Pin Couplings

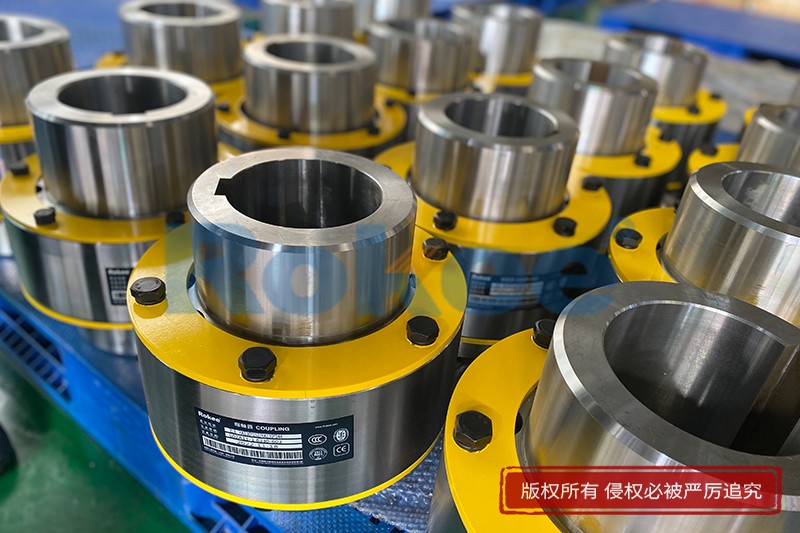

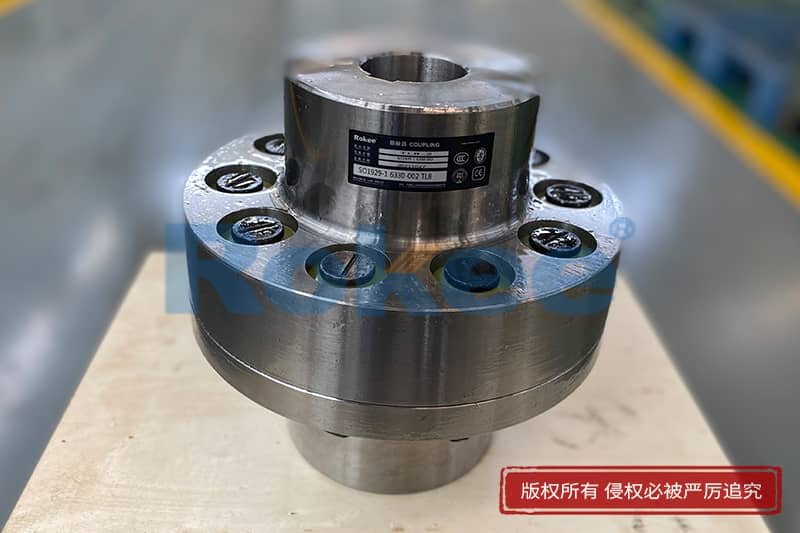

Rokee is Pin Couplings Manufacturer, Customizable according to the pin couplings drawings provided by the customer, Support Export.

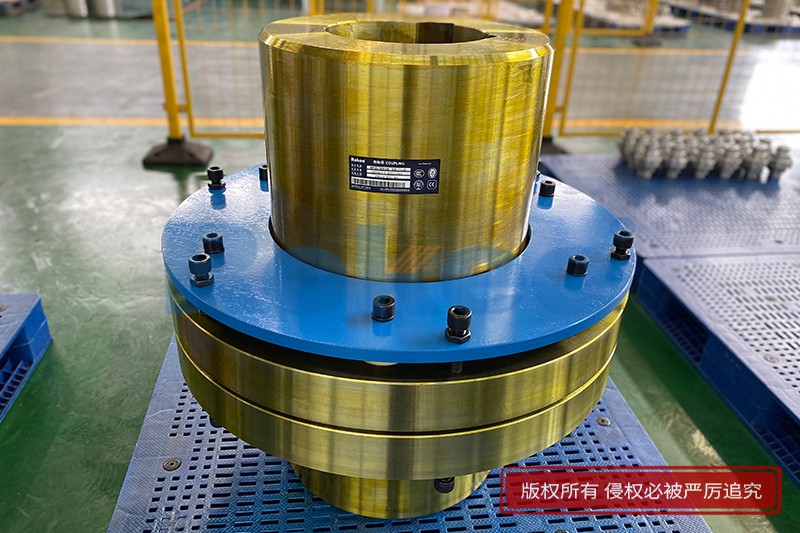

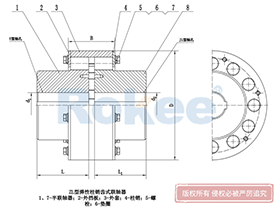

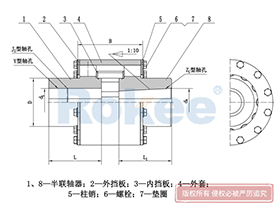

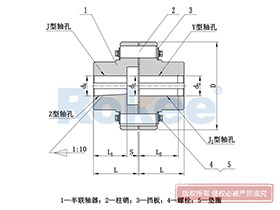

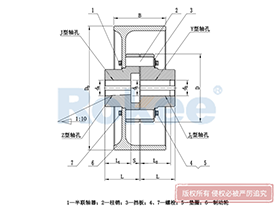

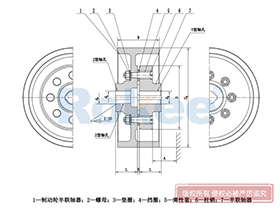

The gear pin couplings is designed with non-metallic flexible pin, two toothed semi-couplings and a toothed sleeve ring with an outer ring. It uses non-metallic flexible deformation to transfer torque and cushion shock and compensate angular displacement.

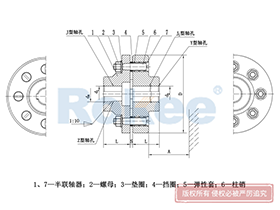

The flexible pin coupling is a basic transmission parts that has simple structure, needs no lubrication, and is easy to manufacture, install and disassemble the flexible pin. It uses two semi-couplings with flange holes and a non-metallic flexible pin for crane to transmit torque, suitable for low-to-medium speed and low-to-medium torque occasions.

The design of the elastic sleeve pin coupling is simple and clever in design and has wide applicability. It uses the pin with elastic sleeve to connect two semi-couplings with pin holes to realize torque transmission and larger angular compensation. At the same time, it has good shock absorption and buffering performance, which can be used in high-speed occasions without lubrication and requiring easy pin sleeve replacement.

LZ/ZL Pin Gear Coupling

Basic Type

LZ Pin Gear Coupling is the basic form of this series of couplings.View MoreLZD/ZLD Pin Gear Coupling

Conical Shaft Hole

One end of the LZD Pin Gear Coupling is designed with a conical shaft hole, and the clearance between the semi-couplings is increased to facilitate the fixing space at the shaft end.View MoreLZZ/ZLL Pin Gear Coupling

With Brake Wheel

LZZ Pin Gear Coupling is designed with a brake wheel, suitable for situations where braking is required.View MoreLX/HL Flexible Pin Coupling

Basic Type

LX(HL) Flexible Pin Coupling is the basic form of this series of couplings.View MoreLXZ/HLL Flexible Pin Coupling

With Brake Wheel

LXZ(HLL) Flexible Pin Coupling is designed with a brake wheel, suitable for situations where braking is required.View MoreLT/TL Elastic Sleeve Pin Coupling

Basic Type

LT Elastic Sleeve Pin Coupling is the basic form of this series of couplings.View MoreLTZ/TLL Elastic Sleeve Pin Coupling

With Brake Wheel

LTZ Elastic Sleeve Pin Coupling is designed with a brake wheel, suitable for situations where braking is required.View More

In the realm of mechanical power transmission, couplings serve as the critical link between rotating shafts, enabling the seamless transfer of torque while accommodating inevitable misalignments and mitigating operational stresses. Among the diverse array of coupling technologies available, pin couplings stand out for their simplicity, cost-effectiveness, and versatility. Designed to balance performance and practicality, these couplings have become a staple in numerous industrial, agricultural, and marine applications, where reliable power transmission under varying load conditions is paramount.

1. Understanding Pin Couplings: Definition and Core Functionality

A pin coupling, also referred to as a flexible pin coupling in its most common form, is a mechanical component engineered to connect two coaxial rotating shafts in power transmission systems. Its primary function is to transmit torque from a driving shaft (e.g., from an electric motor or engine) to a driven shaft (e.g., of a pump, compressor, or conveyor), while simultaneously compensating for minor shaft misalignments—including angular, radial, and axial misalignment—and dampening shock loads and vibrations generated during operation. Unlike rigid couplings, which require near-perfect shaft alignment and offer no flexibility, pin couplings incorporate design elements that allow for a degree of movement, thereby protecting both the coupling itself and the connected machinery from premature wear and failure.

The core functionality of a pin coupling revolves around the interaction between its key components: two hubs (or flanges) and a series of pins (often with associated flexible elements). Each hub is attached to one of the shafts via keyways, set screws, or other fastening mechanisms, ensuring a secure connection that prevents slippage during rotation. The pins, which can be rigid or flexible, are inserted into corresponding holes or slots in both hubs, creating a mechanical link that transfers torque. In flexible designs, elastomeric bushes or sleeves are placed around the pins, enhancing the coupling’s ability to absorb shocks and vibrations and increasing its capacity to accommodate misalignment. This combination of simplicity and flexibility makes pin couplings suitable for a broad spectrum of operating conditions, from light-duty to heavy-duty applications.

2. Design Variations of Pin Couplings

Pin couplings are available in several distinct configurations, each tailored to specific operational requirements such as torque capacity, misalignment tolerance, speed, and environmental conditions. The primary design variations are distinguished by the number of pins, the presence of flexible elements, and the overall structure of the coupling. Below are the most common types:

2.1 Rigid Pin Couplings

Rigid pin couplings represent the simplest form of pin coupling design. They consist of two solid hubs and a single pin or multiple rigid pins that directly connect the hubs without any flexible intermediaries. This design offers high torque transmission capacity and structural rigidity but has limited tolerance for shaft misalignment. As a result, rigid pin couplings are typically used in applications where shaft alignment can be maintained with high precision, such as small-scale machinery with low operating speeds and minimal vibration. However, their lack of flexibility makes them less suitable for applications with frequent start-stop cycles or shock loads, as these conditions can lead to excessive stress on the pins and hubs.

2.2 Elastic Sleeve Pin Couplings

Elastic sleeve pin couplings (also known as elastic pin couplings with sleeves) are the most widely used type of pin coupling due to their excellent balance of flexibility, torque capacity, and ease of maintenance. This design incorporates pins that are surrounded by elastomeric sleeves (usually made of rubber, polyurethane, or nylon) before being inserted into the hub holes. The elastomeric sleeves act as a buffer, absorbing shock loads and vibrations, reducing noise during operation, and accommodating greater levels of angular and radial misalignment compared to rigid pin couplings.

A key advantage of elastic sleeve pin couplings is their simplicity of assembly and disassembly. The elastomeric sleeves can be easily replaced without moving the connected shafts, minimizing downtime for maintenance. This design is suitable for medium-speed, medium-torque applications, such as pumps, fans, compressors, and agricultural machinery. The working temperature range of these couplings is typically between -20°C and 80°C, depending on the material of the elastomeric sleeves, making them adaptable to most industrial environments.

2.3 Flexible Pin Couplings with Non-Metallic Pins

In this variation, the pins themselves are made of non-metallic, flexible materials such as nylon or reinforced plastic, eliminating the need for separate elastomeric sleeves. The non-metallic pins transmit torque through their shear strength while providing flexibility to compensate for misalignment and dampen vibrations. This design is characterized by its simplicity, low cost, and minimal maintenance requirements, as it does not require lubrication. However, non-metallic pins have lower torque capacity and may degrade more quickly under high temperatures or harsh chemical environments compared to metallic pins with elastomeric sleeves. As a result, this type of coupling is commonly used in light-duty to medium-duty applications, such as small electric motors, conveyors, and laboratory equipment.

2.4 Pin Gear Couplings

Pin gear couplings represent a more robust variation of pin couplings, designed for heavy-duty applications requiring high torque transmission and enhanced misalignment compensation. This design features two toothed semi-couplings and a toothed sleeve ring with an outer ring, along with non-metallic flexible pins. The toothed structure ensures even load distribution across the pins, while the non-metallic pins provide flexibility through elastic deformation. Pin gear couplings can accommodate larger angular displacements and higher torque loads than standard elastic sleeve pin couplings, making them suitable for heavy industrial machinery such as crushers, rolling mills, and marine propulsion systems.

2.5 Spiral Pin Couplings

Spiral pin couplings feature a helical (spiral) arrangement of elastomeric pins, which enhances their flexibility and energy absorption capabilities under dynamic loads. The spiral design allows for more even load distribution across the pins, reducing stress concentrations and extending the coupling’s service life. This type of coupling is particularly well-suited for applications with frequent start-stop cycles, high vibration levels, or variable torque loads, such as compressors, conveyors, and heavy industrial drives. However, spiral pin couplings have limited tolerance for angular misalignment and may require more precise installation compared to other pin coupling variations.

3. Material Selection for Pin Couplings

The performance and durability of a pin coupling are heavily influenced by the materials used for its components. Material selection is determined by a range of factors, including the application’s torque requirements, operating speed, temperature, environmental conditions (e.g., presence of moisture, chemicals, or dust), and desired service life. Below is an overview of the most common materials used for the key components of pin couplings:

3.1 Hub Materials

The hubs of pin couplings are typically made of metallic materials due to their need for high structural strength and wear resistance. The most common hub materials include:

- Cast Iron: Cast iron is a cost-effective material with good machinability and wear resistance. It is suitable for light-duty to medium-duty applications with moderate torque requirements, such as small pumps and fans. However, cast iron is brittle and may crack under excessive shock loads.

- Carbon Steel (e.g., C45 Steel): Carbon steel offers higher tensile strength and torque capacity than cast iron, making it suitable for medium-duty to heavy-duty applications. It is machinable and can be heat-treated to enhance its hardness and wear resistance. Carbon steel hubs are commonly used in industrial machinery such as compressors, conveyors, and generators.

- Alloy Steel: Alloy steel (e.g., chromium-molybdenum steel) provides superior strength, durability, and resistance to fatigue and high temperatures. This material is used in heavy-duty applications with high torque loads and harsh operating conditions, such as marine propulsion systems, rolling mills, and mining equipment.

- Aluminum: Aluminum is lightweight and corrosion-resistant, making it suitable for applications where weight is a critical factor, such as aerospace components or small, portable machinery. However, aluminum has lower torque capacity than steel or cast iron, limiting its use to light-duty applications.

3.2 Pin and Flexible Element Materials

The materials used for the pins and flexible elements (sleeves or bushes) are selected based on their flexibility, shear strength, and resistance to wear and environmental factors:

- Metallic Pins: Metallic pins are typically made of carbon steel or alloy steel for high torque capacity and strength. They are used in rigid pin couplings and elastic sleeve pin couplings, where the elastomeric sleeve provides flexibility.

- Non-Metallic Pins: Non-metallic pins are made of materials such as nylon (e.g., Nylon 6), polyurethane, or reinforced plastic. These materials offer inherent flexibility, shock absorption, and corrosion resistance. Nylon pins are particularly popular due to their high shear strength and low cost, but they may soften at high temperatures.

- Elastomeric Sleeves/Bushes: Elastomeric sleeves are commonly made of rubber, polyurethane, or silicone. Rubber sleeves offer excellent vibration dampening and flexibility but may degrade under exposure to oils or chemicals. Polyurethane sleeves have higher wear resistance and tensile strength than rubber, making them suitable for more demanding applications. Silicone sleeves are resistant to high temperatures and chemicals, making them ideal for harsh environmental conditions.

4. Working Principle of Pin Couplings

The working principle of a pin coupling is based on the transfer of torque through the mechanical interaction between the pins and the hubs, with flexibility provided by either the pins themselves or associated elastomeric elements. The process can be broken down into the following key steps:

1. Connection: Each hub is securely attached to the respective driving and driven shafts. This is typically achieved using keyways and set screws, which ensure that the hubs rotate in synchrony with the shafts without slippage.

2. Torque Transmission: When the driving shaft rotates, it imparts rotational force to the attached hub. This force is transferred to the pins, which are inserted into the hub holes. The pins then transmit the torque to the second hub, causing the driven shaft to rotate.

3. Misalignment Compensation: In flexible pin coupling designs, the elastomeric sleeves or non-metallic pins deform elastically to accommodate minor shaft misalignments. For example, angular misalignment (where the shafts are not colinear) is compensated by the bending of the elastomeric sleeves, while radial misalignment (where the shafts are offset parallel to each other) is accommodated by the radial movement of the pins within the hub holes. Axial misalignment (where the shafts move along their axial direction) is accommodated by the compression or extension of the flexible elements.

4. Shock and Vibration Dampening: During operation, the elastomeric elements or non-metallic pins absorb shock loads (e.g., from sudden start-stop cycles) and vibrations by converting kinetic energy into heat, which is dissipated. This dampening effect reduces the stress on the connected machinery, extending its service life and improving operational stability.

It is important to note that the torque transmission capacity of a pin coupling is determined by the number and size of the pins, the material of the pins and hubs, and the design of the connection between the pins and hubs. Overloading a pin coupling can lead to shearing of the pins or damage to the hubs, resulting in catastrophic failure of the power transmission system.

5. Advantages and Limitations of Pin Couplings

Pin couplings offer a range of advantages that make them a popular choice in many industrial applications, but they also have certain limitations that must be considered during the selection process. Understanding these pros and cons is critical to ensuring that the coupling is suitable for the specific application requirements.

5.1 Advantages

- Simple Design and Easy Installation: Pin couplings have a straightforward structure with minimal components, making them easy to design, manufacture, assemble, and disassemble. This simplicity reduces installation time and labor costs, and allows for quick maintenance or replacement of components without the need for specialized tools.

- Cost-Effectiveness: Compared to other types of flexible couplings (such as disc couplings or gear couplings), pin couplings are generally more affordable to manufacture and purchase. This cost advantage makes them an attractive option for budget-constrained applications or large-scale industrial projects that require multiple couplings.

- Good Torque Transmission Capacity: Depending on the design and material selection, pin couplings can transmit a wide range of torque loads, from light-duty to heavy-duty applications. Rigid and pin gear variations, in particular, offer high torque capacity, making them suitable for large industrial machinery.

- Effective Shock and Vibration Dampening: Flexible pin coupling designs (with elastomeric sleeves or non-metallic pins) excel at absorbing shock loads and dampening vibrations, protecting the connected shafts and machinery from excessive stress. This feature is particularly beneficial in applications with frequent start-stop cycles or variable load conditions.

- Misalignment Compensation: The flexibility of pin couplings allows them to accommodate minor angular, radial, and axial misalignments between shafts. This reduces the need for precise shaft alignment during installation, which can be time-consuming and costly, and minimizes wear on bearing components.

- Low Maintenance Requirements: Most pin couplings do not require lubrication, reducing the frequency and cost of maintenance. Additionally, worn components (such as elastomeric sleeves or non-metallic pins) can be easily replaced, minimizing downtime for repairs.

- Versatility: Pin couplings are available in a wide range of sizes, designs, and materials, making them suitable for diverse applications across industries such as manufacturing, agriculture, construction, marine, and power generation.

5.2 Limitations

- Limited Precision: Pin couplings are not suitable for high-precision applications where minimal rotational backlash or exact torque transmission is required. The flexibility of the design can result in slight variations in rotational speed, making them unsuitable for machinery such as precision lathes or robotic systems.

- Limited Misalignment Tolerance: While pin couplings can accommodate minor misalignments, they have lower tolerance for large misalignments compared to other flexible couplings (such as universal joints or disc couplings). Exceeding the maximum allowable misalignment can lead to premature wear of the pins and hubs, reducing the coupling’s service life.

- Wear of Flexible Components: Elastomeric sleeves and non-metallic pins are subject to wear over time, especially under high temperatures, harsh chemical environments, or heavy loads. This requires regular inspection and replacement of these components to maintain the coupling’s performance.

- Noise Generation: Under high-speed or high-load conditions, pin couplings may generate noise due to the movement of the pins within the hub holes or the deformation of the elastomeric elements. This can be a disadvantage in applications where noise levels must be kept to a minimum, such as laboratory equipment or indoor manufacturing facilities.

- Limited Axial Load Capacity: Most pin couplings are not designed to handle large axial loads (loads parallel to the shaft axis). Excessive axial loads can cause the pins to bend or the hubs to shift, leading to coupling failure.

- Material Limitations: Non-metallic components (such as nylon pins or rubber sleeves) can degrade under extreme temperatures, exposure to oils, chemicals, or ultraviolet (UV) radiation. This limits the use of pin couplings in harsh environmental conditions unless specialized materials are used.

6. Industrial Applications of Pin Couplings

The versatility, cost-effectiveness, and reliability of pin couplings make them suitable for a wide range of industrial, commercial, and agricultural applications. Their ability to transmit torque, accommodate misalignment, and dampen vibrations makes them ideal for use in machinery with varying operating conditions. Below are some of the key application areas:

6.1 Manufacturing and Industrial Machinery

Pin couplings are extensively used in manufacturing facilities for connecting motors to a variety of machinery, including pumps, fans, compressors, conveyors, and mixers. Elastic sleeve pin couplings are particularly common in these applications due to their ability to handle medium speeds and torques while reducing vibration and noise. For example, in a conveyor system, a pin coupling connects the electric motor to the conveyor drive shaft, ensuring smooth power transmission even if there is minor misalignment between the shafts.

6.2 Agricultural Machinery

Agricultural equipment such as tractors, harvesters, and irrigation pumps often operate in harsh, dusty environments with frequent shock loads and variable torque requirements. Pin couplings are well-suited for these applications due to their rugged design, easy maintenance, and ability to dampen vibrations. For instance, a flexible pin coupling may be used to connect the engine of a tractor to its transmission system, ensuring reliable power transfer even when the tractor is operating on uneven terrain.

6.3 Construction Equipment

Construction machinery such as excavators, bulldozers, and concrete mixers requires robust power transmission systems that can handle high torque loads and shock impacts. Pin gear couplings and rigid pin couplings are commonly used in these applications due to their high torque capacity and structural strength. For example, a pin gear coupling may connect the engine of an excavator to its hydraulic pump, ensuring efficient power transmission even under heavy loads.

6.4 Marine Propulsion Systems

In marine applications, pin couplings are used to connect the engine of a ship or boat to its propeller shaft. The harsh marine environment (high humidity, saltwater exposure) requires couplings made of corrosion-resistant materials such as alloy steel or aluminum. Pin gear couplings are often preferred in this sector due to their ability to accommodate misalignment caused by the movement of the ship and their high torque transmission capacity.

6.5 Power Generation Equipment

Power generation facilities, including thermal power plants, hydroelectric plants, and wind farms, use pin couplings to connect turbines, generators, and other auxiliary equipment. Elastic sleeve pin couplings are used in medium-speed applications such as pumps and fans, while pin gear couplings are used in heavy-duty applications such as connecting turbines to generators. The vibration dampening properties of pin couplings help to protect sensitive electrical components in generators, ensuring reliable power output.

6.6 Laboratory and Medical Equipment

In laboratory settings, pin couplings are used in equipment such as shakers, centrifuges, and small pumps, where precision torque transmission and low vibration are critical. Flexible pin couplings with non-metallic pins are preferred in these applications due to their quiet operation and ability to minimize vibration, which helps to protect delicate samples and equipment.

7. Selection and Maintenance Best Practices

To ensure optimal performance and longevity of pin couplings, it is essential to follow best practices for selection and maintenance. Proper selection ensures that the coupling is matched to the application’s requirements, while regular maintenance prevents premature failure and minimizes downtime.

7.1 Selection Criteria

When selecting a pin coupling, the following factors should be carefully considered:

- Torque Requirements: The coupling must be capable of transmitting the maximum torque generated by the driving shaft without exceeding its rated capacity. It is recommended to select a coupling with a torque rating that is 10-20% higher than the maximum operating torque to account for shock loads and variable conditions.

- Shaft Misalignment: The type of misalignment (angular, radial, axial) and its magnitude should be assessed to select a coupling with the appropriate flexibility. Elastic sleeve pin couplings are suitable for minor misalignments, while pin gear couplings can accommodate larger angular displacements.

- Operating Speed: The maximum operating speed of the coupling must be compatible with the rotational speed of the shafts. High-speed applications require couplings with balanced components to minimize vibration and prevent centrifugal forces from damaging the pins and hubs.

- Environmental Conditions: The operating environment (temperature, humidity, presence of chemicals, dust, or saltwater) should be considered when selecting materials for the coupling components. For example, high-temperature applications require elastomeric materials with high heat resistance, while marine applications require corrosion-resistant metals.

- Shaft Size and Space Constraints: The coupling must fit within the available physical space and be compatible with the diameter of the driving and driven shafts. Custom couplings may be required for applications with non-standard shaft sizes or space limitations.

- Maintenance Requirements: Applications with limited access for maintenance should use couplings that require minimal upkeep, such as elastic sleeve pin couplings with easily replaceable sleeves.

7.2 Maintenance Best Practices

Regular maintenance is critical to ensuring the long-term performance and reliability of pin couplings. The following maintenance practices are recommended:

- Regular Inspection: Inspect the coupling periodically for signs of wear, damage, or misalignment. Check the pins, elastomeric sleeves, and hubs for cracks, corrosion, or excessive wear. Pay particular attention to the connection points between the hubs and shafts to ensure that set screws or keys are secure.

- Replacement of Worn Components: Replace elastomeric sleeves, non-metallic pins, or worn metallic pins as soon as signs of degradation are detected. Delaying replacement can lead to increased vibration, reduced torque transmission, and eventual failure of the coupling.

- Alignment Checks: Periodically check the alignment of the driving and driven shafts. Misalignment can increase stress on the coupling components, leading to premature wear. Adjust the shafts as needed to maintain proper alignment within the coupling’s allowable limits.

- Lubrication (if required): While most pin couplings do not require lubrication, some heavy-duty or high-speed designs may need periodic lubrication of the pin holes or hub connections. Follow the manufacturer’s recommendations for lubricant type and frequency.

- Cleaning: Keep the coupling clean and free of dust, debris, and oil buildup. Accumulated debris can cause abrasion of the coupling components, while oil can degrade elastomeric materials.

8. Conclusion

Pin couplings are a versatile and cost-effective solution for power transmission in a wide range of industrial, agricultural, and marine applications. Their simple design, ease of installation, and ability to accommodate misalignment and dampen vibrations make them a popular choice for both light-duty and heavy-duty machinery. By understanding the different design variations, material options, advantages, and limitations of pin couplings, engineers and equipment operators can select the appropriate coupling for their specific application requirements.

Proper selection and regular maintenance are key to maximizing the performance and longevity of pin couplings. By following best practices for selection (considering torque, speed, misalignment, and environmental conditions) and maintenance (regular inspection, component replacement, and alignment checks), pin couplings can provide reliable power transmission for many years, minimizing downtime and reducing operational costs.

As industrial machinery continues to evolve, pin couplings are likely to remain a critical component in power transmission systems due to their adaptability and cost-effectiveness. Advances in material technology, such as the development of high-performance elastomers and corrosion-resistant metals, will further enhance the capabilities of pin couplings, making them suitable for even more demanding applications in the future.

« Pin Couplings » Post Date: 2023/7/3

URL: http://www.rokee.com/en/tags/PinCouplings.html