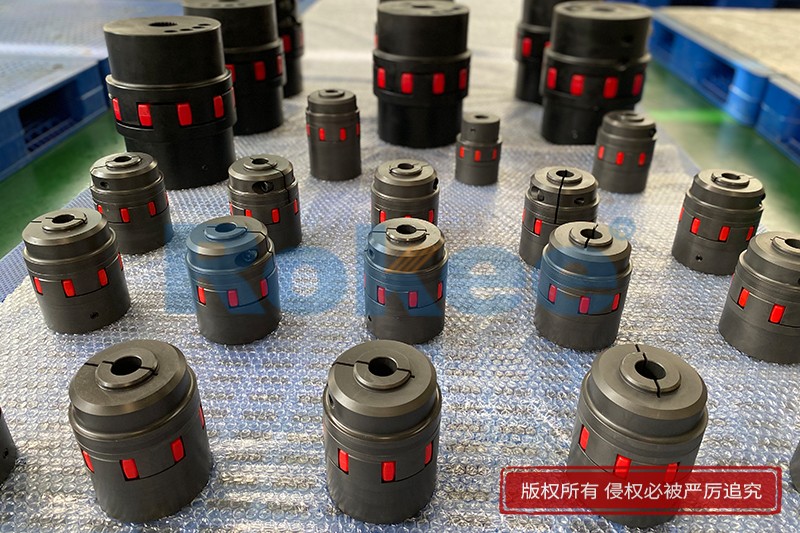

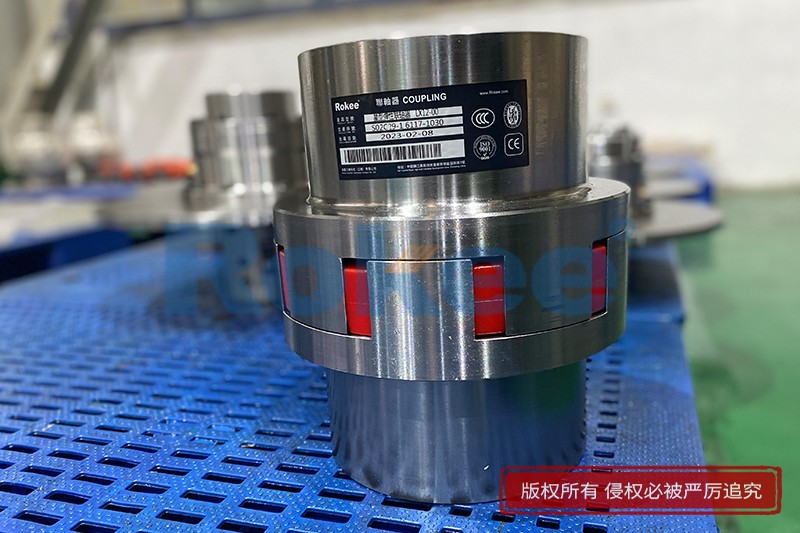

Star Couplings

Rokee is Star Couplings Manufacturer, Customizable according to the star couplings drawings provided by the customer, Support Export.

Star Coupling is an elastic component made of engineering plastic, suitable for connecting two coaxial transmission shaft systems. It has compensation for relative deviation between two shafts, buffering, shock absorption, and wear resistance. It is widely used in various occasions, with a transmission torque of 20-35000 N.M and a working temperature of -35-+80 degrees Celsius. Polyurethane elastomers are limited by convex claw blocks.

In the field of mechanical transmission and optical communication systems, coupling devices play an indispensable role in ensuring efficient energy transfer, signal transmission, and system stability. Among various coupling types, the star coupling stands out due to its unique structural design and versatile performance characteristics. Widely applied in industrial machinery, automation equipment, fiber optic networks, and renewable energy systems, star couplings have become a critical component supporting the operation of modern industrial chains and communication infrastructures.

1. Definition and Classification of Star Coupling

A star coupling is a type of coupling device designed to transmit torque, power, or signals between multiple components or terminals, characterized by a radial or star-shaped structural layout. Unlike traditional linear or T-shaped couplings, star couplings typically feature a central connection point with multiple output branches, enabling one-to-many or many-to-many transmission. Based on their application fields and functional characteristics, star couplings can be broadly classified into two major categories: mechanical star couplings and optical star couplers.

Mechanical star couplings, also known as star-shaped flexible couplings or spider couplings, are primarily used in mechanical transmission systems to connect two or more rotating shafts. Their core function is to transmit torque while compensating for misalignments between shafts, reducing vibration, and buffering shocks. Optical star couplers, on the other hand, are passive optical devices widely used in fiber optic communication networks. They are designed to distribute optical signals from one input port to multiple output ports or combine signals from multiple input ports into one output port, realizing efficient signal distribution in multi-terminal communication systems.

2. Structural Composition and Working Principles

2.1 Mechanical Star Couplings: Structure and Working Mechanism

Mechanical star couplings consist of three core components: two hubs (claw plates) and a star-shaped flexible element (often referred to as a spider). The hubs are typically made of high-strength metallic materials such as aluminum alloy, carbon steel, or stainless steel, which provide sufficient structural rigidity to withstand torque loads. The star-shaped flexible element is usually fabricated from elastomeric materials like polyurethane or rubber, which possess excellent elasticity and wear resistance.

The working principle of mechanical star couplings is based on the elastic deformation of the star-shaped element. When torque is transmitted from the driving shaft to one hub, the hub exerts a force on the star-shaped flexible element. The elastic element then deforms and transfers the torque to the other hub, which drives the driven shaft to rotate. During this process, the flexible element plays a crucial role in compensating for misalignments between the two shafts, including angular misalignment, parallel misalignment, and axial displacement. The elastic deformation of the spider allows for small deviations between the shafts without causing excessive stress on the coupling or the connected equipment. Additionally, the elastomeric material of the flexible element exhibits good damping properties, which can absorb shocks and vibrations generated during the operation of the machinery, reducing noise and extending the service life of the entire transmission system.

The installation of mechanical star couplings is relatively straightforward. Most models use set screws or clamping mechanisms to secure the hubs to the shafts, eliminating the need for complex assembly processes. This simplicity in installation and maintenance makes mechanical star couplings a popular choice in various industrial applications.

2.2 Optical Star Couplers: Structure and Signal Transmission Principle

Optical star couplers have a fundamentally different structure and working principle compared to their mechanical counterparts, as they operate based on optical diffraction and waveguiding principles. A typical planar optical star coupler consists of input waveguides, a free propagation region (FPR), and output waveguide arrays. The input waveguides are responsible for guiding the optical signal into the coupler, while the free propagation region allows the light beam to diverge due to diffraction. The output waveguide array then collects the divergent light and guides it to the respective output ports.

The key to the operation of optical star couplers lies in the transformation of the waveguide mode into a divergent Gaussian beam in the free propagation region. For conventional waveguides with a V-parameter (a dimensionless parameter describing waveguide properties) in the range of 2 to 5, the waveguide mode closely resembles a Gaussian beam. This allows the divergent beam in the free propagation region to be accurately approximated as a Gaussian beam, which ensures efficient coupling to the output waveguide array. If the design is optimized, the transition from the input waveguide to the free propagation region and then to the output waveguides can be nearly lossless, resulting in low insertion loss.

In fiber optic communication systems, optical star couplers function as passive devices, meaning they do not require external power to operate. When an optical signal is introduced into any input port, it is distributed to all output ports uniformly (or in a predetermined ratio). The number of ports in optical star couplers is typically a power of 2 (e.g., 2×2, 4×4, 8×8), which facilitates the construction of large-scale communication networks. In multi-terminal systems with 20 or more terminals, optical star couplers outperform T-shaped couplers due to their superior power distribution characteristics. Unlike serial systems using T-couplers, where the optical power decreases as the signal travels through more couplers, parallel systems using star couplers maintain consistent power distribution between any pair of terminals, resulting in lower overall system loss.

3. Key Performance Indicators of Star Couplings

The performance of star couplings is evaluated based on a set of critical indicators that vary slightly between mechanical and optical types. Understanding these indicators is essential for selecting the appropriate coupling for specific applications.

3.1 Performance Indicators for Mechanical Star Couplings

1. Torque Transmission Capacity: This refers to the maximum torque that the coupling can transmit without failure. The torque capacity of mechanical star couplings ranges from 20 N·m to 2500 N·m, depending on the size of the coupling, the material of the hubs, and the properties of the flexible element. Couplings with higher torque capacities are suitable for medium to high-power transmission systems such as compressors, generators, and heavy machinery.

2. Misalignment Compensation Range: This indicator measures the maximum amount of misalignment (angular, parallel, axial) that the coupling can accommodate. Typically, mechanical star couplings can compensate for angular misalignment up to 1.5° to 3°, parallel misalignment up to 0.1 mm to 0.5 mm, and axial displacement up to 2 mm to 5 mm. Exceeding these ranges can lead to premature wear of the flexible element and reduced coupling lifespan.

3. Operating Temperature Range: The operating temperature range is determined by the material of the flexible element. Most elastomeric spider elements can withstand temperatures between -35°C and 80°C, making them suitable for normal industrial environments. For applications in extreme temperature conditions (e.g., high-temperature furnaces or low-temperature refrigeration systems), specialized high-temperature or low-temperature resistant materials may be required.

4. Allowable Speed: This is the maximum rotational speed at which the coupling can operate stably without generating excessive centrifugal force. Mechanical star couplings typically have an allowable speed ranging from 1800 rpm to 19,000 rpm, depending on the material and structural design. High-speed applications such as machine tool spindles require couplings with higher allowable speeds to ensure stable operation.

5. Damping and Vibration Reduction Performance: The ability of the coupling to absorb shocks and vibrations is critical for protecting the connected machinery. The elastomeric flexible element of mechanical star couplings provides effective damping, reducing the impact of load fluctuations and equipment imbalance on the transmission system.

3.2 Performance Indicators for Optical Star Couplers

1. Insertion Loss: Insertion loss is the amount of optical power lost as the signal passes through the coupler. It is a key indicator of the coupler's efficiency. Well-designed optical star couplers can achieve insertion loss of less than 1 dB, which is crucial for maintaining signal strength in long-distance communication systems. The main sources of insertion loss include diffraction losses in the free propagation region and coupling losses between the waveguides and the free propagation region.

2. Coupling Uniformity: This refers to the consistency of the optical power distribution among the output ports. For most applications, uniform power distribution is desirable to ensure that all receiving terminals receive signals of equal strength. The mode of the input light (typically Gaussian) can affect coupling uniformity. In some cases, tapering the width of the output waveguides towards the edges of the array can help improve uniformity, although this correction is limited.

3. Side Lobe Level: The side lobe level is a measure of the unwanted signal components generated during the coupling process. A low side lobe level is essential for reducing signal interference in optical communication systems. The Gaussian distribution of the light beam in the free propagation region of optical star couplers helps produce a low side lobe level, making them suitable for use in optical phased arrays and arrayed waveguide gratings.

4. Port Count: The number of input and output ports (port count) determines the scalability of the optical star coupler in large-scale networks. As mentioned earlier, the port count is usually a power of 2, with 8×8 and 16×16 couplers being common in practical applications. Higher port counts allow for more terminals to be connected to the network, increasing the system's capacity.

4. Applications of Star Couplings Across Industries

The versatility of star couplings makes them applicable in a wide range of industries, from traditional manufacturing to advanced telecommunications and renewable energy. The following sections detail the key applications of mechanical and optical star couplers.

4.1 Mechanical Star Couplings: Industrial Applications

1. Industrial Automation and Robotics: In automated production lines and robotic systems, mechanical star couplings are used to connect motors, reducers, and robotic arms. The precise torque transmission and misalignment compensation capabilities of these couplings ensure the smooth and accurate operation of robotic movements. For example, in assembly line robots, star couplings help maintain the precision of pick-and-place operations by reducing vibrations and compensating for minor shaft misalignments.

2. Manufacturing Machinery: Mechanical star couplings are widely used in various manufacturing equipment, including machine tools, conveyors, and pumps. In machine tools (e.g., lathes, milling machines), they transmit torque from the motor to the spindle, ensuring stable high-speed rotation and precise machining. In conveyor systems, star couplings connect the drive motor to the conveyor belt, accommodating misalignments caused by the long span of the conveyor and reducing wear on the motor and bearings.

3. Renewable Energy Systems: The renewable energy sector, particularly wind and solar power, relies heavily on mechanical star couplings. In wind turbines, star couplings are used in the transmission system to connect the rotor to the generator. They compensate for misalignments caused by wind-induced vibrations and buffer the impact of variable wind loads, protecting the generator and extending its service life. In solar tracking systems, star couplings enable precise rotation of the solar panels to follow the sun, ensuring maximum energy absorption.

4. Automotive and Transportation: In the automotive industry, mechanical star couplings are used in the transmission systems of both traditional and electric vehicles. They connect the engine (or motor) to the gearbox, transmitting torque while compensating for misalignments between the components. The damping properties of the couplings also help reduce noise and vibration in the vehicle, improving ride comfort. Additionally, in railway systems, star couplings are used in the drive systems of trains and trams, accommodating the dynamic misalignments caused by track irregularities.

5. Chemical and Pharmaceutical Industry: In chemical processing plants, mechanical star couplings are used in pumps, mixers, and agitators. The corrosion-resistant materials used in the hubs (e.g., stainless steel) make them suitable for harsh chemical environments. The couplings' ability to reduce vibration also ensures the stable operation of equipment handling hazardous or volatile materials, minimizing the risk of leaks.

4.2 Optical Star Couplers: Communication and Data Transmission Applications

1. Fiber Optic Communication Networks: Optical star couplers are a core component of passive optical networks (PONs), which are widely used in broadband access systems. In PONs, a single optical line terminal (OLT) connects to multiple optical network units (ONUs) via an optical star coupler, enabling the distribution of high-speed internet signals to multiple households or businesses. This one-to-many distribution model reduces the cost of network infrastructure by minimizing the number of fiber optic cables required.

2. Data Centers and High-Speed Computing: Data centers require high-speed, reliable data transmission between servers and storage devices. Optical star couplers facilitate the construction of parallel optical communication networks, enabling simultaneous data transmission between multiple servers. Their low insertion loss and uniform power distribution ensure that data signals remain strong and consistent, supporting the high bandwidth requirements of modern data centers.

3. Optical Sensing Systems: Optical star couplers are used in various optical sensing applications, such as environmental monitoring and industrial sensing. In a distributed optical sensing system, the coupler distributes the optical signal to multiple sensors placed at different locations. The reflected signals from the sensors are then combined by the coupler and transmitted back to the detection unit, enabling real-time monitoring of parameters such as temperature, pressure, and strain over a large area.

4. Aerospace and Defense: In aerospace and defense applications, optical star couplers are used in avionics communication systems and radar systems. Their lightweight, compact design and resistance to electromagnetic interference (EMI) make them ideal for use in aircraft and spacecraft. Optical star couplers enable secure, high-speed data transmission between different avionics components, ensuring the reliable operation of critical systems.

5. Current Challenges and Future Development Trends

Despite their widespread use and proven performance, star couplings face several challenges that drive ongoing research and development. These challenges include improving performance under extreme conditions, enhancing scalability, and reducing costs. Looking ahead, several key trends are expected to shape the future of star coupling technology.

5.1 Mechanical Star Couplings: Trends in Material and Design Innovation

One of the main challenges for mechanical star couplings is improving their performance in extreme environments, such as high temperatures, high pressures, and corrosive conditions. To address this, researchers are exploring the use of advanced materials for both the hubs and the flexible elements. For example, the development of high-temperature resistant elastomers (e.g., silicone-based materials) allows mechanical star couplings to operate in temperatures exceeding 150°C, expanding their application in high-temperature industrial processes such as metal smelting.

Another trend is the miniaturization and lightweight design of mechanical star couplings. With the growing demand for compact equipment in industries such as robotics and aerospace, there is a need for smaller, lighter couplings that can still transmit high torque. The use of lightweight metallic alloys (e.g., titanium alloys) and composite materials is helping to reduce the weight of the hubs without compromising their strength. Additionally, 3D printing technology is being used to fabricate complex star-shaped flexible elements with optimized damping properties, allowing for customized designs tailored to specific applications.

The integration of smart monitoring capabilities is also an emerging trend in mechanical star couplings. By embedding sensors (e.g., strain sensors, temperature sensors) into the coupling components, manufacturers can enable real-time monitoring of the coupling's operating status. This allows for predictive maintenance, as potential issues such as excessive wear or misalignment can be detected early, reducing downtime and maintenance costs.

5.2 Optical Star Couplers: Advances in Integration and Performance

For optical star couplers, the main challenges include reducing insertion loss, improving coupling uniformity, and increasing the port count while maintaining a compact footprint. Recent advances in planar lightwave circuit (PLC) technology have enabled the fabrication of highly integrated optical star couplers with lower insertion loss and higher port counts. For example, the development of horn structures in planar star couplers has been shown to significantly reduce packing fraction loss, improving the efficiency of light coupling into the output waveguide array.

Another key trend is the integration of optical star couplers with other optical components, such as wavelength division multiplexers (WDMs) and optical switches. This integration enables the development of more complex and versatile optical communication systems that can handle multiple wavelengths and support dynamic signal routing. For example, in 5G and beyond communication networks, integrated optical star couplers play a crucial role in enabling high-speed, low-latency data transmission.

The development of silicon photonics technology is also driving innovation in optical star couplers. Silicon photonics allows for the fabrication of optical components on silicon wafers, leveraging the mature semiconductor manufacturing infrastructure to reduce costs and increase scalability. Silicon-based optical star couplers offer high integration density and compatibility with electronic components, making them ideal for use in data centers and high-performance computing systems.

6. Conclusion

Star couplings, whether mechanical or optical, are essential components in modern industrial and communication systems. Mechanical star couplings excel in torque transmission, misalignment compensation, and vibration damping, supporting the reliable operation of machinery across industries such as manufacturing, renewable energy, and automotive. Optical star couplers, on the other hand, enable efficient signal distribution in fiber optic networks, playing a critical role in broadband access, data centers, and optical sensing.

The performance of star couplings is defined by key indicators such as torque capacity (mechanical) and insertion loss (optical), which guide their selection for specific applications. Despite facing challenges in extreme environment operation and scalability, ongoing advances in materials, design, and fabrication technologies are driving the evolution of star coupling technology. Future trends such as miniaturization, smart monitoring (mechanical), and integration with other optical components (optical) are expected to expand their application scope and enhance their performance.

As industries continue to pursue higher efficiency, reliability, and connectivity, the importance of star couplings will only grow. By understanding their principles, performances, and applications, engineers and researchers can continue to innovate and optimize star coupling designs, ensuring that they meet the evolving needs of modern technology and industry.

« Star Couplings » Post Date: 2023/7/3

URL: http://www.rokee.com/en/tags/StarCouplings.html