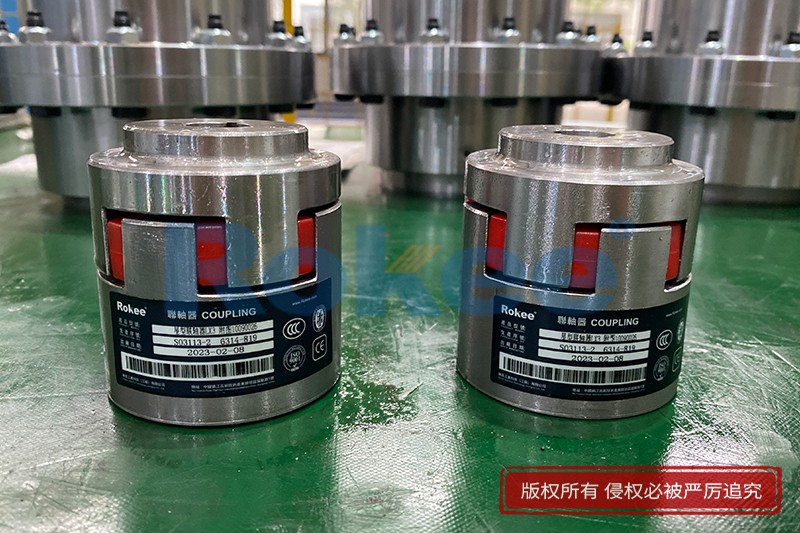

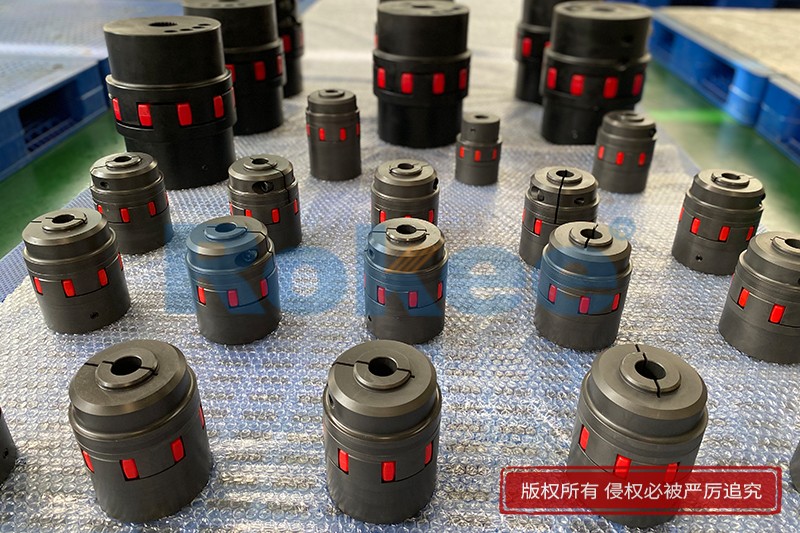

Spider Couplings

Rokee is Spider Couplings Manufacturer, Customizable according to the spider couplings drawings provided by the customer, Support Export.

Spider Couplings is an elastic component made of engineering plastic, suitable for connecting two coaxial transmission shaft systems. It has compensation for relative deviation between two shafts, buffering, shock absorption, and wear resistance. It is widely used in various occasions, with a transmission torque of 20-35000 N.M and a working temperature of -35-+80 degrees Celsius. Polyurethane elastomers are limited by convex claw blocks.

In the realm of mechanical power transmission, couplings serve as the critical interface between rotating shafts, ensuring the seamless transfer of torque while accommodating inevitable misalignments and mitigating operational stresses. Among the diverse array of coupling technologies, spider couplings—also commonly referred to as jaw couplings—stand out for their unique combination of flexibility, simplicity, and cost-effectiveness. These flexible couplings have become indispensable components in countless industrial, automotive, and precision machinery applications, playing a pivotal role in enhancing system reliability and extending equipment lifespan.

1. Understanding Spider Couplings: Definition and Core Components

A spider coupling is a type of torsionally flexible coupling designed to connect two rotating shafts in power transmission systems, facilitating torque transfer while compensating for three primary types of shaft misalignment: angular, parallel, and axial displacements. Unlike rigid couplings, which require near-perfect alignment and offer no vibration dampening, spider couplings incorporate a flexible intermediate element that absorbs shocks and reduces vibrational forces, thereby protecting connected equipment such as motors, gearboxes, and pumps.

The basic structure of a spider coupling consists of three essential components, each contributing to its overall functionality:

1. Hubs: The two hubs form the connection points to the driving and driven shafts. Typically manufactured from metallic materials such as aluminum, steel, or cast iron, hubs are engineered with a series of radially projecting jaw-like structures that interlock with the spider element. The choice of hub material is dictated by the application's torque requirements, operating environment, and space constraints—aluminum hubs offer lightweight properties for high-speed applications, while steel or cast iron hubs provide enhanced durability for heavy-duty operations. Hubs are secured to shafts using various methods, including set screws, clamping mechanisms, or taper bushings, ensuring a backlash-free connection that minimizes power loss.

2. Spider Element: The central "spider"—the defining component of this coupling type—is a flexible insert that fits snugly between the two hubs. Constructed from elastomeric materials such as polyurethane, rubber, or composite blends, the spider features a star-shaped or cross-shaped profile with lobes that match the jaw configuration of the hubs. The elastomeric nature of the spider is critical to its performance: it enables flexibility to accommodate misalignment, acts as a vibration damper, and absorbs shock loads generated during startup or operational disturbances. Some spider elements are reinforced with metallic inserts to enhance torque capacity, while specialized formulations may offer resistance to chemicals, extreme temperatures, or UV radiation for harsh environment applications.

3. Optional Bushing Components: In certain designs, spider couplings may include bushing elements that connect the spider to the hubs, providing additional support and facilitating easier replacement of the flexible element without disassembling the entire shaft assembly. These bushings are typically made from materials compatible with both the hub and spider, ensuring a secure fit and maintaining the coupling's overall flexibility.

2. Working Principles of Spider Couplings

The operational mechanism of a spider coupling is grounded in the synergistic interaction between its rigid hubs and flexible spider element. The core principle revolves around transmitting torque while isolating the connected shafts from harmful misalignments and vibrational forces. Here’s a detailed breakdown of the working process:

When the driving shaft rotates, it imparts rotational force to the attached hub. The jaws of this driving hub engage with the lobes of the elastomeric spider, causing the spider to twist slightly under the torque load. This torsional deformation of the spider transfers the rotational force to the driven hub, which in turn rotates the driven shaft. Crucially, the flexibility of the spider element allows this torque transfer to occur even when the two shafts are not perfectly aligned.

For angular misalignment—where the shafts are inclined at an angle relative to each other—the spider’s lobes flex unevenly, accommodating the angular offset without creating excessive stress on the shafts or bearings. In the case of parallel misalignment—where the shafts are offset horizontally but remain parallel—the spider’s lateral flexibility allows the hubs to maintain engagement while bridging the gap between the shafts. Axial misalignment, caused by thermal expansion or contraction of shafts during operation, is compensated for by the spider’s ability to compress or extend slightly along the axis of rotation.

Beyond misalignment compensation, the elastomeric spider serves as a critical damping component. Vibrations generated by the driving shaft—whether from motor imbalance, uneven load distribution, or operational fluctuations—are absorbed by the spider’s material, preventing their transmission to the driven equipment. This damping effect not only reduces noise levels but also minimizes wear and tear on bearings, seals, and other precision components, significantly extending the service life of the entire power transmission system.

3. Classification of Spider Couplings: Design Variations and Their Characteristics

Spider couplings are available in several design variations, each tailored to specific application requirements such as torque capacity, space constraints, operating speed, and maintenance accessibility. The primary classifications are based on hub configuration, spider material, and the inclusion of additional components. Below are the most common types:

3.1 Two-Piece Spider Couplings

The two-piece design is the most widely used configuration of spider couplings, consisting of two separate metallic hubs and a central elastomeric spider. This design offers exceptional ease of installation and maintenance, as the spider can be replaced without disassembling the entire shaft assembly or moving the connected equipment. The hubs are typically designed with curved jaws, which distribute the torque more evenly across the spider’s lobes and reduce stress concentrations. Two-piece spider couplings excel in low to moderate speed applications with high torque requirements, such as industrial conveyors, pumps, and electric motors. Key advantages include excellent vibration damping, durable performance under heavy loads, and compatibility with a wide range of shaft diameters. However, they are not ideal for high-speed applications, as the elastomeric spider may experience excessive heat buildup or deformation at elevated rotational speeds.

3.2 Single Flywheel Spider Couplings

This design integrates a single metallic flywheel assembly with two hubs connected via a central spider element. Engineered for compactness and simplicity, single flywheel spider couplings are well-suited for applications with space constraints, such as small engines, automotive drivetrains, and lightweight industrial machinery. The flywheel component helps to smooth out rotational fluctuations, enhancing the coupling’s torque transmission stability. Advantages include a lightweight and compact form factor, easy installation, and effective noise reduction. However, they have lower torque capacity compared to two-piece designs and may require full disassembly for spider replacement, making them less suitable for high-stress or heavy-duty applications.

3.3 Hybrid Spider Couplings with Gear Elements

Hybrid designs combine the flexibility of spider couplings with the high torque capacity of gear couplings. These couplings feature metallic gear teeth on the hubs, with an elastomeric spider insert placed between the gear meshes. The gear teeth provide enhanced torque transmission capabilities, while the spider insert dampens vibrations and accommodates misalignment. Hybrid spider couplings are ideal for heavy-duty industrial applications such as compressors, turbines, and mining equipment, where high torque and moderate misalignment are common. Key advantages include high torque and speed capability, durability in severe operating conditions, and improved misalignment tolerance. However, they are more complex and expensive than standard spider couplings and may require regular lubrication to maintain optimal performance.

3.4 Spider Couplings with Shaft Locking Elements

Some spider couplings incorporate shaft locking elements (such as friction-based locking mechanisms) in place of traditional keyways and set screws. These locking elements create a backlash-free connection between the hub and shaft, eliminating the need for additional components like lock washers or spacers. This design simplifies installation and removal, making it ideal for applications where frequent maintenance is required. Shaft locking elements also distribute the clamping force evenly across the shaft surface, reducing stress concentrations and minimizing shaft damage. These couplings are commonly used in precision machinery, robotics, and automation systems, where precise torque transmission and easy maintenance are critical.

4. Key Advantages of Spider Couplings in Power Transmission Systems

Spider couplings offer a unique set of advantages that make them a preferred choice across numerous industries. Their design balances flexibility, torque capacity, and ease of maintenance, addressing the most common challenges in power transmission systems. The primary advantages include:

4.1 Versatile Misalignment Compensation

One of the most significant benefits of spider couplings is their ability to accommodate all three types of shaft misalignment—angular, parallel, and axial. This versatility eliminates the need for precise shaft alignment during installation, reducing setup time and labor costs. By compensating for misalignment, spider couplings prevent excessive stress on shafts, bearings, and seals, which are major causes of premature equipment failure. In applications where thermal expansion or contraction is common (such as in high-temperature industrial processes), the axial flexibility of spider couplings ensures consistent performance without compromising torque transmission.

4.2 Effective Vibration and Shock Absorption

The elastomeric spider element acts as a natural vibration damper, absorbing vibrational forces generated by the driving shaft and preventing their transmission to the driven equipment. This damping effect reduces noise levels in operational environments and minimizes wear on precision components. Additionally, spider couplings excel at absorbing shock loads—such as those caused by sudden startup, equipment overload, or operational disturbances. By cushioning these shocks, the spider element protects sensitive machinery (such as motors and gearboxes) from damage, extending their service life and reducing maintenance costs.

4.3 Easy Installation and Maintenance

Spider couplings are designed for simplicity, with most configurations requiring no specialized tools for installation. The two-piece design, in particular, allows for easy replacement of the spider element without disassembling the entire shaft assembly or moving heavy equipment. This reduces downtime during maintenance, a critical advantage in industrial settings where productivity is paramount. Unlike rigid couplings or gear couplings, which may require precise alignment or regular lubrication, spider couplings are typically maintenance-free (except for periodic spider replacement), further reducing operational costs.

4.4 Cost-Effective Performance

Compared to other flexible coupling technologies (such as disc couplings or bellows couplings), spider couplings offer a cost-effective solution for power transmission. Their simple design requires fewer components, reducing manufacturing and material costs. Additionally, their durability and low maintenance requirements minimize long-term operational expenses. For applications with moderate torque requirements and misalignment challenges, spider couplings provide a balance of performance and cost that is difficult to match with other coupling types.

4.5 Wide Torque and Speed Range

Spider couplings are available in a range of sizes and configurations, capable of transmitting torque from low to high values (up to 28,000 Nm in some heavy-duty designs) and operating at speeds up to 19,000 rpm. This versatility makes them suitable for a wide range of applications, from small automotive accessories to large industrial machinery. The torque capacity and speed range can be further optimized by selecting the appropriate hub material and spider elastomer, ensuring compatibility with specific application requirements.

4.6 No Metal-to-Metal Contact

In standard spider coupling designs, the hubs do not come into direct contact with each other—all torque transmission and misalignment compensation are facilitated by the spider element. This eliminates metal-to-metal wear, a common issue in rigid couplings and gear couplings that can lead to premature failure. The absence of metal-to-metal contact also reduces noise levels and eliminates the need for lubrication in most cases, simplifying maintenance and improving operational cleanliness.

5. Application Versatility: Industries and Use Cases

The unique combination of advantages offered by spider couplings makes them suitable for a diverse range of industries and applications. From industrial manufacturing to automotive, robotics, and aerospace, spider couplings play a critical role in ensuring reliable power transmission. Below are some of the key application areas:

5.1 Industrial Manufacturing and Machinery

In industrial settings, spider couplings are widely used in machinery such as conveyors, pumps, compressors, and machine tools. Conveyor systems, which require consistent torque transmission and the ability to accommodate minor misalignments between motor and roller shafts, benefit from the flexibility and vibration damping of spider couplings. Pumps and compressors, which operate under varying load conditions, rely on spider couplings to absorb shock loads and reduce wear on bearings and seals. Machine tools—such as lathes, milling machines, and grinders—utilize spider couplings to ensure precise torque transmission while minimizing vibrations, which can affect machining accuracy.

5.2 Automotive Industry

The automotive sector leverages spider couplings in various powertrain components and engine-driven accessories. In drivetrain systems, spider couplings connect the driveshaft to the axle, accommodating the angular and axial misalignments that occur during vehicle movement (such as when navigating uneven terrain). They are also used in power steering systems, where flexibility and shock absorption are critical for smooth steering operation. Additionally, spider couplings find applications in small engines (such as those used in motorcycles or lawnmowers), providing a compact and reliable torque transmission solution.

5.3 Robotics and Automation

Precision is paramount in robotics and automation systems, and spider couplings are well-suited for these applications. Robotic arms, which require precise motion control and torque transmission between motors and joints, benefit from the zero-backlash design of many spider couplings. The vibration damping properties of the spider element also ensure smooth operation, reducing wear on delicate robotic components. Automation systems—such as those used in assembly lines or material handling—rely on spider couplings to connect motors to conveyors, actuators, and other components, ensuring consistent performance and minimizing downtime.

5.4 Aerospace and Defense

In the aerospace industry, spider couplings are used in critical systems such as flight control mechanisms, landing gear assemblies, and spacecraft assembly tools. These applications require lightweight, high-strength components that can withstand extreme operating conditions (such as high temperatures and vibrations). Spider couplings with aluminum or composite hubs and specialized elastomeric spiders are ideal for these environments, providing reliable torque transmission while accommodating the misalignments that occur during flight or spacecraft operation. The vibration damping properties also help protect sensitive avionic components from damage.

5.5 Mining and Heavy-Duty Equipment

Mining operations and heavy-duty industrial equipment (such as crushers, excavators, and bulk material handlers) require couplings that can transmit high torque and withstand harsh operating conditions. Spider couplings—particularly hybrid designs with gear elements—are well-suited for these applications, offering high torque capacity, misalignment compensation, and shock absorption. The ability to withstand dust, debris, and extreme temperatures makes them a reliable choice for mining environments, where equipment downtime can result in significant productivity losses.

5.6 Marine and Offshore Applications

Marine environments present unique challenges, including corrosion, high humidity, and saltwater exposure. Spider couplings with stainless steel hubs and corrosion-resistant spider elements are designed to withstand these conditions, making them suitable for use in ship propulsion systems, pumps, and winches. The vibration damping properties also help reduce noise levels on board ships, improving crew comfort and reducing fatigue.

6. Selection Criteria for Spider Couplings

Selecting the appropriate spider coupling for a specific application requires careful consideration of several key factors, including torque requirements, misalignment levels, operating speed, environmental conditions, and space constraints. The following guidelines will help ensure optimal coupling performance and longevity:

6.1 Torque Capacity

The primary consideration when selecting a spider coupling is its torque capacity—the maximum amount of torque it can transmit without failure. The coupling’s torque rating must exceed the maximum torque generated by the driving shaft, including any shock loads or overload conditions. It is recommended to use a service factor (a multiplier applied to the nominal torque) to account for these variables. For example, a service factor of 1.5 to 2.0 is typically used for industrial machinery, while higher service factors may be required for applications with frequent shock loads (such as mining or construction).

6.2 Misalignment Requirements

The coupling must be capable of accommodating the expected levels of angular, parallel, and axial misalignment in the application. Different spider coupling designs have varying misalignment limits—for example, two-piece curved jaw couplings can typically accommodate angular misalignment up to 1.5 degrees and parallel misalignment up to 0.5 mm per 100 mm of shaft distance. It is important to select a coupling with misalignment limits that exceed the expected values, as excessive misalignment can lead to premature spider failure and increased vibration.

6.3 Operating Speed

The operating speed of the shafts (measured in rpm) is another critical factor. High-speed applications (such as those in aerospace or precision machinery) require couplings with balanced designs to minimize centrifugal forces and vibration. Aluminum hubs are preferred for high-speed applications due to their lightweight properties, which reduce rotational inertia. It is important to ensure that the coupling’s maximum allowable speed exceeds the application’s operating speed to prevent excessive heat buildup or structural failure.

6.4 Environmental Conditions

The operating environment has a significant impact on the selection of spider coupling materials. For applications exposed to extreme temperatures, chemicals, UV radiation, or moisture, specialized materials are required. For example, polyurethane spider elements offer better temperature resistance than rubber, while stainless steel hubs are ideal for corrosive environments (such as marine or chemical processing). In high-temperature applications (exceeding 80°C), it may be necessary to select a coupling with a heat-resistant elastomer or metallic spider reinforcement.

6.5 Shaft Sizes and Space Constraints

The coupling must be compatible with the diameters of the driving and driven shafts. Spider couplings are available in a range of standard sizes, typically classified using alphanumeric codes (such as L, M, N, XL) that correspond to specific shaft diameter ranges. It is important to select a coupling with hub inner diameters that match the shaft sizes, ensuring a secure fit. Additionally, space constraints in the application may limit the coupling’s outer diameter or length, making compact designs (such as single flywheel couplings) more suitable.

6.6 Maintenance Accessibility

For applications where downtime must be minimized, the ease of maintenance should be considered. Two-piece spider couplings are preferred in these cases, as they allow for quick spider replacement without disassembling the entire shaft assembly. Couplings with shaft locking elements also simplify installation and removal, reducing maintenance time and labor costs.

7. Maintenance Practices for Spider Couplings

While spider couplings are generally low-maintenance components, proper care and regular inspections are essential to ensure optimal performance and extend their service life. The following maintenance practices are recommended:

7.1 Regular Inspections

Periodic visual inspections should be conducted to check for signs of wear or damage, such as cracks in the spider element, hub deformation, or loose fasteners. Inspections should be performed at least every six months (or more frequently for high-duty applications) and should include checking for excessive vibration, noise, or temperature buildup—all of which can indicate coupling failure.

7.2 Spider Element Replacement

The elastomeric spider element is the most wear-prone component of the coupling and will eventually degrade over time due to fatigue, temperature exposure, or chemical contact. Signs of spider wear include cracking, hardening, or softening of the material, as well as increased vibration or noise. The spider should be replaced immediately when these signs are detected. Replacement is a simple process for two-piece couplings: the hubs are separated slightly, the old spider is removed, and a new spider is inserted. It is important to use a spider element made from the correct material and size to ensure compatibility with the hubs.

7.3 Shaft Alignment Checks

While spider couplings accommodate misalignment, excessive or persistent misalignment can accelerate wear on the spider and other components. Regular shaft alignment checks (using laser alignment tools or dial indicators) are recommended to ensure that misalignment levels remain within the coupling’s limits. If misalignment exceeds acceptable levels, adjustments should be made to the connected equipment to correct the issue.

7.4 Lubrication (When Required)

Most standard spider couplings do not require lubrication, as the elastomeric spider element acts as a self-lubricating surface. However, hybrid spider couplings with gear elements may require periodic lubrication to reduce wear on the gear teeth. It is important to use the recommended lubricant type and follow the manufacturer’s guidelines for lubrication intervals.

7.5 Environmental Protection

In harsh environments (such as those with dust, debris, or chemicals), protective covers can be installed over the coupling to prevent contamination of the spider element and hubs. This helps to extend the life of the coupling and reduce the frequency of maintenance.

8. Conclusion

Spider couplings are a versatile and reliable solution for power transmission systems, offering a unique combination of flexibility, torque capacity, and ease of maintenance. Their ability to accommodate misalignment, dampen vibrations, and absorb shock loads makes them indispensable in a wide range of industries, from industrial manufacturing and automotive to robotics, aerospace, and mining. By understanding the fundamental principles, design variations, and selection criteria of spider couplings, engineers and maintenance professionals can select the optimal coupling for their specific application, ensuring efficient performance and extended equipment lifespan.

Proper maintenance practices—including regular inspections, timely spider replacement, and alignment checks—are critical to maximizing the performance and longevity of spider couplings. As mechanical systems continue to evolve, spider coupling designs are likely to advance further, with improvements in material technology (such as more durable elastomers and lightweight composites) and design optimization (such as enhanced misalignment capabilities and higher torque ratings). Regardless of these advancements, the core advantages of spider couplings—simplicity, flexibility, and cost-effectiveness—will ensure their continued role as a cornerstone of power transmission technology.

« Spider Couplings » Post Date: 2023/7/3

URL: http://www.rokee.com/en/tags/SpiderCouplings.html