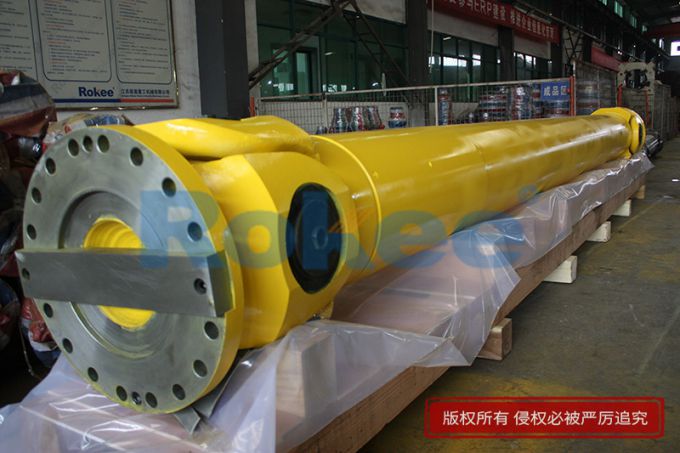

Universal Couplings

Rokee is Universal Couplings Manufacturer, Customizable according to the universal couplings drawings provided by the customer, Support Export.

Our Universal Couplings are widely used and have many impressive records. From micro products for modern logistics, artificial intelligence machinery, light products used in the paper industry, high speed and high performance products for engineering and railway vehicles, to super heavy duty products used in metallurgical rolling system systems, Rokee has won us with mature products and quality Long-term trust of customers, widely exported to Europe, America and other parts of the world.

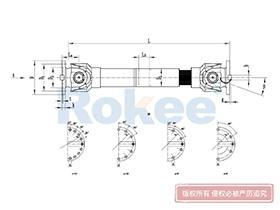

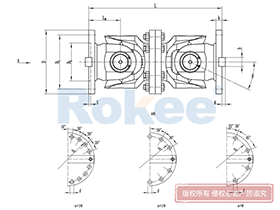

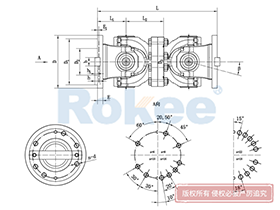

SWC-BH Universal Coupling

standard telescopic welded

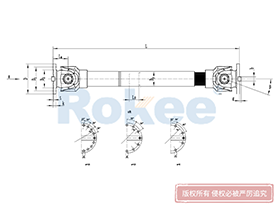

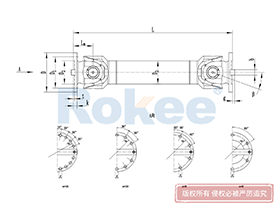

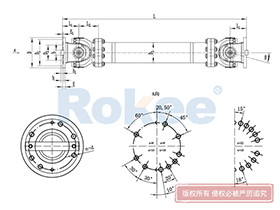

View MoreSWC-CH Uuniversal Coupling

Long Telescopic Welded

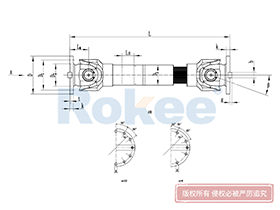

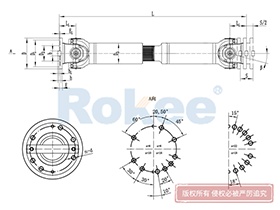

View MoreSWC-DH Universal Coupling

Short Telescopic Welded

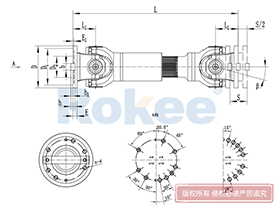

View MoreSWC-WD Universal Coupling

Non-telescopic Short

View MoreSWC-WH Universal Coupling

Non-telescopic Welded

View MoreSWP-A Universal Coupling

Long Type, Telescopic

View MoreSWP-B Universal Coupling

Short Type, Telescopic

View MoreSWP-C Universal Coupling

Short Type, Non-telescopic

View MoreSWP-D Universal Coupling

Long Type, Non-elescopic

View More

In the realm of mechanical power transmission, the ability to transfer rotational motion and torque between misaligned shafts stands as a critical challenge. Among the various components engineered to address this challenge, the universal coupling—also commonly referred to as a universal joint or U-joint—emerges as a versatile and indispensable solution. This mechanical device is specifically designed to connect two rigid shafts whose axes are inclined to each other, enabling efficient power transmission even as the angle between the shafts changes during operation. From automotive drivetrains to industrial machinery and agricultural equipment, universal couplings play a pivotal role in ensuring the smooth and reliable operation of countless mechanical systems.

1. Structural Composition and Working Principles

The fundamental structure of a universal coupling is relatively simple yet ingeniously designed to achieve its core function of transmitting power between misaligned shafts. The basic components of a standard universal coupling include two yokes, a cross-shaped central member (often referred to as a spider), and needle bearings. Each yoke is attached to one of the two shafts that need to be connected. The cross-shaped spider features four arms, each of which is inserted into a bearing mounted within the end of a yoke. This configuration allows the yokes to pivot relative to each other around the spider, accommodating angular misalignment between the shafts.

The working principle of a universal coupling revolves around the ability of the cross spider to transfer rotational motion from the input yoke to the output yoke. When the input shaft rotates, it drives the attached yoke, which in turn rotates the cross spider. The spider then imparts this rotational motion to the output yoke, causing the output shaft to rotate. The needle bearings installed between the spider's arms and the yokes reduce friction, enabling smooth pivoting movement and minimizing wear during operation. This design allows the coupling to accommodate angular misalignment between the input and output shafts—typically within a range of 15 to 45 degrees, depending on the specific type and design of the coupling.

However, it is important to note that a single universal coupling (also known as a single Cardan joint) does not transmit motion at a constant velocity when there is an angle between the shafts. This phenomenon, known as angular velocity fluctuation, occurs because the effective radius of the yoke's connection to the spider changes as the joint rotates. The output shaft's rotational speed alternately increases and decreases during each full rotation of the input shaft, leading to vibrations and potential stress on the connected machinery. To address this issue, engineers utilize double universal couplings (double Cardan joints), which consist of two single joints connected by an intermediate shaft. When properly aligned—with the two joints oriented 90 degrees out of phase and the angles between the input/intermediate shafts and intermediate/output shafts equal—the velocity fluctuations of each joint cancel each other out, resulting in constant-velocity power transmission.

2. Classification of Universal Couplings

Universal couplings are available in a variety of types, each designed to meet specific application requirements related to misalignment tolerance, torque capacity, rotational speed, and environmental conditions. The primary classification criteria include the type of motion transmission (constant velocity vs. non-constant velocity), structural design, and flexibility. The following are the most common types of universal couplings:

2.1 Cross-Axis Universal Couplings (Non-Constant Velocity)

Cross-axis universal couplings, also known as Hooke's joints or single Cardan joints, are the most basic and widely used type of universal coupling. As their name suggests, they feature a cross-shaped spider connecting two yokes, and they are designed to accommodate angular misalignment between shafts. However, as previously noted, they exhibit non-constant velocity transmission when misaligned, making them most suitable for low to moderate speed applications where minor vibrations are acceptable.

Common subtypes of cross-axis universal couplings include:

- Standard Cross-Axis Couplings: Featuring a simple design with two yokes and a cross spider, these couplings are cost-effective and widely used in applications such as agricultural machinery, low-speed industrial equipment, and light-duty automotive components.

- Telescopic Cross-Axis Couplings: Equipped with a telescopic intermediate shaft (often featuring splines), these couplings can accommodate both angular misalignment and axial displacement (linear movement of the shafts along their axes). This makes them ideal for applications where thermal expansion or contraction of the shafts occurs, such as in industrial drivelines and heavy-duty machinery.

2.2 Constant Velocity (CV) Universal Couplings

Constant velocity universal couplings are specifically designed to eliminate angular velocity fluctuations, enabling smooth power transmission at constant speed even when the shafts are misaligned. They are widely used in high-speed applications where precision and minimal vibration are critical, such as automotive drivetrains (particularly front-wheel drive vehicles), precision machinery, and aerospace components. The two most common types of CV joints are:

- Ball Cage CV Joints: Also known as Rzeppa joints, these couplings feature an inner race (connected to the input shaft), an outer race (connected to the output shaft), a cage, and multiple steel balls. The inner and outer races are designed with curved grooves that guide the steel balls, ensuring that the balls always lie in the plane that bisects the angle between the input and output shafts. This configuration guarantees constant velocity transmission, even at large misalignment angles (up to 45 degrees in some designs). Ball cage CV joints are known for their high torque capacity, durability, and sealed design, which allows for maintenance-free operation.

- Ball Fork CV Joints: Featuring a simpler design than ball cage joints, ball fork CV joints consist of two forks (one connected to each shaft) and a set of steel balls that ride in grooves on the forks. While they also provide constant velocity transmission, they have a lower torque capacity and smaller maximum misalignment angle compared to ball cage joints. As a result, they are typically used in light-duty applications such as small vehicles and precision instruments.

2.3 Flexible Universal Couplings

Flexible universal couplings incorporate elastic elements (such as rubber, polyurethane, or metal springs) into their design, enabling them to absorb shocks, dampen vibrations, and accommodate minor misalignments. Unlike rigid universal couplings, they do not rely solely on mechanical pivots for flexibility; instead, the elastic elements provide both flexibility and torque transmission. These couplings are ideal for applications where vibration reduction is critical, such as pumps, compressors, conveyor systems, and food processing machinery (where stainless steel versions are often used to meet hygiene requirements).

2.4 Specialized Universal Couplings

In addition to the standard types, there are several specialized universal couplings designed for specific industrial applications:

- Flange-Mounted Universal Couplings: Featuring flange connections for easy installation and removal, these couplings are commonly used in modular equipment and industrial machinery where quick maintenance is required.

- Drum Gear Universal Couplings: With external teeth machined into a spherical surface, these couplings offer a higher angular misalignment tolerance (up to 50% more than straight-tooth couplings) and increased load-bearing capacity (15-20% higher). They are widely used in heavy-duty applications such as metallurgical equipment, mining machinery, and rolling mills.

- Composite Material Universal Couplings: Utilizing advanced materials such as carbon fiber-reinforced polymers, these couplings are extremely lightweight and offer excellent fatigue resistance. They are primarily used in high-performance applications such as aerospace, racing vehicles, and robotics, where weight reduction is critical.

3. Material Selection for Universal Couplings

The performance, durability, and suitability of a universal coupling for a specific application are heavily influenced by the choice of materials. Factors such as torque requirements, operating temperature, environmental conditions (e.g., moisture, corrosion, dust), and weight constraints must be carefully considered when selecting materials. The most commonly used materials for universal couplings include:

3.1 Alloy Steels

Alloy steels—such as 40Cr, 42CrMo, and 20CrMnTi—are the most widely used materials for heavy-duty universal couplings. These steels offer excellent strength, toughness, and wear resistance when subjected to heat treatment processes such as quenching and tempering. For example, 42CrMo alloy steel, when heat-treated, achieves a hardness of HRC 28-32, making it ideal for use in cross shafts and yokes of couplings used in mining machinery, rolling mills, and other high-torque applications. 20CrMnTi steel is often used for cross shafts due to its excellent carburizing properties, which enhance surface hardness (up to HRC 58-62) while maintaining core toughness.

3.2 Carbon Steels

Carbon steels—such as 45-grade steel—are a cost-effective alternative to alloy steels for light to moderate duty applications. These steels can be heat-treated to improve surface hardness, making them suitable for use in agricultural machinery, small industrial equipment, and other applications with lower torque requirements. However, carbon steels have poor corrosion resistance and require regular lubrication and anti-rust treatments to extend their service life.

3.3 Stainless Steels

Stainless steels—primarily 304 and 316 grades—are used in universal couplings that operate in corrosive environments, such as marine applications, food processing plants, chemical facilities, and medical equipment. 304 stainless steel offers excellent corrosion resistance and surface光洁度, making it suitable for applications where hygiene and resistance to moisture are critical. 316 stainless steel, which contains molybdenum, provides enhanced resistance to chloride corrosion, making it ideal for marine environments and seawater applications (e.g., offshore platforms, desalination plants).

3.4 Aluminum Alloys

Aluminum alloys are used in applications where weight reduction is a priority, such as aerospace components, robotics, and high-speed machinery. These alloys have a density of approximately one-third that of steel, making them lightweight while still offering sufficient strength for low to moderate torque requirements. Aluminum alloy couplings are commonly used in drones, automated production lines, and precision instruments where high rotational speeds and minimal inertia are critical.

3.5 Composite Materials

Composite materials—such as carbon fiber-reinforced polymers (CFRP) and nylon-coated metals—are increasingly used in high-performance and specialized applications. CFRP couplings offer exceptional strength-to-weight ratios, excellent fatigue resistance, and low thermal expansion, making them ideal for aerospace and racing applications. Nylon-coated metal couplings combine the strength of a metal core with the vibration-damping and corrosion-resistant properties of nylon, making them suitable for precision instruments and food processing equipment.

4. Advantages and Limitations of Universal Couplings

Universal couplings offer a range of advantages that make them indispensable in many mechanical systems, but they also have certain limitations that must be considered during the design and selection process.

4.1 Advantages

- Excellent Misalignment Compensation: One of the primary advantages of universal couplings is their ability to accommodate angular misalignment between shafts. This flexibility makes them ideal for applications where shafts cannot be perfectly aligned, such as in automotive drivetrains, construction machinery, and industrial equipment where dynamic movement occurs during operation.

- High Torque Transmission Capacity: When constructed from high-strength materials such as alloy steels, universal couplings can transmit large amounts of torque, making them suitable for heavy-duty applications such as mining machinery, rolling mills, and marine propulsion systems. Their can exceed 98%, ensuring minimal energy loss during power transmission.

- Compact and Versatile Design: Universal couplings have a compact structure, making them suitable for use in applications with limited installation space. They are also available in a wide range of types and sizes, enabling them to be tailored to specific application requirements—from light-duty precision instruments to heavy-duty industrial machinery.

- Cost-Effective Solution: Standard universal couplings (such as cross-axis types) are relatively inexpensive to manufacture, making them a cost-effective choice for many applications. Even specialized types, such as ball cage CV joints, offer good value for money when compared to alternative misalignment-compensating components.

- Shock and Vibration Absorption (Flexible Types): Flexible universal couplings, which incorporate elastic elements, can absorb shocks and dampen vibrations, reducing wear and tear on connected machinery and improving overall system reliability. This makes them ideal for applications such as pumps, compressors, and conveyor systems where vibration is a concern.

4.2 Limitations

- Velocity Fluctuations (Single Joints): As previously noted, single universal couplings exhibit non-constant velocity transmission when misaligned, leading to vibrations and potential stress on connected components. This limits their use in high-speed applications where smooth operation is critical, unless a double Cardan joint or CV joint is used.

- Maintenance Requirements: Rigid universal couplings (such as cross-axis types) require regular lubrication of the needle bearings to reduce friction and prevent wear. In harsh environments (e.g., dust, moisture, high temperatures), the seals can degrade, leading to contamination of the bearings and premature failure. Regular inspection and maintenance are therefore essential to ensure optimal performance.

- Limited Misalignment Range: While universal couplings can accommodate angular misalignment, they have a maximum allowable angle (typically 15-45 degrees, depending on the type). Exceeding this angle can lead to increased wear, reduced efficiency, and eventual failure of the coupling.

- High-Speed Balancing Requirements: At high rotational speeds, even minor imbalances in the coupling can cause significant vibrations. This requires careful balancing during manufacturing, which can increase production costs for high-speed applications.

- Cost of Specialized Types: High-performance universal couplings, such as CV joints and composite material couplings, are more expensive to manufacture than standard types. This can be a limiting factor for applications with tight budget constraints.

5. Applications of Universal Couplings

The versatility and flexibility of universal couplings make them suitable for a wide range of applications across numerous industries. From automotive and aerospace to industrial manufacturing and agriculture, these components play a critical role in ensuring efficient power transmission. The following are some of the most common application areas:

5.1 Automotive Industry

The automotive industry is one of the largest users of universal couplings. In rear-wheel drive vehicles, single or double universal couplings are used in the drive shaft to transmit power from the transmission to the rear differential. In front-wheel drive vehicles, CV joints are used in the half-shafts to transmit power from the transaxle to the front wheels, enabling smooth power transmission even as the wheels turn and the suspension moves. Universal couplings are also used in steering systems, where they allow for the transfer of rotational motion from the steering wheel to the steering rack at an angle.

5.2 Industrial Manufacturing

In industrial manufacturing, universal couplings are used in a wide range of machinery, including rolling mills, conveyors, pumps, compressors, and machine tools. For example, in rolling mills, heavy-duty drum gear universal couplings are used to transmit high torque between the motor and the rolling stands, accommodating the misalignment caused by thermal expansion and the dynamic loads of the rolling process. In conveyor systems, flexible universal couplings are used to connect the motor to the conveyor drive, absorbing shocks and vibrations and accommodating minor misalignments.

5.3 Agricultural Machinery

Agricultural machinery—such as tractors, harvesters, and tillers—relies heavily on universal couplings to transmit power between various components. These machines often operate in harsh and uneven terrain, leading to significant misalignment between shafts. Standard cross-axis universal couplings are commonly used in tractor PTO (Power Take-Off) shafts, enabling the transfer of power from the tractor's engine to implements such as mowers, plows, and harvesters. Telescopic universal couplings are also used in agricultural machinery to accommodate the axial movement of shafts during operation.

5.4 Aerospace and Defense

In the aerospace and defense industries, universal couplings are used in aircraft engines, helicopter rotors, and missile systems. These applications require high-performance couplings that can withstand extreme temperatures, high rotational speeds, and high torque loads. Composite material and precision-engineered CV joints are commonly used in these applications, as they offer lightweight construction, high strength, and reliable constant-velocity power transmission. For example, in helicopter rotors, universal couplings enable the transfer of power from the engine to the rotor blades while accommodating the dynamic movement of the rotor system.

5.5 Marine Industry

The marine industry uses universal couplings in ship propulsion systems, where they transmit power from the engine to the propeller shaft. These couplings must be able to withstand corrosive marine environments, high torque loads, and misalignment caused by the ship's movement. Stainless steel and corrosion-resistant alloy couplings are commonly used in marine applications, ensuring durability and reliability in saltwater environments. In addition, telescopic universal couplings are used to accommodate the axial movement of the propeller shaft caused by thermal expansion and the ship's hull flexing.

5.6 Medical and Precision Equipment

In medical and precision equipment—such as MRI machines, surgical robots, and laboratory instruments—universal couplings are used to transmit rotational motion with high precision and minimal vibration. Stainless steel and aluminum alloy couplings are commonly used in these applications, as they offer corrosion resistance, lightweight construction, and smooth operation. Flexible universal couplings are also used to dampen vibrations, ensuring the accuracy of delicate medical procedures and laboratory measurements.

6. Conclusion

Universal couplings stand as a cornerstone of mechanical power transmission, enabling the efficient and reliable transfer of rotational motion and torque between misaligned shafts. From their ancient origins to their modern-day applications in automotive, industrial, and aerospace systems, these components have evolved significantly, with diverse types and materials tailored to meet specific application requirements. Whether it is a simple cross-axis coupling for agricultural machinery, a precision CV joint for a front-wheel drive vehicle, or a high-performance composite coupling for aerospace applications, universal couplings play a critical role in ensuring the smooth operation of countless mechanical systems.

Understanding the structural composition, working principles, classification, material selection, and advantages and limitations of universal couplings is essential for engineers and designers tasked with selecting the appropriate coupling for a given application. By carefully considering factors such as torque requirements, misalignment tolerance, operating speed, and environmental conditions, one can select a universal coupling that optimizes performance, reliability, and cost-effectiveness.

As technology continues to advance, the development of universal couplings is likely to focus on improving efficiency, reducing maintenance requirements, and expanding their use in emerging applications such as electric vehicles, renewable energy systems, and advanced robotics. With their inherent versatility and adaptability, universal couplings will undoubtedly remain a vital component in the world of mechanical engineering for years to come.

« Universal Couplings » Post Date: 2024/1/16

URL: http://www.rokee.com/en/tags/universal-couplings.html