Safety Couplings

Rokee is Safety Couplings Manufacturer, Customizable according to the safety couplings drawings provided by the customer, Support Export.

Rokee's safety couplings are specially designed for overload protection in the heavy-duty industry. If a pre-defined torque limit value is exceeded, the coupling halves and thus the input and output sides are separated quickly and reliably. Typical areas of application are, in particular, building and construction machinery, e.g. excavators, crushers, shredders and grading and tunnel boring machines, as well as rolling mills and steel plants, turbines and industrial conveyor systems.

In the intricate web of modern mechanical systems, where power transmission is the lifeblood of industrial operations, the role of protective components often goes unnoticed until a critical failure occurs. Among these unsung heroes, safety couplings stand out as indispensable guardians, bridging the gap between power generation and load application while safeguarding expensive equipment and ensuring operational continuity. As industrial automation intensifies and machinery becomes increasingly complex, the demand for reliable, efficient, and adaptable safety couplings has never been higher.

1. Defining Safety Couplings: Beyond Basic Power Transmission

At its core, a safety coupling is a mechanical component designed to connect a driving machine (such as an electric motor or engine) to a driven machine (including pumps, conveyors, or gearboxes) for the purpose of transmitting motion and torque. What distinguishes it from standard couplings, however, is its integrated protective function: when the torque in the transmission system exceeds a preset threshold, the safety coupling automatically interrupts or limits power transmission, thereby preventing damage to key equipment and avoiding potential safety hazards. This "mechanical fuse" capability makes safety couplings a critical line of defense against overloads, jams, stalls, and sudden operational failures that could otherwise lead to costly downtime, extensive repairs, or even workplace accidents.

Unlike conventional couplings, which prioritize torque transmission efficiency and alignment compensation, safety couplings balance these functions with proactive protection. After the abnormal operating conditions are resolved, many types of safety couplings can be re-engaged either automatically or manually, allowing production to resume quickly without the need for complex disassembly or replacement of major components. This combination of transmission and protection has made safety couplings a staple in industries ranging from manufacturing and mining to renewable energy and transportation.

2. Core Working Principles: How Safety Couplings Protect Systems

The protective functionality of safety couplings is rooted in three primary working mechanisms: frictional slippage, mechanical separation, and magnetic disengagement. Each mechanism operates on distinct physical principles, making them suitable for different operational requirements and load conditions. Understanding these mechanisms is essential for selecting the right safety coupling for a specific application.

2.1 Frictional Slippage Mechanism

Frictional safety couplings rely on the frictional force between mating components (typically friction plates or blocks) to transmit torque. During normal operation, the friction force—precisely set by adjusting spring pressure or the number of friction plates—ensures that the driving and driven shafts rotate synchronously. When the system torque exceeds the preset limit, the frictional force is overcome, causing relative sliding between the friction plates. This slippage interrupts the direct transmission of excessive torque, effectively protecting the motor, gearbox, and other critical components from damage.

A key advantage of the frictional mechanism is its ability to provide continuous protection without permanent damage to the coupling itself. Once the overload is removed, the friction plates re-engage automatically, allowing the system to resume normal operation immediately. This makes frictional safety couplings ideal for applications with frequent start-stop cycles or intermittent overload risks, such as packaging machinery, textile equipment, and small to medium-sized conveyors.

2.2 Mechanical Separation Mechanism

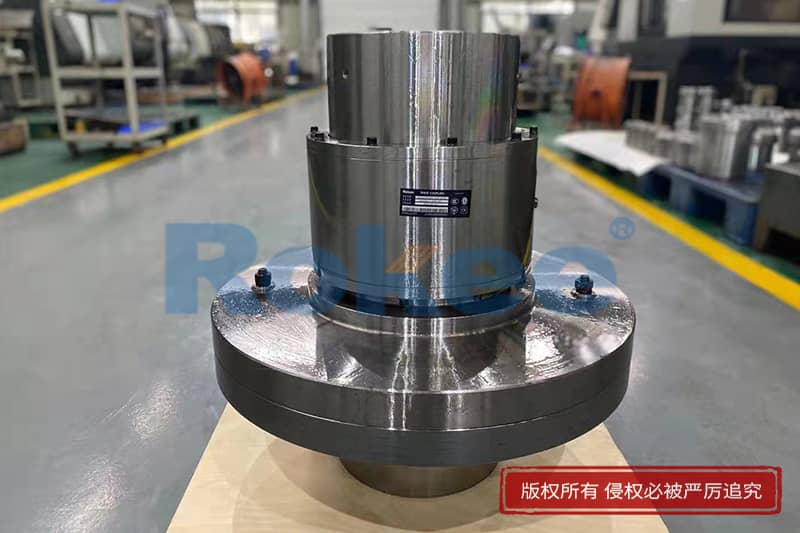

Mechanical safety couplings achieve overload protection through the controlled failure or disengagement of a specific component. The most common designs include shear pin, shear bolt, and ball-engagement types. In shear pin couplings, a precisely calibrated pin connects the driving and driven halves of the coupling. When the torque exceeds the threshold, the shear pin breaks, separating the two halves and cutting off power transmission.

Ball-engagement safety couplings, by contrast, use spring-loaded balls that fit into matching recesses in the coupling halves. Under normal torque conditions, the balls remain seated, ensuring rigid, backlash-free transmission. When overload occurs, the excessive force pushes the balls out of their recesses, disengaging the drive line within milliseconds. Unlike shear pin designs, ball-engagement couplings can be re-engaged without replacing components, simply by resetting the spring-loaded balls.

Mechanical separation mechanisms are known for their high precision and reliability, making them suitable for heavy-duty applications such as steel mills, crushers, and excavators, where sudden torque spikes can cause catastrophic damage. Shear pin designs are particularly cost-effective for low-to-medium torque applications, while ball-engagement couplings are preferred for high-precision systems like servo drives and machine tool spindles.

2.3 Magnetic Disengagement Mechanism

Magnetic safety couplings utilize the attractive force between permanent magnets or electromagnets to transmit torque. The coupling consists of two main parts: a driving rotor with magnets and a driven rotor with a ferromagnetic plate or another set of magnets. During normal operation, the magnetic force keeps the two rotors aligned and rotating synchronously. When the torque exceeds the preset limit, the magnetic force is overcome, and the rotors slip relative to each other, interrupting torque transmission.

One of the key benefits of magnetic safety couplings is their non-contact operation, which eliminates wear and tear on moving parts, reduces maintenance requirements, and enables operation in harsh environments (such as high temperatures, corrosive atmospheres, or cleanrooms). They also offer smooth torque transmission and can be integrated with sensors to provide real-time torque monitoring. Magnetic safety couplings are commonly used in food processing equipment, pharmaceutical machinery, and applications where contamination must be avoided.

3. Classification of Safety Couplings: Types and Their Characteristics

Safety couplings can be classified into various types based on their working mechanisms, structural designs, and application scenarios. Each type has unique advantages and limitations, making them suitable for specific operational conditions. Below is an overview of the most common types and their key characteristics.

3.1 Frictional Type Safety Couplings

As the most widely used type of safety coupling, frictional couplings are valued for their simplicity, adjustability, and low maintenance requirements. They are available in two main sub-types: dry friction (using friction plates made of metal or composite materials) and wet friction (operating in oil or grease for reduced wear). Dry friction couplings are suitable for general industrial applications, while wet friction couplings are preferred for high-torque, high-speed applications such as automotive transmissions and large-scale conveyors.

Key characteristics of frictional safety couplings include stepless adjustment of the slip torque, automatic re-engagement after overload, and compatibility with a wide range of shaft diameters. They are relatively compact and can accommodate minor shaft misalignments, making them versatile for small to medium-sized equipment.

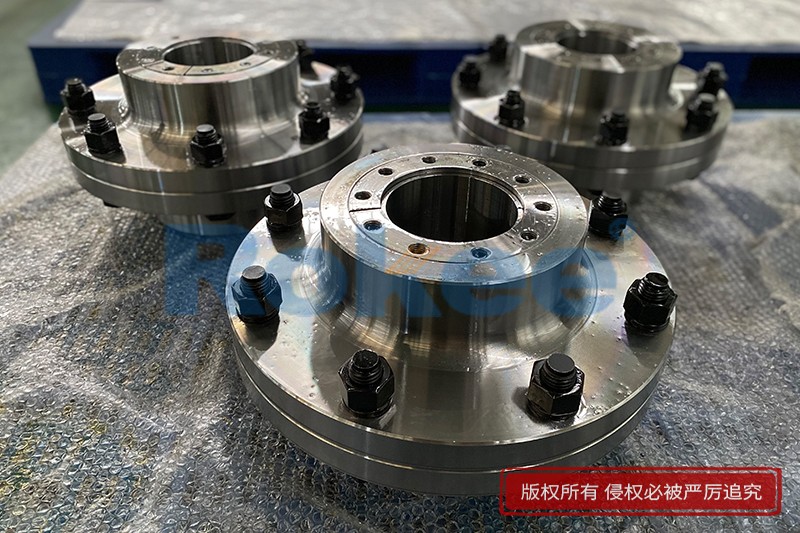

3.2 Shear Pin/Bolt Safety Couplings

Shear pin safety couplings are among the simplest and most cost-effective protective couplings. They consist of two flanges connected by one or more shear pins, which are designed to break at a specific torque value. The torque threshold is determined by the diameter, material, and number of shear pins. Once the pin breaks, the driving flange continues to rotate while the driven flange stops, preventing further torque transmission.

These couplings are ideal for applications where overloads are infrequent and cost is a primary concern, such as agricultural machinery, small pumps, and fans. However, their main limitation is the need to replace the shear pin after each overload, which can result in longer downtime compared to other types. Shear bolt couplings, a variation of this design, use bolts instead of pins and offer higher torque capacity, making them suitable for heavy-duty applications like mining equipment.

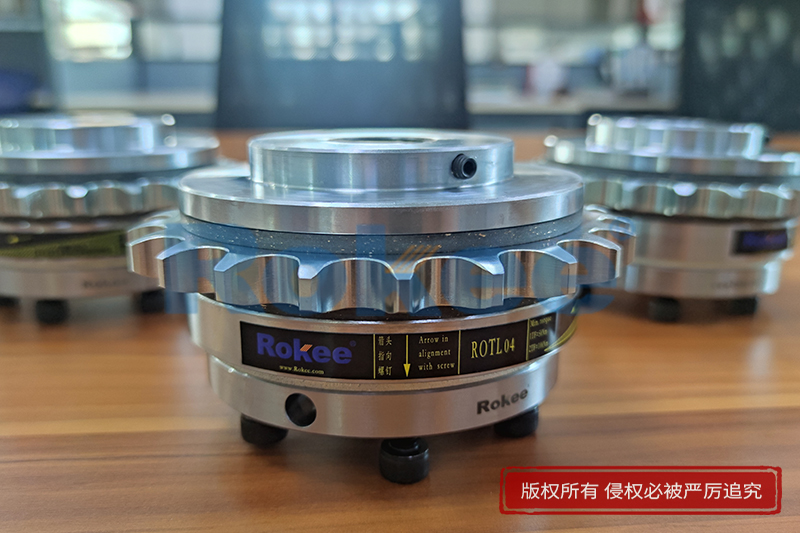

3.3 Ball-Engagement Safety Couplings

Ball-engagement safety couplings are designed for high-precision, backlash-free transmission, making them essential for servo drives, machine tools, and other systems requiring accurate motion control. They use spring-loaded balls that engage with precision-machined recesses in the coupling halves, ensuring rigid torque transmission during normal operation. When overload occurs, the balls are pushed out of the recesses, disengagement the drive line within 1-3 milliseconds.

Key features of ball-engagement couplings include high torsional stiffness, precise torque setting, and quick re-engagement. They are available in both synchronous and ratchet-type designs: synchronous designs re-engage at the same angular position, while ratchet-type designs allow re-engagement at any position. These couplings are particularly suitable for high-speed applications and systems with frequent start-stop cycles.

3.4 Magnetic Safety Couplings

Magnetic safety couplings are divided into permanent magnetic and electromagnetic sub-types. Permanent magnetic couplings use high-strength neodymium magnets to transmit torque, while electromagnetic couplings use an electric current to generate the magnetic field, allowing for adjustable torque settings and remote control. Both types offer non-contact operation, eliminating wear and reducing maintenance.

Permanent magnetic couplings are suitable for fixed-torque applications, while electromagnetic couplings are ideal for systems requiring variable torque settings or automated control. They are widely used in clean environments, corrosive atmospheres, and applications where shaft isolation is necessary (such as seal-less pumps to prevent fluid leakage).

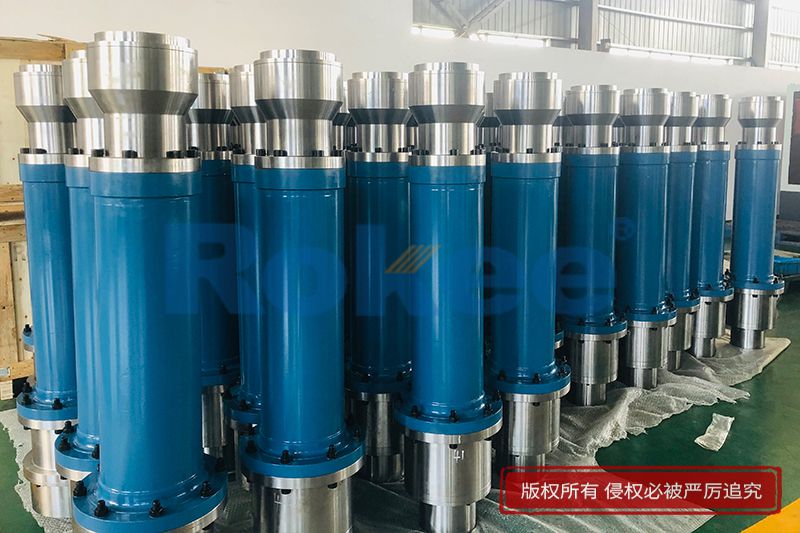

3.5 Hydraulic Safety Couplings

Hydraulic safety couplings use pressure oil as the torque transmission medium. They consist of a coupling sleeve, shear ring, and safety tube. During normal operation, the pressure oil keeps the coupling engaged, transmitting torque through the shear ring. When the torque exceeds the preset limit, the shear ring breaks, releasing the pressure oil and disengagement the drive line. These couplings offer high torque capacity and smooth torque transmission, making them suitable for large-scale equipment such as gas turbines, marine propulsion systems, and heavy-duty conveyors.

Hydraulic safety couplings are known for their ability to handle sudden torque spikes and accommodate large shaft misalignments. They require regular maintenance to ensure proper oil pressure and seal integrity, but their high reliability makes them a preferred choice for critical applications where downtime must be minimized.

4. Applications of Safety Couplings: Across Industries and Systems

The versatility and protective capabilities of safety couplings make them indispensable across a wide range of industries and applications. From small-scale manufacturing equipment to large-scale renewable energy systems, safety couplings play a critical role in ensuring operational safety and efficiency. Below are some of the key application areas.

4.1 Manufacturing and Automation

In manufacturing and automation, safety couplings are used in a variety of equipment, including conveyors, packaging machines, textile machines, and machine tools. Conveyors, which are essential for material handling in factories and warehouses, are prone to overloads caused by jammed materials or broken belts. Safety couplings prevent damage to the conveyor motor and gearbox by interrupting power transmission when such overloads occur.

Machine tools, such as lathes, milling machines, and machining centers, require precise motion control and backlash-free transmission. Ball-engagement safety couplings are commonly used in these applications to protect the spindle and servo drives from damage caused by tool breakage or workpiece jams. Packaging machines, which operate at high speeds with frequent start-stop cycles, benefit from frictional safety couplings that provide automatic re-engagement and smooth torque transmission.

4.2 Renewable Energy

The renewable energy sector, particularly wind power, relies heavily on safety couplings to protect critical components from harsh operating conditions. Wind turbines are exposed to variable wind speeds, which can cause sudden torque spikes in the transmission system. Safety couplings installed between the turbine rotor and gearbox prevent damage to the gearbox and generator by limiting the torque transmitted during high-wind events.

In solar energy systems, safety couplings are used in solar trackers, which adjust the position of solar panels to maximize sunlight absorption. These couplings protect the tracker motor and drive mechanism from overloads caused by wind resistance or mechanical jams. As the demand for renewable energy grows, the use of safety couplings in this sector is expected to increase significantly.

4.3 Heavy Industry and Mining

Heavy industry and mining operations involve large-scale equipment such as crushers, grinders, excavators, and conveyors, which operate under extreme torque and harsh conditions. Shear bolt and hydraulic safety couplings are commonly used in these applications to handle high torque loads and sudden overloads. For example, crushers, which are used to break down large rocks and minerals, are prone to overloads caused by uncrushable materials (such as metal debris). Safety couplings prevent damage to the crusher's drive system by interrupting power transmission when such overloads occur.

Excavators and other construction machinery use safety couplings to protect the hydraulic pump and engine from damage caused by sudden loads or jams. These couplings ensure that the machinery can operate reliably in demanding environments, minimizing downtime and maintenance costs.

4.4 Transportation

The transportation sector, including rail and marine transportation, uses safety couplings to ensure the safety and reliability of vehicles. Rail freight locomotives and wagons are equipped with couplings that connect individual railcars and transmit traction force. Modern rail couplings, such as hybrid digital automatic couplers, incorporate safety features to prevent damage to the coupling mechanism and railcar components during coupling and braking.

Marine propulsion systems use hydraulic and magnetic safety couplings to protect the engine and propeller from damage caused by underwater obstacles or sudden changes in load. These couplings ensure smooth power transmission and reliable operation in harsh marine environments.

4.5 Food and Pharmaceutical Processing

The food and pharmaceutical industries require equipment that is easy to clean and free from contamination. Magnetic safety couplings are ideal for these applications because of their non-contact operation and sealed design, which prevents lubricants or contaminants from entering the product stream. They are used in pumps, mixers, and conveyors to protect the equipment from overloads while maintaining the hygiene standards required in these industries.

5. Core Values of Safety Couplings: Beyond Equipment Protection

The value of safety couplings extends far beyond protecting equipment from damage. They play a critical role in reducing operational costs, improving system reliability, and ensuring workplace safety. Below are the three core values of safety couplings.

5.1 Protecting Equipment and Reducing Maintenance Costs

The most obvious value of safety couplings is their ability to prevent damage to expensive equipment such as motors, gearboxes, and generators. Repairing or replacing these components can be extremely costly, and downtime caused by equipment failure can result in significant production losses. By interrupting power transmission during overloads, safety couplings minimize the risk of catastrophic failure, reducing maintenance costs and extending the lifespan of the equipment.

For example, in a manufacturing plant, a single gearbox replacement can cost tens of thousands of dollars, and downtime can result in lost revenue of thousands of dollars per hour. A safety coupling installed between the motor and gearbox can prevent this damage, saving the plant from substantial financial losses.

5.2 Improving System Reliability and Operational Continuity

Safety couplings improve the overall reliability of mechanical systems by ensuring stable torque transmission and preventing unexpected failures. Many types of safety couplings, such as frictional and ball-engagement designs, can re-engage automatically after overloads, allowing production to resume quickly without manual intervention. This reduces downtime and ensures operational continuity, which is critical for industries with high production demands.

In addition, safety couplings can accommodate minor shaft misalignments and reduce vibration, which further improves system reliability. By minimizing the stress on other components, they help to extend the lifespan of the entire transmission system.

5.3 Ensuring Workplace Safety

Equipment failures can pose significant safety risks to workers, including flying debris, machine entrapment, and electrical hazards. Safety couplings reduce these risks by preventing catastrophic failures that could lead to accidents. For example, in a mining operation, a crusher failure could result in rocks or debris being ejected, endangering nearby workers. A safety coupling installed in the crusher's drive system can prevent this failure, ensuring the safety of the workforce.

In addition, safety couplings can be integrated with sensors and emergency stop systems to provide additional safety layers. For example, a proximity switch can detect when a safety coupling has disengaged and trigger an emergency stop, further protecting workers from harm.

6. Evolving Trends: The Future of Safety Couplings

As industrial technology advances, safety couplings are evolving to meet the changing needs of modern mechanical systems. The key trends shaping the future of safety couplings include (intelligent monitoring), high torque density, lightweight design, and integration with digital systems.

6.1 Intelligent Monitoring and Predictive Maintenance

The integration of sensors and IoT (Internet of Things) technology is transforming safety couplings into intelligent components that can monitor torque, temperature, vibration, and wear in real-time. These smart safety couplings can transmit data to a central control system, allowing operators to monitor the condition of the coupling and predict potential failures before they occur. This enables predictive maintenance, which reduces downtime and maintenance costs by allowing repairs to be scheduled before a failure occurs.

For example, a smart safety coupling installed in a wind turbine can monitor the torque transmitted between the rotor and gearbox, alerting operators to abnormal torque patterns that may indicate a potential failure. This allows maintenance teams to inspect and repair the coupling before it fails, preventing costly downtime and equipment damage.

6.2 High Torque Density and Compact Design

As machinery becomes more compact and powerful, there is a growing demand for safety couplings with high torque density (torque capacity per unit volume). Manufacturers are developing couplings using advanced materials such as high-strength alloys and composites to achieve higher torque capacity without increasing the size of the coupling. This allows safety couplings to be used in compact equipment such as electric vehicles, robotics, and small-scale renewable energy systems.

Compact safety couplings are also beneficial for applications where space is limited, such as in machine tools and aerospace equipment. By reducing the size and weight of the coupling, manufacturers can improve the overall efficiency and performance of the system.

6.3 Lightweight and Environmentally Friendly Materials

The push for sustainability and energy efficiency is driving the use of lightweight and environmentally friendly materials in safety coupling manufacturing. Materials such as aluminum alloys, titanium, and composite materials are replacing traditional steel in some applications, reducing the weight of the coupling and improving energy efficiency. These materials also offer excellent corrosion resistance, making them suitable for harsh environments such as marine and offshore applications.

In addition, manufacturers are adopting more sustainable production processes, such as reducing energy consumption and using recyclable materials, to minimize the environmental impact of safety coupling production.

6.4 Integration with Digital Transmission Systems

As digital technology becomes more prevalent in industrial systems, safety couplings are being integrated with digital transmission systems such as servo drives and industrial Ethernet. This integration allows for precise control of the coupling's torque setting and disengagement behavior, improving the overall performance and flexibility of the system. For example, in a smart factory, a safety coupling can be controlled remotely via an industrial Ethernet network, allowing operators to adjust the torque threshold based on the specific production task.

In the rail industry, hybrid digital automatic couplers are being developed that integrate safety coupling functions with digital communication systems, enabling seamless communication between railcars and improving the efficiency of rail freight operations.

7. Conclusion

Safety couplings are essential components of modern mechanical transmission systems, providing a critical balance between power transmission and equipment protection. Their diverse working mechanisms, types, and applications make them versatile for use across industries ranging from manufacturing and renewable energy to heavy industry and transportation. The core values of safety couplings—protecting equipment, improving reliability, and ensuring workplace safety—make them indispensable for reducing operational costs and maintaining production continuity.

As technology advances, safety couplings are evolving to meet the changing needs of modern industry, with trends such as intelligent monitoring, high torque density, and digital integration shaping their future. By embracing these trends, manufacturers can develop safety couplings that are more efficient, reliable, and adaptable, further enhancing their role as guardians of mechanical systems.

In a world where industrial efficiency and safety are paramount, safety couplings will continue to play a vital role in supporting the growth and development of modern engineering and manufacturing. Their unsung contribution to operational reliability and safety makes them a cornerstone of industrial progress.

« Safety Couplings » Post Date: 2023/10/9