Claw Couplings

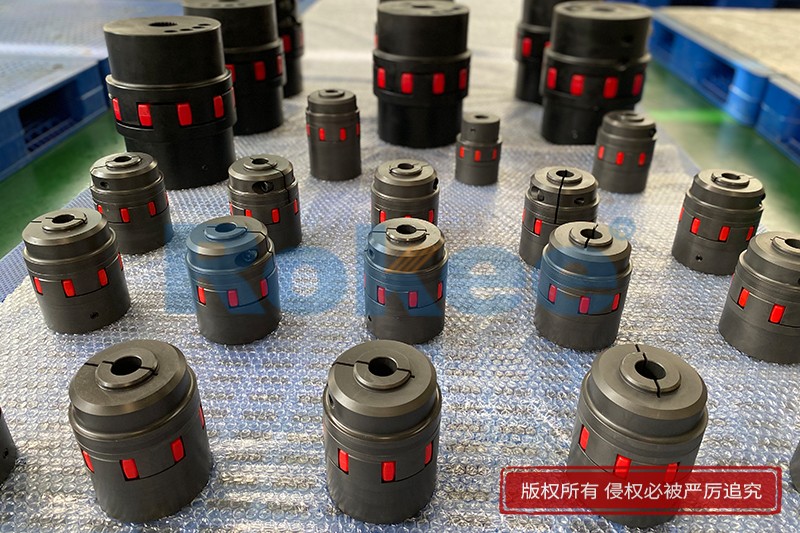

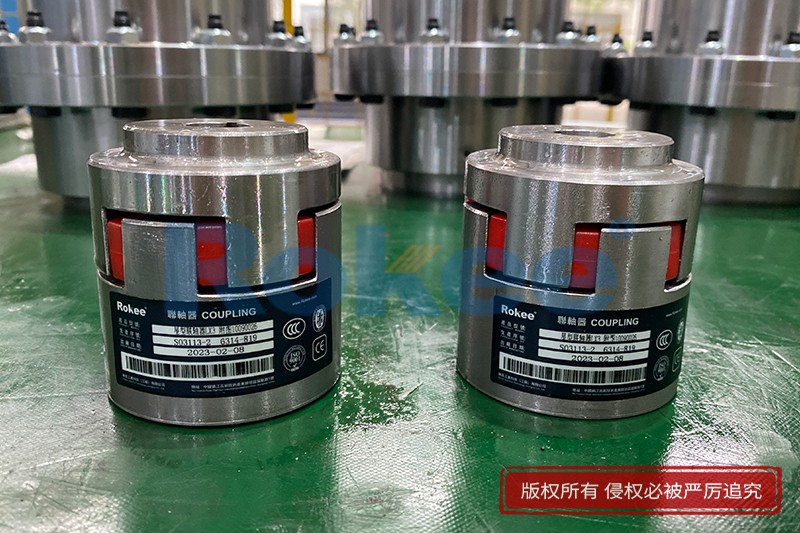

Rokee is Claw Couplings Manufacturer, Customizable according to the claw couplings drawings provided by the customer, Support Export.

The Claw Coupling is composed of two semi-couplings with convex claws and a plum-shaped flexible non-metallic element whose hardness can be adjusted. By embedding the plum-shaped flexible element into the two semi-couplings to realize the connection, Claw Coupling has the characteristics of compensating the relative displacement of the two axes, reducing vibration and buffering, simple structure and easy maintenance without lubrication.

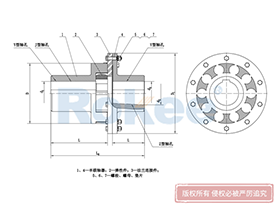

LM/ML Plum-shaped Flexible Coupling

Basic Type

LM Plum-shaped Flexible Coupling is the basic form of this series of couplings.View MoreLMD/MLZ Plum-shaped Flexible Coupling

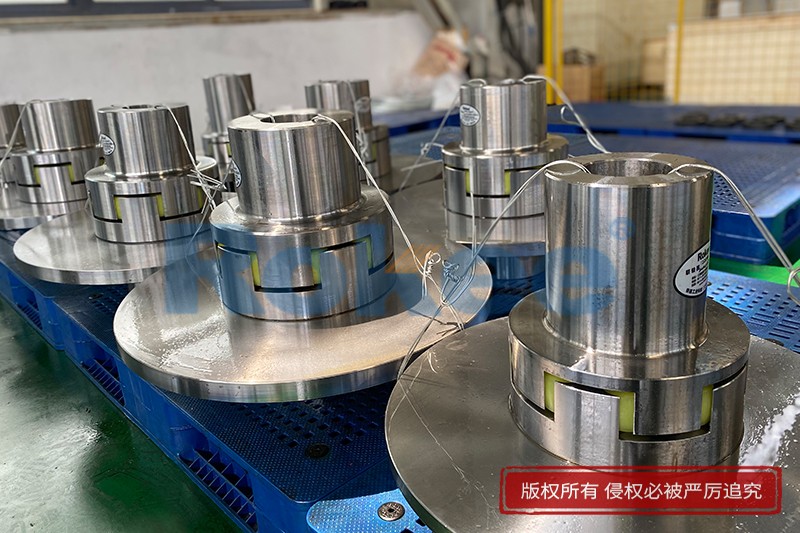

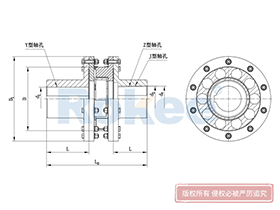

Single Flange

LMD Plum-shaped Flexible Coupling is added with transition connection, which eliminates the need of axially moving the semi-coupling when replacing the elastomer.View MoreLMS/MLS Plum-shaped Flexible Coupling

Double Flange

LMS Plum-shaped Flexible Coupling adopts double transition flange connection, which eliminates the need of axially moving the semi-coupling when replacing the elastomer.View MoreLMZ-I/MLL-I Plum-shaped Flexible Coupling

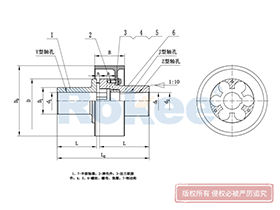

Split Type, With Brake Wheel

LMZ-I Plum-shaped Flexible Coupling adopts split brake wheel design, suitable for situations where braking is required.View MoreLMZ-II/MLL-II Plum-shaped Flexible Coupling

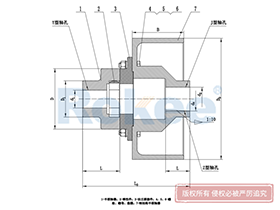

Integral, With Brake Wheel

LMZ- II Plum-shaped Flexible Coupling adopts integral brake wheel design, suitable for situations where braking is required.View MoreLMPK/MLPK Plum-shaped Flexible Coupling

Split Type, With Brake Discs

LMPK Plum-shaped Flexible Coupling adopts split brake disc design, suitable for situations where braking is required and eliminating the need of axially moving the semi-coupling when replacing the elastomer.View More

In the realm of mechanical power transmission, couplings serve as indispensable components that bridge rotating shafts, enabling the seamless transfer of torque while accommodating inevitable misalignments and mitigating operational stresses. Among the diverse array of coupling types available, claw couplings stand out for their unique combination of simplicity, versatility, and cost-effectiveness. Also known as jaw couplings, these mechanical devices have become a staple in numerous industrial and commercial applications, ranging from small-scale machinery to heavy-duty industrial systems.

1. Fundamental Structure and Working Principle of Claw Couplings

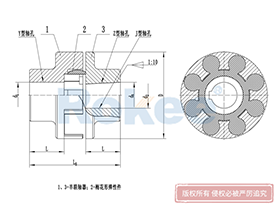

At its core, a claw coupling is characterized by a straightforward yet ingenious design that consists of three primary components: two metal claw discs (also referred to as semi-couplings) and a flexible non-metallic insert. The structural simplicity of this design is one of the key factors contributing to its widespread adoption, as it facilitates easy manufacturing, installation, and maintenance.

The two semi-couplings are typically fabricated from metal materials, each featuring a series of convex claws evenly distributed along their circumferential edges. These claws are precision-engineered to intermesh with the flexible insert, which is often shaped like a plum blossom—giving rise to another common name for this coupling type: plum blossom coupling. The flexible insert, made from elastomeric materials such as polyurethane, rubber, or engineering plastics, acts as the intermediary between the two semi-couplings, enabling torque transmission while providing the necessary flexibility to compensate for shaft misalignments

The working principle of a claw coupling revolves around the transfer of torque through the compression of the flexible insert. When torque is applied to one of the semi-couplings (e.g., from an electric motor), the convex claws of this semi-coupling exert compressive forces on the flexible insert. These forces are then transmitted to the claws of the second semi-coupling, causing it to rotate in synchronization with the first. This torque transmission mechanism is efficient and reliable, with minimal energy loss under normal operating conditions.

A critical function of the flexible insert is to compensate for three types of shaft misalignments that are common in mechanical systems: axial, radial, and angular misalignment. Axial misalignment occurs when the shafts are displaced along their central axes; radial misalignment refers to the offset of the shafts' central axes in a direction perpendicular to their rotation; and angular misalignment is the tilt between the two shafts. When such misalignments occur, the flexible insert undergoes elastic deformation to absorb the displacement, thereby preventing excessive stress on the shafts, bearings, and other components of the transmission system. Additionally, the elastomeric insert serves as a vibration damper and shock absorber, reducing the transmission of vibrations from one shaft to another and cushioning the impact of sudden load changes, which enhances the overall stability and longevity of the machinery

2. Material Selection for Claw Couplings

The performance, durability, and applicability of a claw coupling are heavily influenced by the choice of materials for its components. The selection of materials is guided by various factors, including the torque requirements, operating environment, temperature range, weight constraints, and corrosion resistance needs.

2.1 Materials for Semi-Couplings

The semi-couplings (claw discs) are primarily made from metal materials due to their need to withstand torque and maintain structural integrity. The most commonly used material for this purpose is medium carbon steel, such as 45# steel, which offers an excellent balance of strength, toughness, and machinability. This material is suitable for most general-purpose applications where moderate to high torque transmission is required

In applications where weight is a critical consideration, such as in lightweight machinery or high-speed systems, aluminum alloys are preferred. Aluminum alloys are significantly lighter than steel, reducing the moment of inertia of the coupling and minimizing the load on the bearings. They also exhibit good corrosion resistance, making them suitable for use in mild corrosive environments. However, aluminum alloys have lower tensile strength than steel, so they are typically used in low to medium torque applications

For harsh environments where corrosion resistance is paramount—such as in marine applications, chemical processing plants, or outdoor machinery—stainless steel or brass are ideal choices. Stainless steel offers exceptional resistance to rust and chemical corrosion, while brass provides good corrosion resistance and machinability. In extremely demanding environments involving high temperatures, high pressure, or aggressive chemicals, more advanced materials like titanium may be used, although this is relatively rare due to the high cost

In some low-torque, low-cost applications, engineering plastics may also be used for the semi-couplings. These materials are lightweight, corrosion-resistant, and cost-effective, but their load-bearing capacity is limited, restricting their use to light-duty machinery

2.2 Materials for Flexible Inserts

The flexible insert is the most critical component in terms of material selection, as it directly affects the coupling's flexibility, vibration damping capacity, temperature resistance, and service life. The most commonly used materials for flexible inserts include polyurethane, rubber, and engineering plastics such as polyacetal and nylon

Polyurethane is a popular choice due to its excellent combination of elasticity, wear resistance, and load-bearing capacity. It is available in various hardness ratings (measured on the Shore A scale, typically ranging from 80 to 98 Shore A), allowing for customization based on the specific requirements of the application. Higher hardness polyurethane inserts offer greater torsional stiffness and torque capacity, while lower hardness inserts provide better vibration damping and flexibility

Rubber inserts are known for their superior vibration damping properties and flexibility, making them suitable for applications with high levels of vibration or shock loads. However, rubber has lower wear resistance than polyurethane and may degrade over time when exposed to high temperatures, oils, or chemicals. Common types of rubber used include natural rubber, nitrile rubber, and neoprene, each with specific properties tailored to different operating conditions

Engineering plastics such as polyacetal and nylon are used in applications where high wear resistance and dimensional stability are required. These materials offer good chemical resistance and can operate in a wider temperature range than some rubbers. However, they have lower elasticity than rubber and polyurethane, which limits their misalignment compensation capability

3. Types of Claw Couplings

Claw couplings are available in a variety of designs to accommodate different application requirements, including torque capacity, installation conditions, maintenance needs, and operating environment. The main types of claw couplings can be categorized based on their structural features and insert configurations

3.1 Based on Insert Configuration

The number of lobes (or claws) on the flexible insert is a key distinguishing feature. Common configurations include four-lobe, six-lobe, eight-lobe, and ten-lobe inserts. The number of lobes affects the coupling's torque capacity, flexibility, and vibration damping performance. Couplings with more lobes distribute the torque more evenly across the insert, reducing stress concentration and improving durability. They also offer better angular misalignment compensation. However, couplings with fewer lobes tend to have higher torsional stiffness, making them suitable for applications requiring precise torque transmission

3.2 Based on Structural Design

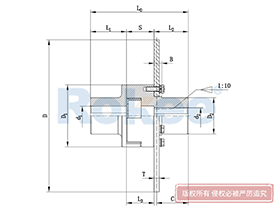

1. Basic Type (LM Series): This is the simplest form of claw coupling, consisting of two semi-couplings and a plum-shaped flexible insert. It is widely used in general-purpose applications where moderate torque transmission and misalignment compensation are required. The basic type is easy to install and maintain, but replacing the flexible insert requires axial movement of the semi-couplings

2. Single Flange Type (LMD Series): This type incorporates a transition flange, which eliminates the need for axial movement of the semi-couplings when replacing the flexible insert. This design simplifies maintenance, making it suitable for applications where space is limited or where frequent insert replacement is anticipated

3. Double Flange Type (LMS Series): Featuring double transition flanges, this type further enhances the ease of maintenance. The double flange design allows for quick and easy replacement of the flexible insert without disturbing the shaft alignment, making it ideal for critical applications where downtime must be minimized

4. Split Type with Brake Wheel (LMZ-I Series): This design includes a split brake wheel, which is suitable for applications requiring braking functionality. The split design allows for easy installation and removal of the brake wheel without disassembling the coupling or shafts

5. Integral Type with Brake Wheel (LMZ-II Series): Similar to the split type, but with an integral brake wheel for applications requiring higher braking torque and structural integrity. The integral design provides greater stability but is more complex to install and maintain

6. Split Type with Brake Disc (LM PK Series): This type uses a split brake disc instead of a brake wheel, making it suitable for applications requiring precise braking control. The split design facilitates easy maintenance, and the brake disc offers better heat dissipation than a brake wheel

3.3 Based on Claw Shape

1. C-Style Claw Couplings: The claws are shaped like the letter "C", providing a strong grip when intermeshed with the insert. This type is easy to connect and disconnect with a simple quarter turn, making it practical for applications requiring frequent maintenance or equipment swapping. C-style couplings are commonly used in industrial settings with pumps, compressors, and other heavy-duty machinery

2. S-Style Claw Couplings: The S-shaped claws offer enhanced flexibility, making them suitable for applications where shaft misalignment may occur due to vibration, temperature changes, or thermal expansion. They are widely used in the automotive and aviation industries, where precise alignment is challenging under dynamic operating conditions

3. A-Style Claw Couplings: This is a simple, cost-effective design suitable for low-power applications. A-style couplings have a lightweight construction and are easy to install, making them ideal for general-purpose machinery with low torque requirements

4. Q-Style Claw Couplings: A relatively new design with wider claws that provide better contact with the insert, distributing the load more evenly. This results in improved durability and torque capacity, making Q-style couplings suitable for high-torque applications and harsh environments where wear and tear are significant concerns

4. Key Characteristics and Advantages of Claw Couplings

Claw couplings offer a range of characteristics and advantages that make them a preferred choice in many mechanical systems. These include:

1. Compact Structure: Claw couplings have a small radial size and short overall length, making them suitable for applications with limited installation space. Their lightweight design also reduces the moment of inertia, which is beneficial for high-speed applications

2. Excellent Misalignment Compensation: As mentioned earlier, claw couplings can effectively compensate for axial, radial, and angular misalignments, reducing stress on shafts, bearings, and other components. This capability is crucial in mechanical systems where perfect alignment is difficult to achieve or maintain

3. Vibration Damping and Shock Absorption: The flexible insert absorbs vibrations and cushions shock loads, minimizing the transmission of vibrations to other parts of the machinery. This not only improves the stability and performance of the system but also extends the service life of the equipment

4. Maintenance-Free Operation: Most claw couplings do not require lubrication, as the flexible insert acts as a self-lubricating component. This eliminates the need for regular lubrication maintenance, reducing downtime and operational costs. Additionally, the simple design facilitates easy replacement of the flexible insert when necessary

5. Electrical Insulation: The non-metallic flexible insert provides electrical insulation between the two semi-couplings, preventing the flow of electric current between the shafts. This is a critical safety feature in applications where electrical isolation is required, such as in some motor-driven systems

6. Cost-Effectiveness: Claw couplings are relatively inexpensive to manufacture compared to other types of couplings, such as diaphragm couplings or gear couplings. Their low maintenance costs and long service life further enhance their cost-effectiveness

5. Applications of Claw Couplings

Due to their versatile performance and cost-effectiveness, claw couplings find applications in a wide range of industries and machinery types. Some of the key application areas include:

5.1 Industrial Machinery

Claw couplings are extensively used in various industrial machinery, including metallurgy, mining, petroleum, and chemical processing equipment. In the metallurgy industry, they are used to connect motors to rolling mills, conveyors, and other heavy-duty machinery. In the mining industry, they are employed in pumps, compressors, and crushers, where they must withstand high torque and harsh operating conditions. In the petroleum and chemical industries, corrosion-resistant claw couplings (made from stainless steel or brass) are used to connect pumps, mixers, and agitators, ensuring reliable operation in corrosive environments

5.2 General Machinery and Equipment

In general machinery, claw couplings are used in a variety of applications, such as water pumps, fans, blowers, and air compressors. These applications require efficient torque transmission, vibration damping, and easy maintenance, which claw couplings provide. For example, in water treatment plants, claw couplings connect electric motors to water pumps, ensuring the reliable transfer of water while compensating for any misalignments between the motor and pump shafts

5.3 Transportation and Automotive Industry

In the transportation and automotive industry, claw couplings are used in various components, such as gearboxes, axle drives, and hydraulic drives. S-style claw couplings are particularly suitable for automotive applications, where they can accommodate misalignments caused by vibration and thermal expansion. They are also used in railway systems, connecting motors to conveyors and other auxiliary equipment

5.4 Machine Tools

Machine tools, such as lathes, milling machines, and machining centers, require precise torque transmission and low vibration to ensure machining accuracy. Claw couplings with polyurethane inserts are often used in these applications, as they offer high torsional stiffness and good vibration damping. They are used to connect the motor to the spindle or feed axes, ensuring smooth and precise operation

5.5 Light Industry and Textile Machinery

In the light industry, including textile, packaging, and food processing machinery, claw couplings are used in conveyors, positioning systems, and filling lines. These applications require low noise, smooth operation, and easy maintenance, which claw couplings provide. For example, in textile mills, claw couplings connect motors to textile machines such as looms and spinning frames, ensuring consistent performance and minimizing downtime

5.6 Renewable Energy Systems

Claw couplings are also finding increasing applications in renewable energy systems, such as wind turbines and solar power plants. In wind turbines, they are used to connect the generator to the gearbox, compensating for misalignments and damping vibrations. The maintenance-free operation of claw couplings is particularly beneficial in wind turbines, which are often located in remote areas and require minimal downtime

6. Selection Criteria for Claw Couplings

Selecting the right claw coupling for a specific application is crucial to ensure optimal performance, reliability, and longevity. The following factors should be considered during the selection process:

6.1 Torque Requirement

The primary factor to consider is the torque that the coupling must transmit. The nominal torque of the coupling should be greater than or equal to the maximum torque generated by the driving device (e.g., motor). It is important to account for peak torques caused by sudden load changes or startup conditions, as these can exceed the normal operating torque. Selecting a coupling with insufficient torque capacity can lead to premature failure

6.2 Shaft Misalignment

The type and magnitude of shaft misalignment should be carefully evaluated. Different types of claw couplings have varying misalignment compensation capabilities. For example, couplings with more lobes or S-shaped claws offer better angular and radial misalignment compensation. It is important to select a coupling that can accommodate the maximum expected misalignment in the system

6.3 Operating Speed

The maximum operating speed of the coupling should be compatible with the rotational speed of the shafts. High-speed applications require couplings with low moment of inertia to minimize centrifugal forces. Aluminum alloy semi-couplings are preferred for high-speed applications due to their lightweight construction. It is also important to ensure that the flexible insert can withstand the centrifugal forces at high speeds without deforming or failing

6.4 Operating Environment

The operating environment has a significant impact on the material selection and performance of the coupling. Factors such as temperature, humidity, corrosion, and exposure to chemicals or oils should be considered. For high-temperature environments, flexible inserts made from high-temperature-resistant materials such as silicone rubber or polyurethane should be used. For corrosive environments, stainless steel or brass semi-couplings are recommended

6.5 Installation and Maintenance

The installation space and maintenance requirements should also be considered. In applications with limited space, compact couplings such as the basic type or single flange type are suitable. For applications requiring frequent maintenance, couplings with easy-to-replace inserts (such as the single flange or double flange type) are preferred

6.6 Cost and Budget

While cost should not be the sole determining factor, it is an important consideration. Claw couplings are generally cost-effective, but the price varies depending on the material, design, and torque capacity. It is important to balance performance requirements with budget constraints to select the most cost-effective solution

7. Installation and Maintenance Guidelines

Proper installation and maintenance are essential to ensure the optimal performance and longevity of claw couplings.

7.1 Installation Guidelines

1. Before installation, inspect the coupling components for any damage or defects. Ensure that the semi-couplings, flexible insert, and fasteners are in good condition

2. Clean the shaft surfaces to remove any dirt, rust, or debris. This ensures a secure fit between the semi-couplings and the shafts

3. Install the semi-couplings on the respective shafts, ensuring that they are properly aligned. The alignment should be checked using a dial indicator or laser alignment tool to minimize initial misalignment

4. Insert the flexible insert into the claws of one semi-coupling, then carefully align the other semi-coupling with the insert and secure it in place using the appropriate fasteners. Ensure that the fasteners are tightened to the recommended torque

5. After installation, manually rotate the shafts to check for smooth operation. There should be no binding or excessive resistance

7.2 Maintenance Guidelines

1. Regularly inspect the coupling for signs of wear, damage, or deterioration. Pay particular attention to the flexible insert, which is the most susceptible component to wear. Look for cracks, tears, or hardening of the insert

2. Check the tightness of the fasteners periodically. Loose fasteners can cause misalignment and excessive vibration

3. Replace the flexible insert when signs of wear or damage are detected. The replacement process should be carried out according to the manufacturer's instructions. For couplings with flanged designs, the insert can be replaced without removing the semi-couplings from the shafts

4. In corrosive environments, regularly clean the semi-couplings to remove any corrosive substances. This helps to prevent corrosion and extend the service life of the coupling

5. Avoid overloading the coupling beyond its nominal torque capacity. Overloading can lead to premature failure of the flexible insert or semi-couplings

8. Comparison with Other Coupling Types

To better understand the position of claw couplings in the broader spectrum of coupling types, it is useful to compare them with other commonly used couplings, such as diaphragm couplings and gear couplings.

8.1 Claw Couplings vs. Diaphragm Couplings

Diaphragm couplings consist of one or more diaphragms installed between two connecting bodies, typically made from stainless steel or spring steel. Unlike claw couplings, diaphragm couplings are rigid in the rotational direction but flexible in the axial direction. They offer high precision and are suitable for high-speed, high-power applications where rotational accuracy is critical. However, diaphragm couplings have lower misalignment compensation capabilities than claw couplings, particularly in the radial and angular directions. They are also more expensive and require more precise installation. Claw couplings, on the other hand, are more cost-effective, offer better vibration damping, and are easier to maintain, making them suitable for general-purpose applications

8.2 Claw Couplings vs. Gear Couplings

Gear couplings use gear teeth to transmit torque between two shafts. They offer high torque capacity and are suitable for heavy-duty applications. However, gear couplings require regular lubrication and have complex maintenance requirements. They also have limited vibration damping capabilities and are more expensive than claw couplings. Claw couplings are preferred for applications where maintenance is a concern and where vibration damping is required. They are also more suitable for medium to low torque applications, while gear couplings are better for high torque applications

9. Conclusion

Claw couplings are versatile, cost-effective, and reliable components that play a crucial role in mechanical power transmission systems. Their simple design, excellent misalignment compensation, vibration damping capabilities, and maintenance-free operation make them a preferred choice in a wide range of industries, from general machinery to heavy-duty industrial applications. The selection of the right claw coupling depends on various factors, including torque requirements, shaft misalignment, operating speed, environment, and maintenance needs. By carefully considering these factors and following proper installation and maintenance guidelines, the performance and longevity of claw couplings can be maximized, ensuring the smooth and efficient operation of the machinery they serve.

As mechanical systems continue to evolve, the design and materials of claw couplings are also likely to advance, further enhancing their performance and expanding their application range. Future developments may focus on improving the high-temperature resistance and wear resistance of flexible inserts, as well as developing more compact and lightweight designs to meet the needs of emerging technologies such as electric vehicles and advanced manufacturing systems. Regardless of these advancements, the fundamental advantages of claw couplings—simplicity, versatility, and cost-effectiveness—will ensure their continued relevance in the field of mechanical power transmission.

« Claw Couplings » Post Date: 2023/10/9

URL: http://www.rokee.com/en/tags/claw-couplings.html