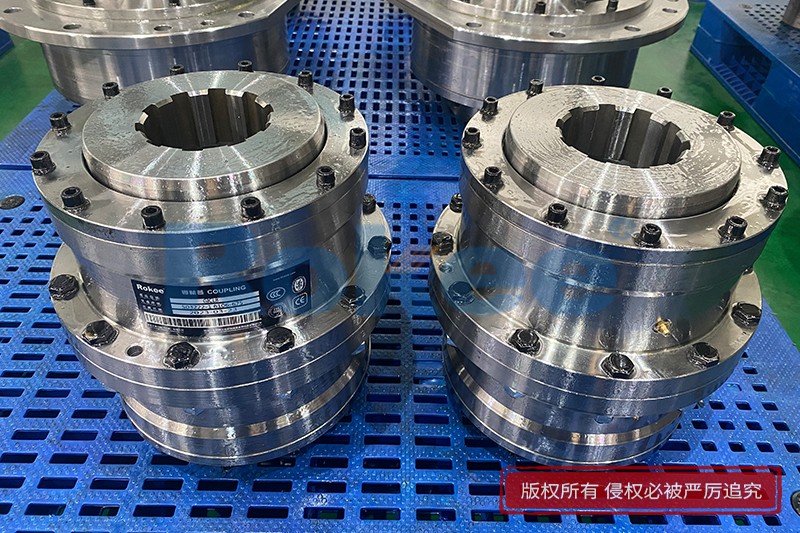

Toothed Couplings

Rokee is Toothed Couplings Manufacturer, Customizable according to the toothed couplings drawings provided by the customer, Support Export.

Toothed Coupling has compact and reasonable structure, light weight, small hole-position fitting draw ratio, large pressure angle design, accurate centering and excellent speed performance. The bolt design has been standardized in series, the universality of parts is good and its service life far exceeds the one of domestic products.

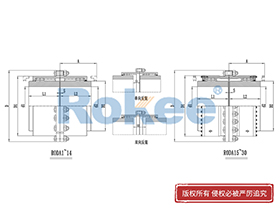

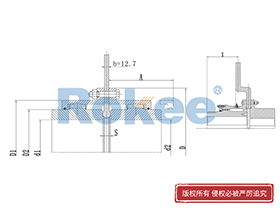

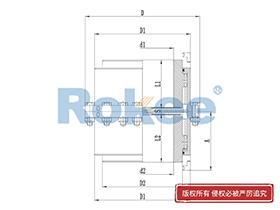

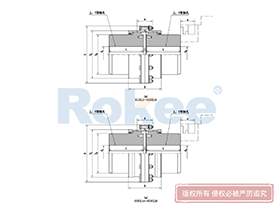

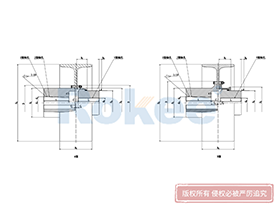

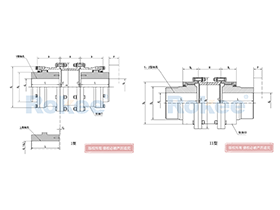

RODA Drum Gear Coupling

Basic Type

The RODA Drum Gear Coupling is the basic type of ROD series coupling, suitable for most situations where the compensation of transmission distance and motion position does not require special increase.View MoreRODT Drum Gear Coupling

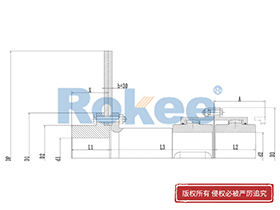

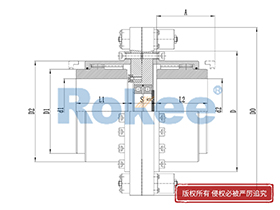

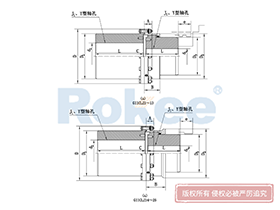

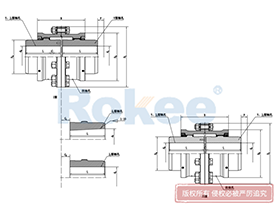

Intermediate Connecting Pipe

The RODT Drum Gear Coupling is an extended type of ROD series coupling, suitable for increasing transmission distance.View MoreRODX Drum Gear Coupling

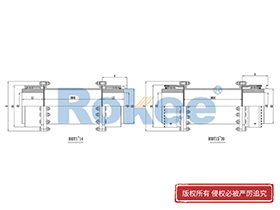

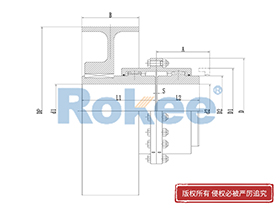

Intermediate Connecting Shaft

RODX Drum Gear Coupling is an extended type of ROD series coupling with a floating shaft design in the middle, suitable for increasing transmission distance.View MoreRODP Drum Gear Coupling

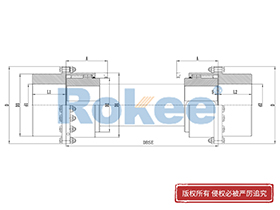

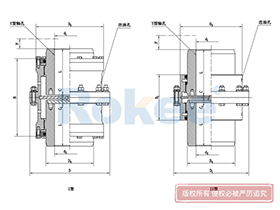

With Brake Discs

The RODP Drum Gear Coupling is a type of ROD series coupling with a brake disc, suitable for transmission situations where braking needs to be used in conjunction with disc brakes.View MoreRODF Drum Gear Coupling

Split Type, Brake Disc

The RODF Drum Gear Coupling is a type of ROD series coupling with split brake discs, suitable for transmission situations where there is braking demand and the braking position changes when used in conjunction with disc brakes.View MoreRODW Drum Gear Coupling

With Brake Wheel

The RODW Drum Gear Coupling is a type of ROD series coupling with brake wheels, suitable for transmission situations where braking needs to be used in conjunction with wheel brakes.View MoreRODU Drum Gear Coupling

With Brake Wheel

The RODU Drum Gear Coupling is another type of ROD series coupling with brake wheels, suitable for transmission situations where braking needs to be used in conjunction with wheel brakes and applied to one end of the axle, achieving smoother and more reliable braking performance.View MoreRODV Drum Gear Coupling

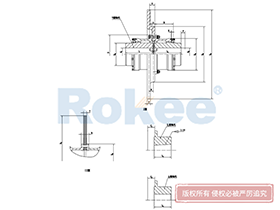

Vertical Installation

The RODV Drum Gear Coupling is a vertical installation type of the ROD series coupling, suitable for transmission situations that require vertical transmission torque.View MoreRODM Drum Gear Coupling

Torsion Protection

The RODM Drum Gear Coupling is a torque setting form of the ROD series coupling. By adjusting relevant components, the maximum transmission torque can be easily set within a certain range. Suitable for shafting transmission situations that require safe torque operation to protect important machine components from excessive damage.View MoreGICL Drum Gear Coupling

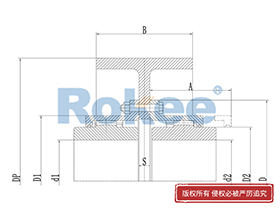

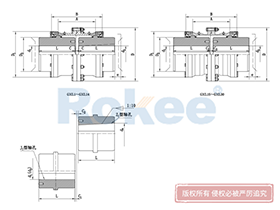

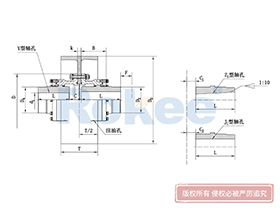

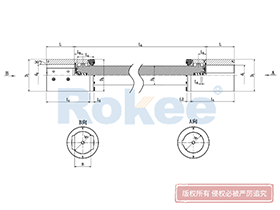

Wide

GICL Drum Gear Coupling has larger inner teeth width, which can transfer torque while compensating for larger axial displacement.View MoreGICLZ Drum Gear Coupling

Connected to Intermediate Shaft

Half of the GICLZ Drum Gear Coupling adopts a non-toothed semi-coupling sleeve structure, which is usually connected in pairs or used in occasions with small angular displacement.View MoreGIICL Drum Gear Coupling

Narrow

GIICL Drum Gear Coupling has small inner teeth width, which can transfer torque while compensating for small axial displacement. Also, its structure is compact and the moment of inertia is low.View MoreGIICLZ Drum Gear Coupling

Connected to Intermediate Shaft

Half of the GIICLZ Drum Gear Coupling adopts a non-toothed semi-coupling sleeve structure, which is usually connected in pairs or used in occasions with small angular displacement. Also, its structure is compact and the moment of inertia is low.View MoreGCLD Drum Gear Coupling

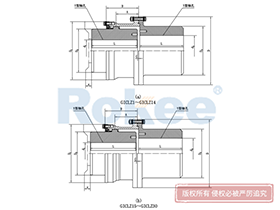

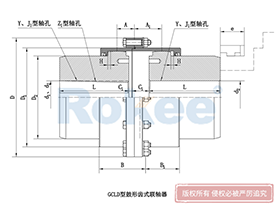

Motor Shaft Extension

GCLD Drum Gear Coupling is generally used for direct connection with the motor, so it generally has a higher speed and compact structure.View MoreNGCL Drum Gear Coupling

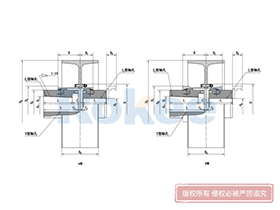

With Brake Wheel

NGCL Drum Gear Coupling is designed with a brake wheel, suitable for situations where braking is required.View MoreNGCLZ Drum Gear Coupling

With Brake Wheel

NGCLZ Drum Gear Coupling is designed with a brake wheel, suitable for situations where braking is required. Half of its structure adopts a semi-coupling sleeve design, with smaller angular displacement compensation but more stable braking.View MoreWG Drum Gear Coupling

Basic

The overall characteristics of WG Drum Gear Coupling are similar to those of other drum gear couplings, but with a larger modulus design, which can generally transmit greater torque.View MoreWGZ Drum Gear Coupling

With Brake Wheel

WGZ Drum Gear Coupling is designed with a brake wheel, suitable for shoe type braking.View MoreWGP Drum Gear Coupling

With Brake Discs

WGP Drum Gear Coupling is designed with a brake disc, suitable for disc type braking.View MoreWGT Drum Gear Coupling

Intermediate Connecting Pipe

WGT Drum Gear Coupling is designed with indirect tube, suitable for long distance torque transfer.View MoreWGC Drum Gear Coupling

Vertical Installation

WGC Drum Gear Coupling is specially designed for situations where vertical transmission is required, suitable for some vertical transmission systems.View MoreWGJ Drum Gear Coupling

Connected to Intermediate Shaft

WGJ Drum Gear Coupling is designed with intermediate shaft, suitable for long distance torque transmission, and some are equipped with axial buffers.View More

In the complex ecosystem of industrial power transmission systems, couplings serve as the critical link between driving and driven shafts, ensuring the smooth transfer of torque while accommodating inevitable misalignments. Among the diverse range of coupling technologies available, toothed couplings stand out for their exceptional torque-carrying capacity, robust performance, and versatility in harsh operating environments. From heavy-duty metallurgical equipment to precision energy systems, toothed couplings play an irreplaceable role in maintaining operational stability and efficiency.

1. Fundamental Structure and Working Principle of Toothed Couplings

At its core, a toothed coupling is a rigid-flexible coupling that achieves power transmission through the meshing of gear teeth. Its basic structure consists of four primary components: external gear sleeves (flange half-couplings with external teeth), internal gear rings, end caps, and sealing devices. The external gear sleeves are typically connected to the driving and driven shafts via keyways, while the internal gear rings mesh with the external gear sleeves to form a torque-transmitting assembly. The end caps and sealing devices serve to protect the internal gear meshing mechanism, prevent lubricant leakage, and block the ingress of external contaminants such as dust, moisture, and debris.

The working principle of toothed couplings is rooted in the meshing characteristics of involute gears. When the driving shaft rotates, torque is transmitted to the external gear sleeve through the key connection. The external teeth of the sleeve then engage with the internal teeth of the gear ring, transferring the torque to the driven shaft and completing the power transmission process. A distinctive feature of toothed couplings is their ability to compensate for shaft misalignments. During operation, when relative displacements occur between the two shafts—including axial (longitudinal), radial (lateral), and angular (tilt) misalignments—the special design of the gear teeth allows for periodic axial sliding between the internal and external tooth surfaces. This sliding motion enables the coupling to adapt to misalignments without generating excessive additional loads, thereby reducing stress concentration on the shafts and bearings and extending the service life of the entire transmission system.

The effectiveness of torque transmission and misalignment compensation in toothed couplings is highly dependent on the precision of gear machining and assembly. The gear teeth are typically manufactured using high-precision processes to ensure smooth meshing. The involute tooth profile, with a standard pressure angle of 20 degrees, is commonly adopted for its superior meshing performance and load-bearing capacity. Additionally, the tooth surface is often subjected to specialized heat treatment and surface strengthening processes to enhance wear resistance and fatigue strength, which are critical for withstanding the harsh conditions of industrial operations.

2. Main Types of Toothed Couplings and Their Performance Differences

Based on the design of the external gear teeth, toothed couplings are primarily classified into two categories: straight-tooth couplings and crowned-tooth (drum-shaped tooth) couplings. These two types differ significantly in structure, performance, and application scenarios, each with its own advantages and limitations.

2.1 Straight-Tooth Couplings

Straight-tooth couplings feature external gear sleeves with linear tooth profiles. This simplistic design makes them relatively easy to manufacture, resulting in lower production costs. The assembly process of straight-tooth couplings is also straightforward, requiring less technical expertise compared to other types. These characteristics make straight-tooth couplings a cost-effective choice for medium and small-power transmission systems where the requirements for misalignment compensation are not overly demanding.

However, the linear tooth profile of straight-tooth couplings imposes significant limitations on their performance. Their ability to compensate for radial and angular misalignments is weak. When the two shafts are misaligned, the contact between the internal and external teeth becomes concentrated at the tooth ends, leading to increased local stress, accelerated tooth wear, and reduced transmission efficiency. Additionally, the meshing of straight teeth tends to generate greater vibration and noise during operation, especially at high speeds, which can affect the stability of the entire equipment. As a result, straight-tooth couplings are typically used in low-speed, light-load applications such as small pumps, fans, and general-purpose machinery.

2.2 Crowned-Tooth Couplings

Crowned-tooth couplings represent an optimized evolution of straight-tooth couplings. The key innovation lies in the spherical drum-shaped design of the external gear teeth, with the center of the spherical surface coinciding with the axis of the gear. This design, combined with an increased tooth side clearance, significantly improves the contact conditions between the internal and external teeth.

Compared to straight-tooth couplings, crowned-tooth couplings offer several distinct advantages. Firstly, their misalignment compensation capability is substantially enhanced. They can accommodate larger angular displacements and radial displacements, effectively avoiding the tooth end edge extrusion problem that plagues straight-tooth couplings under misalignment conditions. Secondly, the spherical tooth profile ensures that the contact area between the teeth is larger and the load distribution is more uniform, which significantly improves the torque-carrying capacity. Tests have shown that under the same radial dimensions, crowned-tooth couplings can transmit 15% to 30% more torque than straight-tooth couplings. Thirdly, the smooth meshing of the crowned teeth reduces vibration and noise during operation, enabling more stable transmission even at higher speeds. Finally, the uniform load distribution also reduces tooth wear, extending the service life of the coupling.

The main disadvantage of crowned-tooth couplings is their higher manufacturing complexity. The processing of the spherical tooth profile requires specialized equipment and precision machining techniques, leading to higher production costs. Additionally, while they can compensate for greater misalignments, their installation still requires careful alignment to ensure optimal performance and avoid premature failure. Despite these limitations, the superior performance of crowned-tooth couplings makes them the preferred choice for high-power, high-speed, and heavy-duty applications, such as metallurgical rolling mills, heavy lifting equipment, wind turbine gearboxes, and gas turbines.

3. Key Performance Advantages of Toothed Couplings

Toothed couplings have maintained a prominent position in the field of industrial transmission due to their unique combination of performance advantages. These advantages make them well-suited for a wide range of demanding operating conditions.

Firstly, toothed couplings exhibit exceptional torque-transmitting capacity. The multi-tooth meshing design allows the load to be distributed across multiple tooth surfaces, enabling a much higher torque transmission per unit volume compared to many other types of couplings. This feature is particularly critical in heavy-duty industrial applications where large amounts of power need to be transmitted efficiently. For example, in metallurgical rolling mills, the torque requirements can be extremely high, and toothed couplings are able to meet these demands reliably.

Secondly, their robust misalignment compensation capability addresses a common challenge in mechanical systems. During equipment installation and operation, factors such as foundation settlement, temperature-induced thermal expansion, and mechanical deformation can lead to shaft misalignments. Toothed couplings, especially crowned-tooth variants, can effectively compensate for axial, radial, and angular misalignments simultaneously, reducing the additional loads on shafts and bearings and preventing premature failures. This capability significantly improves the operational stability and reliability of the transmission system.

Thirdly, toothed couplings offer excellent structural compactness. Through optimized design, modern toothed couplings achieve a small radial footprint while maintaining high load-bearing capacity. This compactness is particularly valuable in applications where installation space is limited, such as in the engine compartments of heavy vehicles or the confined spaces of industrial machinery. The small size also results in a lower moment of inertia, which helps to reduce energy consumption and improve the dynamic response of the system.

Fourthly, toothed couplings demonstrate strong environmental adaptability. By selecting appropriate materials and sealing designs, they can operate reliably in harsh environments such as high temperatures, low temperatures, high humidity, dust, and even mild corrosive conditions. For example, in high-temperature applications such as rotary kilns in the cement industry, toothed couplings can be equipped with high-temperature-resistant lubricants and seals to ensure stable performance. In corrosive environments, surface treatments such as phosphating or nickel plating can be applied to the gear surfaces to enhance corrosion resistance.

Finally, toothed couplings are known for their durability and long service life. The core components, such as the external gear sleeves and internal gear rings, are typically made of high-quality alloy steels that undergo rigorous heat treatment processes. These processes, such as quenching and tempering, carburizing and quenching, enhance the material's strength, toughness, and wear resistance. With proper maintenance, toothed couplings can operate continuously for extended periods, reducing the frequency of replacements and minimizing downtime costs.

4. Typical Applications of Toothed Couplings in Industrial Sectors

The combination of high torque capacity, misalignment compensation, and environmental adaptability makes toothed couplings indispensable in a wide range of industrial sectors. Below are some of their key application areas:

4.1 Metallurgical Industry

The metallurgical industry, including steel and non-ferrous metal production, is one of the primary users of toothed couplings. Equipment such as rolling mills, continuous casting machines, and crushers operate under extreme conditions of high torque, heavy loads, and frequent shock loads. Crowned-tooth couplings are widely used in these applications due to their high torque-transmitting capacity and excellent misalignment compensation. For example, in hot rolling mills, the transmission system must handle enormous torques while accommodating the thermal expansion and contraction of the rolls. Toothed couplings ensure the smooth transmission of power, contributing to the stable operation of the rolling process.

4.2 Energy Sector

In the energy sector, toothed couplings play a critical role in both traditional and renewable energy systems. In thermal power plants and nuclear power plants, they are used in the transmission systems of turbines and generators, where high precision and reliability are essential. In wind energy systems, toothed couplings connect the wind turbine rotor to the gearbox, transmitting the torque generated by the rotor to the generator. The harsh operating environment of wind turbines, including variable wind loads and frequent misalignments due to tower deflection, requires couplings with robust performance and misalignment compensation capabilities. Crowned-tooth couplings are well-suited for these applications, ensuring efficient power transmission and long service life.

4.3 Heavy Machinery and Lifting Equipment

Heavy machinery such as cranes, excavators, and conveyor systems in mining and construction rely on toothed couplings for power transmission. These applications involve heavy loads, frequent starts and stops, and significant misalignments. Toothed couplings provide the necessary torque capacity and flexibility to handle these conditions. For example, in large overhead cranes, the coupling between the motor and the reducer must transmit high torque while accommodating the misalignment caused by the movement of the crane trolley. Toothed couplings ensure the reliable operation of the lifting mechanism, preventing accidents and ensuring operational safety.

4.4 General Machinery and Manufacturing

In general machinery, such as pumps, fans, compressors, and machine tools, toothed couplings are used in medium to large-power transmission systems. For example, in large centrifugal pumps used in water supply and drainage systems, toothed couplings connect the motor to the pump shaft, ensuring efficient torque transmission and compensating for any misalignments between the two shafts. In precision machine tools, such as CNC machining centers, high-precision toothed couplings are used to maintain the accuracy of the transmission system, ensuring the quality of the machined parts.

4.5 Automotive and Transportation Industry

In the automotive and transportation industry, toothed couplings are used in the drivetrains of heavy-duty vehicles, such as trucks, buses, and off-road vehicles. They are also used in the transmission systems of railway locomotives and ships. These applications require couplings that can withstand high torque, shock loads, and harsh environmental conditions. Toothed couplings provide the necessary reliability and durability, ensuring the smooth operation of the vehicle's powertrain.

5. Maintenance and Care of Toothed Couplings

Proper maintenance is essential to ensure the long-term reliable operation of toothed couplings. The key maintenance aspects include lubrication management, installation alignment, condition monitoring, and environmental protection. Neglecting maintenance can lead to accelerated wear, reduced performance, and premature failure of the coupling, resulting in unplanned downtime and increased maintenance costs.

5.1 Lubrication Management

Lubrication is critical for reducing friction and wear between the meshing tooth surfaces, dissipating heat, and preventing corrosion. The selection of the appropriate lubricant depends on the operating conditions, such as temperature, load, and speed. For high-temperature applications, synthetic greases with high temperature resistance, such as polyurea-based greases that can withstand temperatures up to 180°C, are recommended. For heavy-load environments, greases containing extreme pressure additives, such as molybdenum disulfide (MoS₂) or graphite, should be used to prevent tooth surface scuffing and seizure.

The lubrication interval should be determined based on the operating conditions. Under normal operating conditions, lubricant should be replenished every 3 months. In heavy-load or high-temperature environments, the interval should be shortened to 1 to 2 months. To ensure continuous lubrication, automatic lubrication systems, such as single-point lubricators, can be installed. Before replenishing lubricant, the old grease and any contaminants should be thoroughly cleaned to prevent the accumulation of abrasive particles, which can accelerate tooth wear.

5.2 Installation Alignment

Proper alignment during installation is crucial for the performance and service life of toothed couplings. Even though toothed couplings can compensate for misalignments, excessive misalignment can lead to increased tooth wear, vibration, and noise. Laser alignment tools are recommended for precise alignment, with angular misalignment controlled within 0.5° and radial misalignment within 0.1 mm/m. After the equipment has been operating at normal temperature (hot commissioning), the alignment should be rechecked to compensate for any misalignment caused by thermal expansion.

In addition, the axial clearance of the coupling should be properly adjusted. A small axial clearance (0.2 to 0.5 mm) should be reserved to avoid excessive axial pressure caused by thermal expansion. Over-tight assembly can lead to increased friction and wear, reducing the service life of the coupling.

5.3 Condition Monitoring

Regular condition monitoring is essential for early detection of potential faults in toothed couplings. Key monitoring parameters include torque, vibration, and temperature. Torque sensors can be installed to ensure that the operating torque does not exceed 80% of the rated torque, preventing overloading. Vibration analysis should be performed regularly; abnormal high-frequency components (1 to 5 kHz) in the vibration spectrum may indicate tooth surface wear. The surface temperature of the external gear sleeve should also be monitored; if the temperature exceeds 70°C, the equipment should be shut down to check the lubrication status.

5.4 Environmental Protection

Effective sealing and corrosion protection are important for extending the service life of toothed couplings in harsh environments. Multi-layer labyrinth seals combined with fluororubber lip seals can be used to achieve an IP67 protection rating, effectively preventing the ingress of dust and water. For corrosive environments, surface treatments such as phosphating or nickel plating can be applied to the tooth surfaces, providing salt spray resistance for more than 500 hours.

6. Future Development Trends of Toothed Couplings

With the continuous advancement of industrial technology, the requirements for power transmission systems are becoming increasingly stringent. Toothed couplings are also evolving in response to these demands, with several key development trends emerging.

Firstly, there is a growing focus on material innovation. Traditional alloy steels are being supplemented by advanced materials to improve performance in extreme conditions. For example, spraying ceramic coatings (such as Al₂O₃) on the surface of 42CrMo steel can double the wear resistance of the tooth surfaces. The development and application of high-temperature alloys are also enabling toothed couplings to operate reliably in higher temperature environments, meeting the needs of advanced industrial processes such as ultra-high-temperature heat treatment and power generation.

Secondly, surface treatment technologies are continuously advancing. Advanced surface strengthening processes, such as carburizing and quenching combined with shot peening, are being used to improve the surface hardness and fatigue strength of the tooth surfaces, with surface hardness reaching HRC 60 to 62. The application of diamond-like carbon (DLC) coatings is also increasing; these coatings reduce the friction coefficient by 50% to 70%, significantly reducing tooth wear and power loss.

Thirdly, the integration of intelligent technologies is transforming the maintenance and management of toothed couplings. The incorporation of sensors for real-time monitoring of torque, vibration, temperature, and lubricant condition enables predictive maintenance. By analyzing the collected data, potential faults can be identified and addressed before they lead to unplanned downtime. This intelligent monitoring not only improves the reliability of the coupling but also optimizes maintenance schedules, reducing maintenance costs.

Fourthly, there is a trend towards lightweight and compact design. With the increasing demand for energy efficiency and space optimization, manufacturers are using advanced design tools such as finite element analysis (FEA) to optimize the structure of toothed couplings. This allows for a reduction in weight and size while maintaining or improving torque-carrying capacity, making them more suitable for applications with strict space and weight constraints.

Finally, the development of customized solutions is becoming more prevalent. Different industrial applications have unique requirements for torque, speed, misalignment, and environment. Manufacturers are increasingly offering customized toothed coupling designs to meet these specific needs, improving the compatibility and performance of the coupling with the overall system.

7. Conclusion

Toothed couplings are essential components in industrial power transmission systems, offering exceptional torque-carrying capacity, robust misalignment compensation, and reliable performance in harsh environments. Their unique structure and working principle make them suitable for a wide range of applications across metallurgy, energy, heavy machinery, and other key industries. By understanding the different types of toothed couplings, their performance characteristics, and implementing proper maintenance practices, industrial operators can ensure the long-term reliable operation of their transmission systems.

As industrial technology continues to advance, toothed couplings are evolving through material innovation, advanced surface treatments, intelligent monitoring, and customized design. These developments will further enhance their performance, expand their application scope, and contribute to the efficiency and reliability of future industrial transmission systems. Whether in traditional heavy industry or emerging renewable energy sectors, toothed couplings will remain a critical link in power transmission, supporting the sustainable development of global industry.

« Toothed Couplings » Post Date: 2023/10/9

URL: http://www.rokee.com/en/tags/toothed-couplings.html