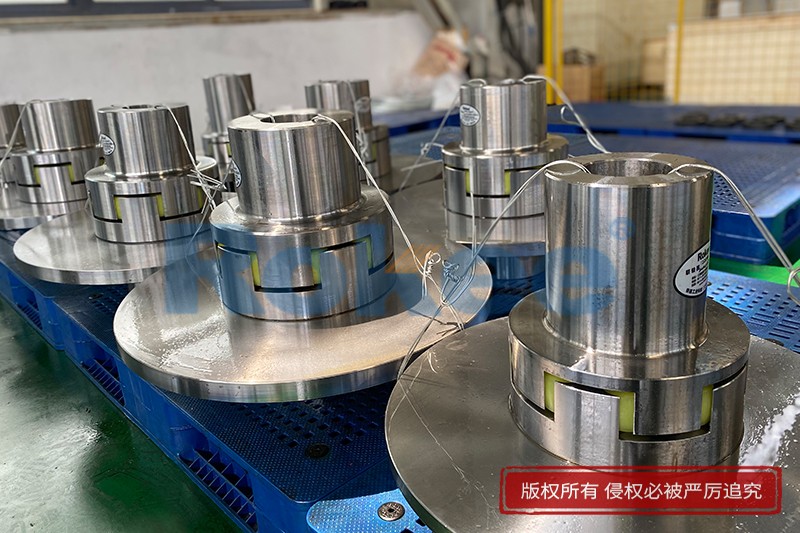

Rokee is Plum Couplings Manufacturer, Customizable according to the plum couplings drawings provided by the customer, Support Export.

Plum Coupling is composed of two semi-couplings with convex claws and a plum-shaped flexible non-metallic element whose hardness can be adjusted. By embedding the plum-shaped flexible element into the two semi-couplings to realize the connection, it has the characteristics of compensating the relative displacement of the two axes, reducing vibration and buffering, simple structure and easy maintenance without lubrication.

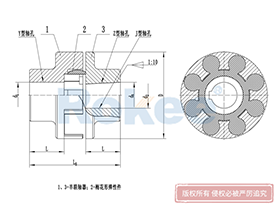

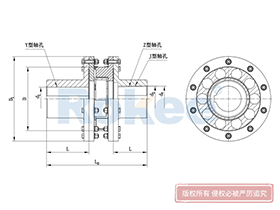

LM/ML Plum-shaped Flexible Coupling

Basic Type

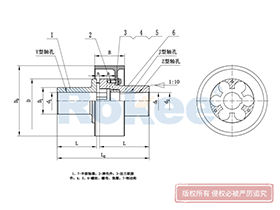

LM Plum-shaped Flexible Coupling is the basic form of this series of couplings.View MoreLMD/MLZ Plum-shaped Flexible Coupling

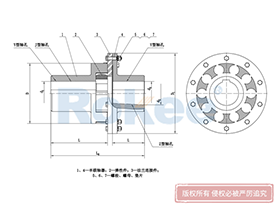

Single Flange

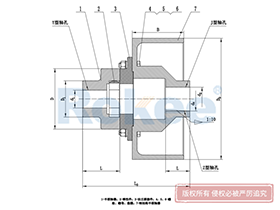

LMD Plum-shaped Flexible Coupling is added with transition connection, which eliminates the need of axially moving the semi-coupling when replacing the elastomer.View MoreLMS/MLS Plum-shaped Flexible Coupling

Double Flange

LMS Plum-shaped Flexible Coupling adopts double transition flange connection, which eliminates the need of axially moving the semi-coupling when replacing the elastomer.View MoreLMZ-I/MLL-I Plum-shaped Flexible Coupling

Split Type, With Brake Wheel

LMZ-I Plum-shaped Flexible Coupling adopts split brake wheel design, suitable for situations where braking is required.View MoreLMZ-II/MLL-II Plum-shaped Flexible Coupling

Integral, With Brake Wheel

LMZ- II Plum-shaped Flexible Coupling adopts integral brake wheel design, suitable for situations where braking is required.View MoreLMPK/MLPK Plum-shaped Flexible Coupling

Split Type, With Brake Discs

LMPK Plum-shaped Flexible Coupling adopts split brake disc design, suitable for situations where braking is required and eliminating the need of axially moving the semi-coupling when replacing the elastomer.View More

In the complex ecosystem of industrial power transmission, couplings serve as the critical link between prime movers (such as motors and engines) and working machinery (including pumps, fans, and conveyors). Among the diverse range of coupling types available, the plum coupling—also commonly referred to as the jaw coupling—has earned widespread adoption due to its unique combination of compact design, flexible performance, and cost-effectiveness. Characterized by its distinctive plum blossom-shaped elastic element, this coupling type excels in compensating for shaft misalignments, dampening vibrations, and protecting transmission systems from shock loads.

1. Structural Composition of Plum Couplings

The plum coupling features a relatively simple yet ingenious structure, consisting of three core components: two metal half-couplings (claw plates), a plum-shaped elastic element (often called a "spider"), and fastening hardware (such as bolts and nuts). Each component plays a vital role in ensuring the coupling’s overall performance and reliability.

The two half-couplings are typically symmetrically designed with convex claws that intermesh with the grooves of the elastic element. These claws are evenly distributed along the circumference of the coupling, ensuring uniform torque transmission. The half-couplings are primarily manufactured from metal materials, with 45# steel being the most common choice due to its excellent mechanical strength, wear resistance, and cost-effectiveness. In applications where weight reduction or corrosion resistance is a priority—such as in precision servo systems or marine environments—aluminum alloy or stainless steel may be used instead. The inner bore of the half-couplings is machined to precise tolerances to ensure a secure fit with the shafts of the connected equipment. Common fitting types include interference fits, transition fits, and clearance fits, each selected based on the specific torque requirements and installation conditions.

The plum-shaped elastic element is the defining feature of this coupling type and the key component responsible for its flexible performance. Typically made from non-metallic materials such as polyurethane, rubber, or engineering plastics, the elastic element is designed with a series of lobes (resembling the petals of a plum blossom) that fit snugly into the claw grooves of the half-couplings. The material properties of the elastic element directly influence the coupling’s torque capacity, vibration damping ability, temperature resistance, and service life. High-strength polyurethane is particularly popular due to its excellent wear resistance, oil resistance, and elastic recovery capabilities, making it suitable for a wide range of industrial environments. The hardness of the elastic element can be adjusted according to specific application needs, with softer materials offering better vibration damping and harder materials providing higher torque transmission capacity.

Fastening hardware, though seemingly trivial, is essential for maintaining the integrity of the coupling assembly. Bolts are used to connect the two half-couplings, ensuring that the elastic element is securely clamped between the claws. The selection of bolts is based on the coupling’s torque rating, with high-strength alloy steel bolts commonly used for heavy-duty applications. To prevent loosening due to vibration during operation, thread lockers or lock washers may be used in the assembly.

2. Working Principles of Plum Couplings

The fundamental working principle of the plum coupling revolves around the transmission of torque through the interaction between the metal half-couplings and the elastic element, while simultaneously compensating for shaft misalignments and dampening vibrations.

Torque transmission begins when the prime mover (e.g., an electric motor) generates rotational force, which is transferred to the driving half-coupling. The claws of the driving half-coupling exert a compressive force on the lobes of the elastic element, causing the element to deform elastically. This elastic deformation transfers the torque to the driven half-coupling, which in turn drives the working machinery. Unlike rigid couplings, which rely on direct metal-to-metal contact for torque transmission, the plum coupling uses the elastic element as an intermediary, allowing for a degree of flexibility in the transmission process.

One of the most important functions of the plum coupling is its ability to compensate for relative displacements between the two connected shafts. In practical industrial applications, perfect alignment between shafts is often difficult to achieve due to factors such as manufacturing errors, installation inaccuracies, thermal expansion and contraction of equipment, and structural deformation under load. The plum coupling can compensate for three types of misalignments: axial displacement (movement along the shaft axis), radial displacement (offset perpendicular to the shaft axis), and angular displacement (tilt between the two shafts). When misalignment occurs, the elastic element deforms correspondingly to accommodate the offset, thereby reducing the additional forces exerted on the shafts, bearings, and other components of the transmission system. This compensation capability not only improves the stability of the transmission system but also extends the service life of associated equipment.

Vibration damping and shock absorption are additional key functions of the plum coupling. During operation, prime movers and working machinery often generate vibrations due to unbalanced rotating parts, intermittent loads, or other factors. These vibrations can cause noise, accelerate component wear, and even lead to structural damage if not properly controlled. The elastic element of the plum coupling acts as a buffer, absorbing and dissipating vibration energy through its elastic deformation. This reduces the amplitude of vibrations transmitted through the coupling, resulting in smoother operation of the entire transmission system. Additionally, the elastic element can absorb shock loads (e.g., during sudden starts or stops), protecting the prime mover and working machinery from potential damage.

Another notable feature of the plum coupling is its electrical insulation performance. Since the elastic element is made from non-metallic materials, it can prevent the transfer of electrical current between the two connected shafts. This is particularly beneficial in applications where electrical isolation is required, such as in equipment with electric motors that may generate stray currents, protecting sensitive components from electrical damage.

3. Material Selection for Plum Couplings

The performance and service life of a plum coupling are largely determined by the materials used for its components. The selection of materials must be based on a comprehensive analysis of the application requirements, including torque capacity, operating speed, temperature range, environmental conditions (e.g., humidity, corrosion, dust), and maintenance accessibility. Below is a detailed overview of material selection for the key components of plum couplings.

3.1 Material Selection for Half-Couplings

As the primary load-bearing components, the half-couplings require materials with high mechanical strength, good wear resistance, and excellent machinability. The most commonly used material is 45# carbon steel, which offers a balance of strength, toughness, and cost-effectiveness. 45# steel can be heat-treated (e.g., quenching and tempering) to further improve its hardness and wear resistance, making it suitable for medium to heavy-duty applications such as in metallurgy, mining, and petroleum industries.

For applications where weight reduction is critical—such as in precision machinery, servo systems, or mobile equipment—aluminum alloy is an ideal alternative. Aluminum alloy materials (e.g., 6061, 7075) are lightweight, have good corrosion resistance, and offer sufficient strength for light to medium torque applications. However, aluminum alloy has lower wear resistance than steel, so it may not be suitable for heavy-duty or high-speed applications with frequent load fluctuations.

In corrosive environments—such as marine, chemical, or food processing industries—stainless steel is preferred. Stainless steel (e.g., 304, 316) offers excellent corrosion resistance and high temperature resistance, ensuring the coupling’s reliability in harsh conditions. However, stainless steel is more expensive than carbon steel and aluminum alloy, which may limit its use in cost-sensitive applications.

3.2 Material Selection for Elastic Elements

The elastic element is the most critical component affecting the coupling’s flexible performance, so its material selection must be carefully considered. The main materials used for elastic elements include polyurethane, rubber, and engineering plastics, each with its own unique properties.

Polyurethane is the most widely used material for plum coupling elastic elements due to its excellent comprehensive performance. It offers high tensile strength, wear resistance, and oil resistance, as well as good elastic recovery and vibration damping capabilities. Polyurethane elastic elements can operate within a temperature range of -35℃ to 80℃, making them suitable for most industrial environments. Additionally, polyurethane can be formulated with different hardness levels (Shore A 60 to 95), allowing for customization based on specific torque and vibration damping requirements. For example, softer polyurethane (Shore A 60-70) is used for applications requiring high vibration damping, while harder polyurethane (Shore A 85-95) is used for high-torque transmission.

Rubber is another common material for elastic elements, offering excellent vibration damping and shock absorption capabilities. Natural rubber is suitable for low-temperature applications, while synthetic rubbers (e.g., nitrile rubber, neoprene) offer better oil resistance and high-temperature resistance. However, rubber has lower wear resistance than polyurethane and is more prone to aging, which may limit its service life in harsh environments.

Engineering plastics (e.g., nylon, POM) are used in specialized applications where high rigidity and chemical resistance are required. Nylon elastic elements offer good wear resistance and mechanical strength, while POM (polyoxymethylene) provides excellent dimensional stability and low friction. However, engineering plastics have lower elastic recovery than polyurethane and rubber, making them less suitable for applications requiring significant vibration damping.

4. Installation and Maintenance of Plum Couplings

Proper installation and regular maintenance are essential for ensuring the optimal performance and long service life of plum couplings. Improper installation—such as misalignment, incorrect fastening, or damage to the elastic element—can lead to premature failure, increased vibration, and even damage to the connected equipment. Below is a detailed guide to the installation and maintenance of plum couplings.

4.1 Installation Procedures and Key Considerations

The installation of plum couplings should follow a systematic process, focusing on three core objectives: ensuring precise shaft alignment, protecting the elastic element from damage, and achieving secure fastening of components.

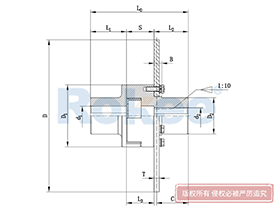

First, pre-installation preparation is critical. Before installation, all components (half-couplings, elastic element, bolts) should be thoroughly cleaned to remove oil, rust, and debris using anhydrous ethanol or acetone. Any burrs on the inner bore of the half-couplings or the shaft surfaces should be removed using fine sandpaper, as burrs can cause abnormal fit gaps and increase vibration during operation. The elastic element should be inspected for cracks, missing lobes, or elastic failure (e.g., failure to rebound after compression). The half-couplings should also be checked for deformation or dimensional deviations using calipers or micrometers.

Next, the half-couplings are mounted on the shafts of the prime mover and working machinery. For interference fits (common in small-sized couplings), the half-coupling can be heated in 80-100℃ hot oil for 5-10 minutes to expand the inner bore, facilitating easy installation without damaging the shaft or coupling. Hammering the half-coupling directly with a steel hammer should be avoided, as this can cause the inner bore to become out of round and affect alignment. For transition fits, a small amount of lubricating grease (e.g., lithium-based grease) can be applied to the mating surfaces to reduce installation resistance. After installation, the half-coupling should be firmly pressed against the shaft shoulder and secured with set screws or locking nuts to prevent axial movement, which can cause friction between the elastic element and the half-coupling faces.

Shaft alignment is the most critical step in the installation process. Although plum couplings can compensate for misalignments, excessive deviations will cause uneven stress on the elastic element, leading to overheating and premature failure. The allowable deviations vary depending on the coupling size, but generally, the radial deviation should not exceed 0.15mm, the angular deviation should not exceed 0.5°, and the axial deviation should not exceed 0.5mm. Precision alignment tools such as dial indicators (for simple applications) or laser alignment systems (for high-precision applications) should be used to measure and adjust the alignment. Adjustments can be made by adding or removing shims under the equipment base to correct angular and radial deviations, or by moving the equipment horizontally to correct radial deviations.

Finally, the elastic element and bolts are installed. The elastic element should be fully inserted into the claw grooves of one half-coupling, and the other half-coupling should be aligned and mated with the elastic element, ensuring that the claws of both half-couplings are properly engaged with the lobes of the elastic element. Misalignment during this step can cause local stress concentration on the elastic element, leading to immediate or premature failure. The bolts should be tightened evenly in a diagonal sequence (e.g., 1→3→2→4 for four-bolt couplings) using a torque wrench to the specified torque value. Over-tightening can cause deformation of the half-couplings and compression of the elastic element, while under-tightening can lead to loose bolts and radial runout during operation.

4.2 Maintenance Practices and Fault Handling

Regular maintenance of plum couplings focuses on monitoring the condition of the elastic element (the most vulnerable component) and ensuring the integrity of the coupling assembly. The following maintenance practices are recommended:

Daily visual inspections should be conducted during operation to check for abnormal noise (e.g., clicking or rattling sounds) and vibration. Abnormal noise or vibration often indicates wear or damage to the elastic element, loose bolts, or misalignment. If such issues are detected, the equipment should be shut down immediately for inspection.

Weekly detailed inspections should include checking the elastic element for signs of wear, aging, or damage. For polyurethane elastic elements, "whitening" of the surface indicates aging, and local indentations indicate compression deformation—both of which require immediate replacement. The bolts should also be checked for tightness using a wrench, and any loose bolts should be re-tightened or replaced if necessary.

Monthly temperature monitoring is recommended using an infrared thermometer. The normal operating temperature of the coupling should not exceed 30℃ above the ambient temperature. Excessive temperature rise may be caused by misalignment, overloading, or friction between components, requiring further investigation and correction.

The elastic element should be replaced periodically based on the operating conditions. In normal operating environments (room temperature, moderate torque, no vibration), the service life of a polyurethane elastic element is typically 6-12 months. In harsh environments (high temperature, high humidity, corrosive substances, or frequent shock loads), the replacement cycle should be shortened to 3-6 months. When replacing the elastic element, the two half-couplings may need to be moved axially to facilitate removal and installation. The new elastic element should have the same material, size, and hardness as the original to ensure consistent performance.

Common faults of plum couplings and their handling methods include:

- Elastic element fracture: This is usually caused by excessive misalignment, overloading, or material aging. The solution is to replace the elastic element and recheck the shaft alignment and torque load.

- Loose bolts: Caused by vibration or insufficient torque during installation. The solution is to re-tighten the bolts using a torque wrench and apply thread locker if necessary.

- Abnormal vibration: Caused by misalignment, worn elastic elements, or deformed half-couplings. The solution is to check and adjust the alignment, replace the elastic element, or repair/replace the deformed half-couplings.

- Overheating: Caused by excessive friction due to misalignment or tight fit. The solution is to adjust the alignment and check the mating surfaces for excessive tightness.

5. Application Scenarios of Plum Couplings

Due to their compact structure, flexible performance, easy maintenance, and cost-effectiveness, plum couplings are widely used in various industrial fields. Their ability to compensate for misalignments and dampen vibrations makes them suitable for applications with frequent starts, forward-reverse operations, and moderate to high speeds. Below are the main application scenarios:

5.1 General Industrial Machinery

Plum couplings are extensively used in general industrial machinery such as pumps, fans, compressors, and conveyors. In these applications, they connect electric motors to the working machinery, compensating for the slight misalignments that may occur during installation or operation. For example, in water treatment plants, plum couplings are used to connect motors to water pumps, ensuring stable water supply by reducing vibration and protecting the pump bearings from additional loads. In HVAC systems, they connect motors to fans, improving the efficiency and reliability of air circulation systems.

5.2 Precision Machinery and Automation Equipment

In precision machinery such as CNC machine tools, machining centers, and engraving machines, plum couplings are used to connect servo motors to ball screws or linear guides. The low moment of inertia and high precision of aluminum alloy plum couplings make them ideal for these applications, as they can transmit torque accurately and respond quickly to control signals. The elastic element also helps dampen the vibrations generated by the servo motor, improving the machining accuracy of the equipment. Additionally, in robotic systems, plum couplings are used in joint drives, ensuring smooth and precise movement of the robot arms.

5.3 Metallurgy, Mining, and Heavy Industry

In metallurgy and mining industries, plum couplings are used in equipment such as crushers, belt conveyors, and rolling mills. These applications involve high torque, frequent starts, and harsh operating conditions (e.g., dust, vibration, and temperature fluctuations). Carbon steel plum couplings with high-strength polyurethane elastic elements are preferred here, as they can withstand heavy loads and resist wear and corrosion. For example, in coal mines, plum couplings connect motors to conveyor belts, ensuring the continuous transportation of coal by compensating for the misalignments caused by the long-distance conveyor structure.

5.4 Light Industry and Textile Industry

In light industry and textile industry, plum couplings are used in equipment such as textile machines, printing machines, and packaging machines. These applications require smooth operation and low noise to ensure product quality. Rubber or soft polyurethane elastic elements are used in these couplings to provide excellent vibration damping and noise reduction. For example, in textile mills, plum couplings connect motors to spinning machines, reducing vibration and ensuring the uniform tension of the yarn, which improves the quality of the finished textile products.

5.5 Automotive and Transportation Equipment

In automotive and transportation equipment, plum couplings are used in auxiliary systems such as power steering pumps, air conditioning compressors, and water pumps. The compact size and lightweight design of aluminum alloy plum couplings make them suitable for automotive applications, where space and weight are critical factors. The elastic element also helps absorb the vibrations generated by the engine, improving the comfort and reliability of the vehicle.

6. Comparison with Other Common Coupling Types

To better understand the advantages and limitations of plum couplings, it is useful to compare them with other common coupling types, such as rigid couplings, diaphragm couplings, and slider couplings.

Rigid couplings are the simplest type of coupling, consisting of two half-couplings connected directly by bolts. They offer high torque transmission capacity and precision but cannot compensate for misalignments or dampen vibrations. Compared to rigid couplings, plum couplings are more flexible, making them suitable for applications where misalignment is inevitable. However, rigid couplings are more suitable for high-precision, low-vibration applications where perfect alignment can be maintained.

Diaphragm couplings use a metal diaphragm to transmit torque and compensate for misalignments. They offer high precision, high torque capacity, and zero backlash, making them suitable for high-speed, high-precision applications such as gas turbines and precision machine tools. Compared to diaphragm couplings, plum couplings are more cost-effective and easier to maintain but have lower transmission precision and torque capacity. Diaphragm couplings are also more resistant to high temperatures than plum couplings, which are limited by the temperature resistance of their elastic elements.

Slider couplings consist of two half-couplings and a sliding block, transmitting torque through the sliding of the block between the half-couplings. They offer high misalignment compensation capacity but have high wear rates and are not suitable for high-speed applications. Compared to slider couplings, plum couplings have lower wear rates, better vibration damping, and higher speed capabilities. However, slider couplings can compensate for larger misalignments than plum couplings, making them suitable for applications with significant shaft offsets.

In summary, plum couplings strike a balance between flexibility, cost-effectiveness, and ease of maintenance, making them the preferred choice for a wide range of industrial applications. Their main limitations are their limited temperature resistance (due to the elastic element) and lower transmission precision compared to diaphragm couplings.

7. Future Development Trends of Plum Couplings

With the continuous advancement of industrial technology, the requirements for power transmission systems are becoming increasingly stringent, driving the development of plum couplings in several key directions:

First, the development of high-performance materials will improve the performance of plum couplings. Researchers are exploring new elastic materials with higher temperature resistance, wear resistance, and fatigue strength, such as composite materials and modified polyurethanes. These materials will extend the service life of the elastic element and expand the application range of plum couplings to high-temperature, high-pressure, and other harsh environments.

Second, the design of plum couplings is becoming more optimized and customized. With the help of computer-aided design (CAD) and finite element analysis (FEA), engineers can optimize the structure of the half-couplings and elastic elements to improve torque capacity, reduce weight, and minimize moment of inertia. Customized designs for specific applications—such as high-speed servo systems, heavy-duty mining equipment, and corrosive chemical environments—will become more common.

Third, the integration of smart monitoring technologies will enhance the reliability of plum couplings. Smart plum couplings equipped with sensors (e.g., temperature sensors, vibration sensors, and strain sensors) will be able to real-time monitor the operating status of the coupling, such as the temperature of the elastic element, vibration amplitude, and torque load. This data can be transmitted to a central control system, enabling predictive maintenance and reducing unplanned downtime.

Fourth, the trend toward lightweight and miniaturization will continue. As industrial equipment becomes more compact and efficient, the demand for lightweight, small-sized plum couplings will increase. The use of lightweight materials such as aluminum alloy and composite materials, combined with optimized structural design, will help reduce the weight and size of plum couplings while maintaining their performance.

8. Conclusion

The plum coupling is a versatile and reliable power transmission component that plays a critical role in modern industrial operations. Its simple yet effective structure, combined with its ability to compensate for misalignments, dampen vibrations, and protect connected equipment, makes it suitable for a wide range of applications across various industries. The selection of appropriate materials, proper installation, and regular maintenance are essential for ensuring the optimal performance and long service life of plum couplings.

As industrial technology continues to evolve, plum couplings will continue to develop in the direction of high performance, customization, smart monitoring, and lightweight design. These advancements will further expand their application range and improve the efficiency and reliability of power transmission systems. Whether in general industrial machinery, precision automation equipment, or heavy-duty mining operations, the plum coupling will remain an indispensable component, contributing to the smooth and efficient operation of industrial processes.

« Plum Couplings » Post Date: 2023/7/3

URL: http://www.rokee.com/en/tags/PlumCouplings.html