Bush Couplings

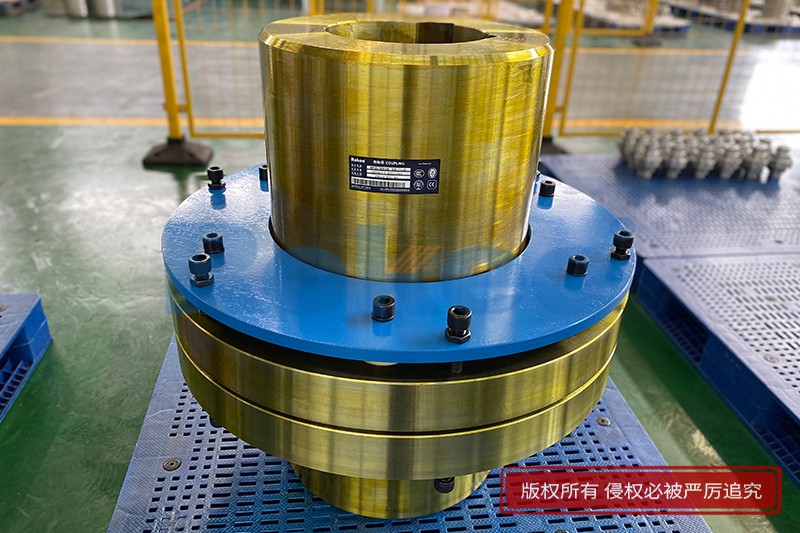

Rokee is Bush Couplings Manufacturer, Customizable according to the bush couplings drawings provided by the customer, Support Export.

The design of the Bush Coupling is simple and clever in design and has wide applicability. Bush Coupling uses the pin with elastic sleeve to connect two semi-couplings with pin holes to realize torque transmission and larger angular compensation. At the same time, Bush Coupling has good shock absorption and buffering performance, which can be used in high-speed occasions without lubrication and requiring easy pin sleeve replacement.

LT/TL Elastic Sleeve Pin Coupling

Basic Type

LT Elastic Sleeve Pin Coupling is the basic form of this series of couplings.View MoreLTZ/TLL Elastic Sleeve Pin Coupling

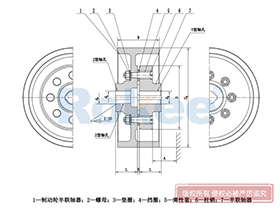

With Brake Wheel

LTZ Elastic Sleeve Pin Coupling is designed with a brake wheel, suitable for situations where braking is required.View More

In the realm of mechanical power transmission, couplings serve as indispensable components that bridge rotating shafts, enabling the seamless transfer of torque while accommodating inevitable misalignments and mitigating operational stresses. Among the diverse array of coupling types, bush couplings stand out for their balance of simplicity, flexibility, and cost-effectiveness, making them a staple in numerous industrial and commercial applications.

1. Understanding Bush Couplings: Definition and Core Functions

A bush coupling, also commonly referred to as a pin bush coupling, is a type of flexible coupling designed to connect two rotating shafts at their ends for the primary purpose of transmitting torque. Unlike rigid couplings, which require precise shaft alignment and offer no flexibility, bush couplings incorporate elastic elements that allow for a degree of misalignment—including angular, parallel, and axial displacement—between the connected shafts. This flexibility is the defining characteristic of bush couplings, as it protects the coupled machinery from excessive stress, reduces vibration transmission, and absorbs shock loads that may occur during startup, shutdown, or variable load operations.

The core functions of a bush coupling extend beyond mere torque transmission. First and foremost, it must establish a secure connection between shafts to prevent slippage, ensuring efficient power transfer without energy loss. Secondly, it must compensate for shaft misalignments that may arise due to manufacturing tolerances, installation errors, thermal expansion or contraction of machinery, or structural deflection under load. Thirdly, it acts as a damping element, absorbing vibrations and shocks to minimize wear and tear on critical components such as motors, pumps, and gearboxes. Finally, in some configurations, bush couplings facilitate easier installation and disassembly, simplifying maintenance and repair processes.

2. Structural Composition and Working Principle

2.1 Basic Structural Components

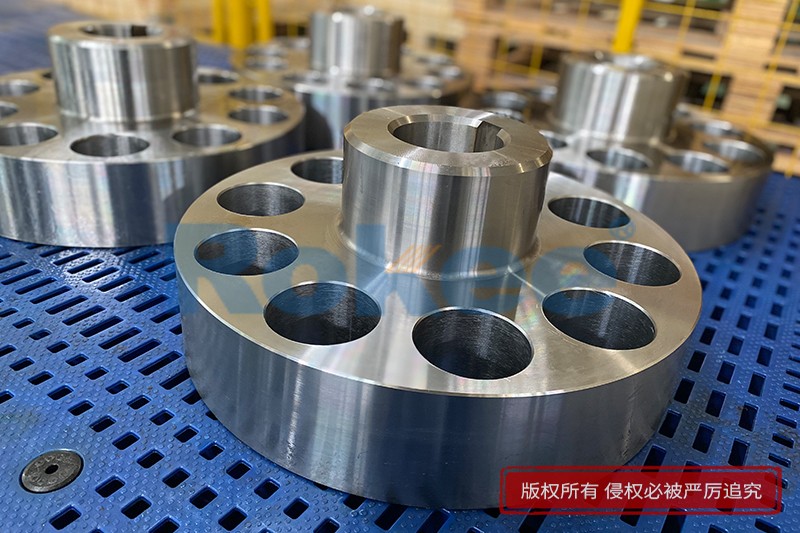

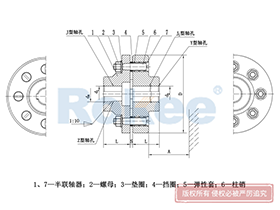

The structure of a bush coupling is relatively straightforward, consisting of four primary components that work in tandem to achieve torque transmission and flexibility: two flanges (semi-couplings), pins, bushes (elastic sleeves), and fasteners (such as nuts or cotter pins).

The two flanges, often referred to as semi-couplings, are the primary connecting elements that attach to the ends of the two shafts to be coupled. These flanges are typically disc-shaped and feature a series of evenly spaced holes around their circumference, which accommodate the pins and bushes. The flanges are designed to be rigid enough to withstand the torque loads they transmit, and their connection to the shafts is usually achieved through keyways and set screws, or in some cases, interference fits for higher torque applications.

Pins are cylindrical metallic components that pass through the holes in both flanges, forming the mechanical link between the two semi-couplings. The number and diameter of the pins are determined by the torque capacity required for the specific application—higher torque demands more or larger-diameter pins. The pins are secured in place using fasteners to prevent axial movement during rotation.

Bushes, the elastic elements that give bush couplings their flexibility, are inserted between the pins and the flange holes. These bushes are typically made from non-metallic materials such as rubber, neoprene, polyurethane, or other elastomers, though in some specialized applications, composite materials may be used. The bushings act as a buffer between the rigid metallic pins and flanges, absorbing vibrations and allowing for relative movement between the components to compensate for shaft misalignment.

2.2 Working Principle

The operating principle of a bush coupling is based on the transfer of torque through the mechanical interaction of its components, with the bushes enabling flexibility and damping. When one shaft (typically the driver shaft connected to a motor or engine) rotates, it imparts rotational motion to the corresponding flange. This rotational force is transmitted to the pins inserted in the flange holes. As the pins rotate, they exert pressure on the bushes, which in turn transfer the torque to the second flange (connected to the driven shaft, such as a pump, compressor, or conveyor).

The key to the coupling’s flexibility lies in the deformation of the bushes. When there is misalignment between the two shafts, the bushes compress and expand asymmetrically as the flanges rotate, allowing the pins to move slightly within the flange holes without causing excessive stress. This deformation also absorbs vibrations generated by the rotating shafts, preventing them from being transmitted to the connected machinery. Additionally, during sudden load changes or shock loads (such as when a conveyor encounters an obstruction), the bushes act as a shock absorber, cushioning the impact and reducing the risk of component failure.

It is important to note that bush couplings operate without the need for lubrication, as the non-metallic bushes eliminate metal-to-metal contact between the pins and flanges. This not only simplifies maintenance but also reduces the risk of contamination in applications where lubricant leakage could be problematic, such as in food processing or pharmaceutical industries.

3. Classification of Bush Couplings

Bush couplings are available in several configurations, each tailored to specific application requirements such as torque capacity, speed, misalignment tolerance, and maintenance accessibility. The most common classifications are based on their design variations, including the following types:

3.1 Basic Flange-Type Bush Coupling

This is the simplest and most widely used type of bush coupling. It consists of two identical flanges with evenly spaced holes, pins, and bushes. The flanges are directly attached to the shafts, and the pins pass through the bushes in the flange holes to connect the two halves. This design is suitable for low to medium torque and speed applications, such as small electric motors driving pumps or fans. It offers moderate misalignment compensation and is easy to manufacture and install.

3.2 Spacer-Type Bush Coupling

In spacer-type bush couplings, a spacer element is inserted between the two flanges, creating a gap between the connected shafts. This design is ideal for applications where there is a need to separate the driver and driven machinery, such as in pump systems where the motor and pump are mounted at a distance, or in applications where maintenance access to the equipment between the shafts is required. The spacer can be removed without moving the connected shafts, simplifying disassembly. This type retains the flexibility and damping characteristics of basic bush couplings but is designed to accommodate longer shaft distances.

3.3 Elastic Sleeve Pin Coupling

The elastic sleeve pin coupling is a specialized variant where the bushes (elastic sleeves) are designed to fit tightly around the pins, with the outer surface of the sleeves making contact with the flange holes. This design enhances the coupling’s shock absorption and vibration damping capabilities, making it suitable for higher speed applications. The elastic sleeves are typically replaceable, allowing for easy maintenance without replacing the entire coupling. This type is commonly used in applications such as electric motors, compressors, and turbines where smooth operation at moderate to high speeds is critical.

3.4 Split-Type Bush Coupling

Split-type bush couplings feature flanges that are split into two halves, held together by bolts. This design allows for installation and removal of the coupling without requiring axial movement of the shafts, which is particularly advantageous in applications where the shafts are already installed or where space constraints prevent axial movement. This type is widely used in conveyor systems, cranes, and other heavy machinery where frequent maintenance or coupling replacement may be necessary.

3.5 Brake Wheel-Equipped Bush Coupling

This variant incorporates a brake wheel into one of the flanges, enabling the coupling to perform both torque transmission and braking functions. The brake wheel is designed to work with a brake system to stop the rotation of the shafts quickly when needed. This type is commonly used in applications such as cranes, hoists, and conveyors, where precise braking is essential for safety and operational control.

4. Material Selection for Bush Couplings

The performance, durability, and suitability of a bush coupling for a specific application are heavily dependent on the materials used for its components. The selection of materials is guided by factors such as torque capacity, operating speed, temperature range, environmental conditions (e.g., corrosion, moisture, chemicals), and load characteristics (e.g., shock loads, continuous vs. intermittent operation). Below is a breakdown of material considerations for each key component:

4.1 Flanges and Pins

Flanges and pins are typically made from metallic materials due to their need to withstand high torque and rotational stresses. The most common materials include:

- Carbon Steel: This is the most widely used material for flanges and pins due to its high strength, durability, and cost-effectiveness. Carbon steel is suitable for most low to medium torque applications and can be heat-treated to enhance its hardness and wear resistance.

- Alloy Steel: For high torque or heavy-duty applications, alloy steel (e.g., chromium-molybdenum steel) is preferred. Alloy steel offers higher tensile strength and fatigue resistance than carbon steel, making it suitable for machinery such as crushers, rolling mills, and large conveyors.

- Aluminum Alloy: In applications where weight is a critical factor (e.g., lightweight machinery, aerospace auxiliary systems), aluminum alloy is used. Aluminum is lightweight, corrosion-resistant, and has good thermal conductivity, though it has lower torque capacity than steel.

- Stainless Steel: For applications in corrosive environments (e.g., marine, chemical processing, food processing), stainless steel is selected. Stainless steel resists rust and chemical degradation, ensuring long-term performance in harsh conditions.

4.2 Bushes (Elastic Elements)

The choice of bush material is critical for the coupling’s flexibility, damping capacity, and temperature resistance. Common bush materials include:

- Natural Rubber: Offers excellent elasticity and vibration damping but has limited temperature resistance (typically -20°C to 60°C). Suitable for general-purpose applications with moderate operating temperatures.

- Neoprene: A synthetic rubber that provides better oil and chemical resistance than natural rubber, with a wider temperature range (-40°C to 100°C). Ideal for applications where the coupling may be exposed to oils or mild chemicals.

- Polyurethane: Combines high tensile strength with good elasticity and wear resistance. Polyurethane bushes have a temperature range of -30°C to 80°C and are suitable for applications requiring higher torque capacity and durability than rubber bushes.

- Silicone Rubber: Offers excellent high-temperature resistance (up to 200°C) and good electrical insulation properties. Suitable for high-temperature applications such as exhaust fans, heaters, or industrial ovens.

- Composite Materials: In specialized applications, composite materials (e.g., fiber-reinforced polymers) are used to provide a balance of strength, light weight, and corrosion resistance. These materials are often used in aerospace or marine applications where weight and durability are paramount.

5. Applications of Bush Couplings Across Industries

The versatility of bush couplings—stemming from their simple design, flexibility, low maintenance requirements, and cost-effectiveness—makes them suitable for a wide range of industries and applications. Below are some of the key sectors where bush couplings are commonly employed, along with specific use cases:

5.1 Industrial Machinery and Manufacturing

In general manufacturing facilities, bush couplings are used in a variety of machinery, including pumps, compressors, fans, and blowers. For example, in water treatment plants, bush couplings connect electric motors to centrifugal pumps, accommodating minor misalignments caused by pipe stress or foundation settlement while transmitting torque efficiently. In air compression systems, they dampen vibrations from the compressor motor, reducing wear on the motor bearings and the compressor itself. Additionally, bush couplings are used in conveyor systems—both belt and chain conveyors—to connect the drive motor to the conveyor shaft, absorbing shocks from uneven loads or obstructions on the conveyor belt.

5.2 Automotive and Transportation

In the automotive industry, bush couplings are used in auxiliary systems such as water pumps, oil pumps, and alternators, connecting these components to the engine crankshaft. Their flexibility compensates for the slight misalignments that occur due to engine vibration and thermal expansion. In commercial transportation, such as trucks and buses, bush couplings are used in air brake systems and power steering pumps, ensuring reliable torque transmission in harsh operating conditions. They are also employed in railway applications, such as in the drive systems of small locomotives or rail maintenance equipment.

5.3 Marine and Offshore

Marine environments pose unique challenges, including corrosion, high humidity, and variable loads. Bush couplings made from corrosion-resistant materials (e.g., stainless steel flanges and neoprene bushes) are used in marine applications such as connecting the engine to the propeller shaft in small boats and ships. They also find use in offshore equipment, such as pumps and winches on oil rigs, where their ability to absorb shock and accommodate misalignments is critical for reliable operation in rough seas.

5.4 Mining and Construction

Mining and construction machinery operate under heavy loads, high torque, and severe shock conditions. Bush couplings are used in equipment such as crushers, grinders, bucket elevators, and excavators. For example, in a stone crusher, the bush coupling connects the motor to the crusher’s drive shaft, absorbing the shock loads generated when large rocks are crushed and accommodating misalignments caused by the machinery’s movement during operation. In construction equipment, such as concrete mixers, bush couplings ensure smooth torque transmission from the engine to the mixing drum, even under variable load conditions.

5.5 Food and Pharmaceutical Processing

In food and pharmaceutical industries, hygiene and contamination control are paramount. Bush couplings are ideal for these applications because they do not require lubrication, eliminating the risk of lubricant leakage contaminating food products or pharmaceutical ingredients. They are used in mixers, blenders, conveyors, and packaging equipment, connecting motors to the processing components while maintaining a clean operating environment.

5.6 Power Generation

In power generation facilities, both conventional (e.g., coal-fired, gas-fired) and renewable (e.g., wind, hydroelectric), bush couplings are used in auxiliary systems such as cooling tower fans, water circulation pumps, and fuel handling equipment. Their ability to transmit torque efficiently and absorb vibrations ensures the reliable operation of these critical systems, which are essential for the continuous generation of power.

6. Maintenance and Troubleshooting of Bush Couplings

Proper maintenance is essential to ensure the longevity and reliable performance of bush couplings. One of the key advantages of bush couplings is their low maintenance requirements, but regular inspections and timely replacement of worn components are still necessary to prevent unexpected failures. Below are the essential maintenance practices and common troubleshooting tips:

6.1 Regular Inspection

Routine inspections should be conducted at regular intervals (depending on the application and operating conditions) to check for signs of wear, damage, or misalignment. Key inspection points include:

- Bushes: Check for cracks, hardening, or excessive wear. Elastomeric bushes degrade over time due to age, heat, and exposure to chemicals, which reduces their flexibility and damping capacity. A worn bush may cause increased vibration, noise, or reduced torque transmission.

- Pins and Flanges: Inspect for signs of corrosion, bending, or wear on the pin surfaces and flange holes. Metal-to-metal contact between pins and flanges (caused by worn bushes) can lead to excessive wear and damage to the flanges and pins.

- Fasteners: Ensure that nuts, cotter pins, or other fasteners are tight and secure. Loose fasteners can cause the pins to move axially, leading to misalignment and increased wear.

- Shaft Alignment: Check the alignment of the connected shafts. Over time, foundation settlement, machinery vibration, or thermal expansion can cause misalignment, which places additional stress on the coupling and the connected components.

6.2 Component Replacement

The most frequently replaced component in a bush coupling is the bush. When bushes show signs of wear or damage, they should be replaced promptly to prevent damage to the pins and flanges. Replacement of bushes is a simple process that typically involves removing the fasteners, extracting the old pins and bushes, and installing new bushes and pins. It is important to use the correct size and material of bushes for the specific application to ensure optimal performance.

If the pins or flanges are worn or damaged, they should also be replaced. In some cases, it may be more cost-effective to replace the entire coupling rather than individual components, especially if the flanges are severely worn or cracked.

6.3 Troubleshooting Common Issues

Common issues that may arise with bush couplings include excessive vibration, noise, reduced torque transmission, and coupling failure. Below are the typical causes and solutions for these issues:

- Excessive Vibration: This is often caused by worn bushes, misaligned shafts, or loose fasteners. The solution involves replacing worn bushes, realigning the shafts, and tightening loose fasteners.

- Unusual Noise (e.g., squeaking, rattling): Noise is typically a sign of metal-to-metal contact, which occurs when the bushes are worn out. Replacing the bushes will resolve this issue.

- Reduced Torque Transmission or Slippage: This may be caused by loose fasteners, worn pins, or insufficiently tight flange-shaft connections. Tightening fasteners, replacing worn pins, or ensuring a secure fit between the flanges and shafts (e.g., checking keyway integrity) will address this problem.

- Coupling Failure: Severe failure, such as flange cracking or pin bending, is usually caused by overloading, excessive misalignment, or using the wrong coupling for the application. The solution involves replacing the failed coupling with one that is rated for the correct torque and misalignment range, and addressing the root cause (e.g., reducing overloads, realigning shafts).

7. Advantages and Limitations of Bush Couplings

7.1 Key Advantages

Bush couplings offer several advantages that contribute to their widespread use across industries:

- Simplicity and Cost-Effectiveness: Their simple design makes them easy to manufacture, install, and maintain, resulting in lower initial and operational costs compared to more complex coupling types (e.g., gear couplings, disc couplings).

- Flexibility and Misalignment Compensation: The elastic bushes allow for angular, parallel, and axial misalignments, reducing stress on connected machinery and extending component life.

- Vibration Damping and Shock Absorption: The non-metallic bushes absorb vibrations and cushion shock loads, improving the smoothness of operation and reducing wear on motors, bearings, and other components.

- No Lubrication Required: Unlike gear or chain couplings, bush couplings do not need lubrication, simplifying maintenance and eliminating the risk of lubricant contamination.

- Wide Range of Applications: Available in various sizes and configurations, bush couplings can be tailored to suit low to medium torque, low to high speed, and diverse environmental conditions.

7.2 Limitations

Despite their many advantages, bush couplings have certain limitations that restrict their use in some applications:

- Limited Torque Capacity: Compared to rigid couplings or gear couplings, bush couplings have a lower torque capacity, making them unsuitable for very high-torque applications (e.g., large industrial turbines, heavy-duty marine propulsion systems).

- Temperature Constraints: Elastomeric bushes have temperature limits; exposure to temperatures beyond their range can cause premature degradation, limiting their use in extreme high or low-temperature environments.

- Limited Misalignment Range: While they can accommodate minor misalignments, excessive misalignment (beyond the coupling’s design limits) can lead to premature wear and failure. For applications with significant misalignments, other coupling types (e.g., universal joints, oldham couplings) may be more suitable.

- Bushes Degrade Over Time: Elastomeric materials degrade due to age, ozone, and chemical exposure, requiring regular replacement to maintain performance.

8. Conclusion

Bush couplings are a vital component in mechanical power transmission systems, offering a balance of simplicity, flexibility, and cost-effectiveness that makes them indispensable across a wide range of industries. Their ability to transmit torque efficiently while accommodating misalignments, absorbing vibrations, and requiring minimal maintenance has solidified their position as a preferred choice for applications ranging from small electric motors to heavy-duty construction machinery.

Understanding the structural composition, working principle, classification, and material selection criteria of bush couplings is essential for selecting the right coupling for a specific application. Proper maintenance practices, including regular inspections and timely replacement of worn bushes, ensure their reliable performance and longevity. While bush couplings have limitations in terms of torque capacity and temperature range, their advantages far outweigh these constraints for most low to medium torque applications.

As industrial machinery continues to evolve, with increasing demands for efficiency, reliability, and sustainability, bush couplings are likely to remain a key component in power transmission systems. Their adaptability, low environmental impact (due to no lubrication requirements), and cost-effectiveness make them well-suited to meet the needs of modern industries, from food processing and pharmaceuticals to mining and renewable energy. By leveraging the unique capabilities of bush couplings, engineers and maintenance professionals can optimize the performance and lifespan of the machinery they operate, ensuring seamless and efficient power transmission in diverse operating conditions.

« Bush Couplings » Post Date: 2023/10/9

URL: http://www.rokee.com/en/tags/bush-couplings.html