Universal Shaft Couplings

Rokee is Universal Shaft Couplings Manufacturer, Customizable according to the universal shaft couplings drawings provided by the customer, Support Export.

Our Universal Shaft Couplings are widely used and have many impressive records. From micro products for modern logistics, artificial intelligence machinery, light products used in the paper industry, high speed and high performance products for engineering and railway vehicles, to super heavy duty products used in metallurgical rolling system systems, Rokee has won us with mature products and quality Long-term trust of customers, widely exported to Europe, America and other parts of the world.

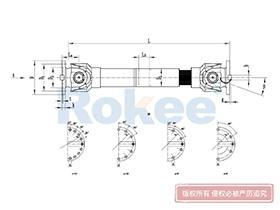

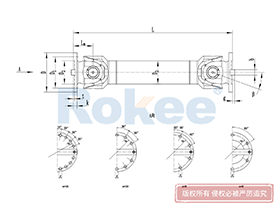

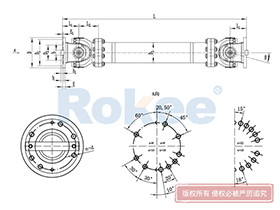

SWC-BH Universal Coupling

standard telescopic welded

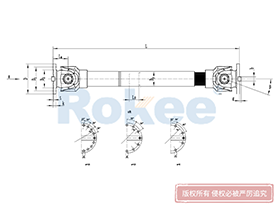

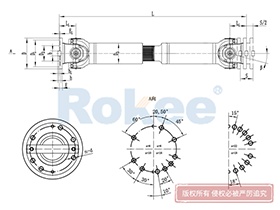

View MoreSWC-CH Uuniversal Coupling

Long Telescopic Welded

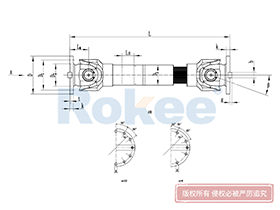

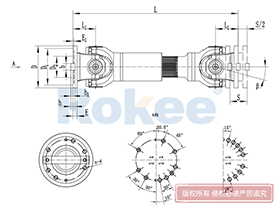

View MoreSWC-DH Universal Coupling

Short Telescopic Welded

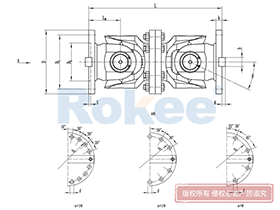

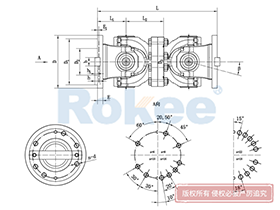

View MoreSWC-WD Universal Coupling

Non-telescopic Short

View MoreSWC-WH Universal Coupling

Non-telescopic Welded

View MoreSWP-A Universal Coupling

Long Type, Telescopic

View MoreSWP-B Universal Coupling

Short Type, Telescopic

View MoreSWP-C Universal Coupling

Short Type, Non-telescopic

View MoreSWP-D Universal Coupling

Long Type, Non-elescopic

View More

In the complex landscape of mechanical power transmission, the universal shaft coupling stands as a pivotal component that bridges the gap between misaligned shafts, enabling efficient and reliable torque transfer across a wide range of industrial and automotive applications. Unlike rigid couplings that demand precise alignment, universal shaft couplings are engineered to accommodate angular, radial, and axial misalignments, making them indispensable in scenarios where perfect coaxiality between driving and driven shafts is impractical or impossible. From heavy-duty steel mills and mining equipment to automotive drive shafts and precision robotics, these couplings play a critical role in ensuring the smooth operation of machinery, minimizing energy loss, and extending the service life of connected components.

1. Fundamental Principles of Universal Shaft Couplings

At its core, a universal shaft coupling is a mechanical device designed to transmit rotational motion and torque between two shafts that are not in perfect alignment. The primary distinction between universal couplings and other types of couplings (such as rigid or flexible couplings with elastic elements) lies in their ability to handle significant angular misalignments—typically ranging from 5° to 45° depending on the design—while maintaining relatively high transmission efficiency. The basic working principle revolves around the use of articulated joints that allow the coupling to pivot as the shafts rotate, compensating for misalignments without disrupting torque transfer.

The key mechanical component enabling this articulation is the universal joint, which consists of two yokes (one attached to each shaft) and a cross-shaped intermediate member (known as a cross or spider) that connects the yokes. Needle bearings or bushings are often installed at the junctions between the cross and the yokes to reduce friction and ensure smooth rotation. When the driving shaft rotates, it imparts rotational force to the cross via one yoke, which then transmits this force to the second yoke and ultimately to the driven shaft. This design allows the two shafts to operate at an angle to each other, as the cross can pivot freely within the yokes.

A critical consideration in the operation of universal shaft couplings is the issue of angular velocity variation. A single universal joint (also known as a Hooke's joint) introduces a periodic fluctuation in the angular velocity of the driven shaft when the shafts are misaligned. This fluctuation occurs because the effective radius of the cross relative to the yokes changes as the joint rotates, leading to non-uniform torque transfer. To mitigate this issue, most applications employ a double universal joint configuration, which consists of two universal joints connected by an intermediate shaft. When properly aligned, the angular velocity variations from the first joint are canceled out by the second joint, resulting in constant velocity transmission between the driving and driven shafts.

Another important principle of universal shaft couplings is their ability to accommodate axial displacement. Many designs incorporate splined connections between the coupling and the shafts, allowing the coupling to slide along the shaft axis. This feature is particularly useful in applications where thermal expansion or contraction of shafts occurs, such as in high-temperature industrial processes, as it prevents the buildup of axial stresses that could damage the coupling or connected machinery.

2. Common Types of Universal Shaft Couplings

Universal shaft couplings are available in a variety of designs, each tailored to specific application requirements such as torque capacity, speed, misalignment range, and environmental conditions. The most common types include cross-shaft universal couplings, ball cage universal couplings, ball hinge universal couplings, and three-pin universal couplings. Each type exhibits unique structural features and performance characteristics, making them suitable for distinct operational scenarios.

2.1 Cross-Shaft Universal Couplings

Cross-shaft universal couplings, also known as Hooke's joint couplings, are the most widely used type of universal shaft coupling. Their structure consists of two yokes, a cross-shaped spider, and bearings (typically needle bearings) at the four ends of the cross. This design offers high torque-carrying capacity and excellent angular misalignment compensation, making it ideal for heavy-duty, low-to-medium speed applications.

Cross-shaft couplings are further categorized based on their yoke design and bearing configuration. The most common sub-types include:

- Integral Yoke Type: Characterized by a one-piece yoke design, this type is highly rigid and suitable for heavy-load applications such as metallurgical rolling mills and mining equipment. The integral construction minimizes stress concentration, allowing it to withstand high torque and shock loads.

- Split Bearing Block Type: This design features a split bearing housing that allows for easy maintenance and replacement of bearings without disassembling the entire coupling. It is commonly used in rolling machinery and other applications where regular maintenance access is required.

- Small Light-Duty Type: Designed for low-torque, light-load applications, this sub-type has a compact structure and is suitable for angular misalignments up to 45°. It is often used in light industrial equipment, agricultural machinery, and small-scale conveyors.

One of the main advantages of cross-shaft universal couplings is their robust construction and high reliability in harsh environments. However, they are prone to vibration and noise at high speeds due to the periodic contact between the cross and yokes, and they require regular lubrication to maintain bearing performance and prevent wear.

2.2 Ball Cage Universal Couplings

Ball cage universal couplings, also known as constant velocity (CV) couplings, are designed for high-speed, precision applications where constant velocity transmission is critical. Unlike cross-shaft couplings, ball cage couplings use a spherical cage containing steel balls to transmit torque between the driving and driven shafts. The cage and balls are housed within a spherical outer race and a spherical inner race, which are machined with matching ball grooves.

The key advantage of ball cage universal couplings is their ability to provide constant velocity transmission even at large angular misalignments. The steel balls in the cage ensure that the torque is transmitted through a constant contact point between the inner and outer races, eliminating the angular velocity fluctuations associated with single cross-shaft couplings. This feature makes them ideal for high-speed applications such as automotive drive shafts, precision machine tools, and industrial robots.

Ball cage couplings also exhibit low vibration and noise levels, high transmission efficiency (typically above 98%), and good resistance to wear. However, their complex manufacturing process results in higher costs compared to cross-shaft couplings, and their torque capacity is generally lower, making them less suitable for heavy-duty applications.

2.3 Ball Hinge Universal Couplings

Ball hinge universal couplings utilize a spherical hinge structure instead of a cross shaft to connect the yokes. This design offers higher radial load capacity than cross-shaft couplings and is capable of accommodating moderate angular misalignments (typically up to 10° for single ball hinge designs and higher for double ball hinge designs).

The spherical hinge consists of a ball-shaped element attached to one yoke and a socket attached to the other yoke, with a lubricated interface to reduce friction. This structure provides good rigidity and stability, making ball hinge couplings suitable for applications where radial loads are present, such as in petroleum machinery and marine propulsion systems. Double ball hinge designs offer increased misalignment compensation but slightly lower torque transmission capacity compared to single ball hinge designs.

2.4 Three-Pin Universal Couplings

Three-pin universal couplings feature a compact design consisting of three pins attached to one yoke and three corresponding slots in the other yoke. The pins engage with the slots to transmit torque, allowing for angular misalignment and axial displacement. This type of coupling is characterized by its small size, light weight, and large swing angle, making it suitable for medium-load, low-speed applications where space is limited.

Three-pin couplings are often used in agricultural machinery, small conveyors, and light industrial equipment. Their simple structure allows for easy manufacturing and maintenance, but their torque capacity is lower than that of cross-shaft and ball hinge couplings, limiting their use in heavy-duty applications.

3. Key Characteristics and Performance Metrics

When selecting a universal shaft coupling for a specific application, it is essential to consider its key performance characteristics, which include torque capacity, transmission efficiency, misalignment compensation range, speed limit, and durability. These metrics determine the coupling's suitability for the intended operation and its ability to perform reliably over time.

3.1 Torque Capacity

Torque capacity refers to the maximum torque that a coupling can transmit without suffering permanent deformation or failure. It is the most critical performance metric for universal shaft couplings, as it directly determines the coupling's compatibility with the power output of the driving shaft. The torque capacity of a coupling depends on factors such as its material, structural design, and bearing type.

In practical applications, the design torque (the maximum torque the coupling will experience during operation) should be calculated by multiplying the nominal torque (calculated based on the power and speed of the driving shaft) by a service factor. The service factor accounts for factors such as shock loads, vibration, and duty cycle, and varies depending on the type of driving machine and the operating conditions. For example, applications with internal combustion engines (which produce higher shock loads) require a higher service factor than those with electric motors.

3.2 Transmission Efficiency

Transmission efficiency is the ratio of the torque transmitted to the driven shaft to the torque input from the driving shaft, expressed as a percentage. High transmission efficiency is desirable as it minimizes energy loss and reduces operating costs. Universal shaft couplings typically exhibit high transmission efficiency, with cross-shaft designs ranging from 98% to 99% and ball cage designs exceeding 99% in most cases.

The main factors affecting transmission efficiency are friction between the coupling components (such as between the cross and bearings in cross-shaft couplings) and the angle of misalignment. Higher misalignment angles can lead to increased friction and slightly lower efficiency, although this effect is minimal in properly lubricated couplings. Regular lubrication is therefore essential to maintain high transmission efficiency and prevent excessive wear.

3.3 Misalignment Compensation Range

The misalignment compensation range is the maximum amount of angular, radial, and axial misalignment that a coupling can accommodate while maintaining normal operation. Angular misalignment is the angle between the axes of the driving and driven shafts, radial misalignment is the parallel offset between the shafts, and axial misalignment is the relative displacement along the shaft axes.

Cross-shaft universal couplings excel in angular misalignment compensation, with some designs capable of handling angles up to 45°. Ball cage couplings can also accommodate large angular misalignments while maintaining constant velocity transmission. Radial misalignment compensation is typically lower than angular misalignment compensation for most universal shaft couplings, while axial displacement is often accommodated through splined connections or sliding yokes.

3.4 Speed Limit

The speed limit is the maximum rotational speed at which a coupling can operate without experiencing excessive vibration, noise, or failure. This metric is determined by the coupling's mass distribution, balance quality, and bearing design. High-speed applications require couplings with good dynamic balance to minimize centrifugal forces, which can cause vibration and damage to the coupling and connected machinery.

Ball cage couplings are well-suited for high-speed applications, with speed limits often exceeding 10,000 rpm, while cross-shaft couplings are typically limited to lower speeds (up to 3,000 rpm for heavy-duty designs). The speed limit of a coupling should always be higher than the maximum operating speed of the application to ensure safe and reliable operation.

3.5 Durability and Environmental Resistance

Durability refers to the ability of a coupling to withstand the rigors of long-term operation, including wear, fatigue, and exposure to harsh environmental conditions. The durability of a universal shaft coupling depends on the quality of materials used (such as alloy steel, carbon steel, or stainless steel), the manufacturing precision, and the effectiveness of lubrication and sealing systems.

Environmental factors such as temperature, humidity, dust, and corrosive substances can significantly impact the performance and service life of a coupling. For example, high-temperature applications require couplings made from heat-resistant materials, while corrosive environments may require stainless steel or coated components. Sealed designs are also available to prevent the ingress of dust, dirt, and moisture, which can cause premature wear of bearings and other moving parts.

3. Selection Criteria for Universal Shaft Couplings

Selecting the right universal shaft coupling for a specific application requires a systematic evaluation of several key factors, including torque requirements, speed, misalignment type and magnitude, shaft dimensions, installation space, environmental conditions, and maintenance accessibility. The following steps provide a structured approach to coupling selection:

3.1 Define Core Requirements

The first step in selecting a universal shaft coupling is to define the core requirements of the application, including the nominal torque, peak torque (shock load), operating speed, and the type and magnitude of misalignment. The nominal torque can be calculated using the formula: Tn (N·m) = 9550 × P (kW) / n (rpm), where P is the power of the driving machine and n is the rotational speed. The peak torque should be calculated by multiplying the nominal torque by the appropriate service factor, as discussed earlier.

It is also important to determine the type of misalignment (angular, radial, axial, or a combination) and the maximum misalignment magnitude. This information can be obtained from the equipment design specifications or through on-site measurements.

3.2 Evaluate Shaft Dimensions and Installation Space

The next step is to evaluate the dimensions of the driving and driven shafts, including the shaft diameter, keyway size, and the distance between the shaft ends (DBSE). The coupling must be compatible with the shaft diameter and keyway dimensions to ensure a secure fit. The DBSE determines the length of the coupling and, in some cases, the need for an intermediate shaft.

Installation space constraints are also a critical consideration. Compact designs such as three-pin couplings or ball hinge couplings are suitable for applications with limited space, while larger cross-shaft couplings may be required for heavy-duty applications where space is not a constraint.

3.3 Consider Environmental Conditions

Environmental conditions such as temperature, humidity, dust, dirt, and corrosive substances can have a significant impact on the performance and service life of the coupling. For high-temperature applications (e.g., in steel mills or glass manufacturing), couplings made from heat-resistant alloys should be selected. In corrosive environments (e.g., in chemical processing plants or marine applications), stainless steel or corrosion-resistant coatings are recommended. Sealed bearings and protective covers can also be used to prevent the ingress of contaminants.

3.4 Assess Maintenance Requirements

Maintenance requirements vary depending on the type of coupling. Cross-shaft couplings require regular lubrication of bearings to prevent wear, while ball cage couplings are often maintenance-free due to their sealed design. In applications where maintenance access is limited, such as in underground mining equipment, maintenance-free or easy-to-maintain couplings should be prioritized.

3.5 Verify Performance Compatibility

Finally, it is essential to verify that the selected coupling's performance metrics (torque capacity, speed limit, misalignment compensation range) are compatible with the application requirements. The coupling's torque capacity should be greater than the calculated peak torque, and its speed limit should be higher than the maximum operating speed. The misalignment compensation range should also be sufficient to accommodate the maximum expected misalignment in the application.

4. Applications of Universal Shaft Couplings

Universal shaft couplings are used in a wide range of industries and applications, thanks to their ability to accommodate misalignments and transmit torque efficiently. The following sections highlight the key application areas of universal shaft couplings, along with the specific types of couplings commonly used in each area.

4.1 Automotive Industry

The automotive industry is one of the largest users of universal shaft couplings, primarily in drive shaft assemblies. In rear-wheel drive and four-wheel drive vehicles, universal couplings are used to connect the transmission to the drive axle, accommodating the angular misalignment between the transmission output shaft and the axle input shaft as the vehicle travels over uneven terrain.

Ball cage universal couplings (CV joints) are commonly used in front-wheel drive vehicles, as they provide constant velocity transmission to the front wheels, which both drive and steer the vehicle. The constant velocity feature ensures smooth power delivery and minimizes vibration, even at high speeds and large steering angles. Cross-shaft couplings are also used in heavy-duty vehicles such as trucks and buses, where high torque capacity is required.

4.2 Industrial Machinery

Universal shaft couplings are widely used in various industrial machinery applications, including metallurgical equipment, mining machinery, paper mills, and cement plants. In metallurgical rolling mills, cross-shaft universal couplings are used to transmit torque between the motor and the rolling rolls, accommodating the angular misalignment caused by roll adjustment and thermal expansion. The high torque capacity and robust construction of cross-shaft couplings make them ideal for this demanding application.

In mining equipment such as excavators and conveyor systems, universal shaft couplings are used to connect hydraulic motors to rotating components, such as the excavator's mechanism or the conveyor's drive roller. These applications require couplings that can withstand high shock loads and harsh environmental conditions, making cross-shaft and ball hinge couplings the preferred choices.

Paper mills and cement plants also rely on universal shaft couplings for power transmission in machinery such as paper machines and rotary kilns. Ball cage couplings are often used in high-speed paper machines to ensure smooth operation, while cross-shaft couplings are used in rotary kilns to handle the high torque and misalignment associated with these large-scale rotating components.

4.3 Aerospace and Defense

In the aerospace and defense industries, universal shaft couplings are used in aircraft and spacecraft propulsion systems, as well as in military vehicles and equipment. For example, in helicopters, universal couplings are used to transmit torque from the engine to the rotor system, accommodating the angular misalignment between the engine output shaft and the rotor shaft. These applications require couplings that are lightweight, high-strength, and capable of operating in extreme temperature and pressure conditions.

Ball cage and precision cross-shaft couplings are commonly used in aerospace applications, as they offer high reliability and precise torque transmission. The materials used in these couplings are often high-performance alloys, such as titanium or Inconel, to ensure strength and durability in harsh environments.

4.4 Robotics and Automation

The robotics and automation industry requires precise and reliable power transmission components to ensure the accuracy and repeatability of robotic movements. Universal shaft couplings, particularly ball cage and beam couplings (a type of small, flexible universal coupling), are used in robotic arms and other automated equipment to connect motors to joints, accommodating the small angular misalignments that occur during movement.

Beam couplings are a popular choice in robotics due to their compact size, low weight, and ability to provide precise torque transmission with minimal backlash. They are also maintenance-free, making them ideal for automated systems where downtime must be minimized.

4.5 Agricultural Machinery

Agricultural machinery such as tractors, harvesters, and irrigation systems also use universal shaft couplings for power transmission. In tractors, universal couplings are used to connect the tractor's power take-off (PTO) shaft to implements such as plows, harvesters, and mowers, accommodating the angular misalignment between the PTO shaft and the implement's input shaft.

Light-duty cross-shaft and three-pin couplings are commonly used in agricultural applications, as they are cost-effective, easy to maintain, and capable of handling the moderate torque and misalignment requirements of most agricultural machinery.

5. Maintenance and Troubleshooting of Universal Shaft Couplings

Proper maintenance of universal shaft couplings is essential to ensure their reliable operation, extend their service life, and prevent unexpected equipment failure. The maintenance requirements vary depending on the type of coupling, but the key practices include regular lubrication, inspection, and replacement of worn components. This section outlines the basic maintenance procedures and common troubleshooting techniques for universal shaft couplings.

5.1 Lubrication

Lubrication is the most critical maintenance task for universal shaft couplings, particularly for cross-shaft designs with bearings. The purpose of lubrication is to reduce friction between moving components, prevent wear and corrosion, and dissipate heat. The type of lubricant used depends on the coupling's operating conditions, such as temperature, speed, and environmental conditions.

For most industrial applications, grease lubrication is recommended, as grease provides better sealing and stays in place longer than oil. The lubrication interval depends on the operating speed and load, but it is typically recommended to lubricate cross-shaft couplings every 500 to 1,000 operating hours. Ball cage couplings may require less frequent lubrication or may be pre-lubricated and sealed for life, eliminating the need for regular lubrication.

When lubricating a cross-shaft coupling, it is important to ensure that the lubricant reaches all four bearings of the cross. This can be done by removing the grease fittings, applying fresh lubricant until it exits the bearing, and then replacing the grease fittings. Excess lubricant should be wiped away to prevent the accumulation of dirt and debris.

5.2 Inspection

Regular inspection of universal shaft couplings is essential to detect early signs of wear or damage. The inspection should include a visual check of the yokes, cross, bearings, and splined connections for signs of cracks, wear, or corrosion. The coupling should also be checked for excessive vibration, noise, or axial play, which can indicate worn bearings or misalignment.

Key inspection points include:

- Yokes: Check for cracks, deformation, or excessive wear at the bearing seats.

- Cross: Inspect for signs of wear, corrosion, or bending. The ends of the cross should be smooth and free of damage.

- Bearings: Check for excessive play, noise, or leakage of lubricant. Worn bearings should be replaced immediately to prevent further damage to the coupling.

- Splined Connections: Inspect for wear or corrosion on the splines. Excessive wear can lead to axial play and reduced torque transmission capacity.

Inspection intervals should be based on the operating conditions, with more frequent inspections in harsh environments or high-load applications.

5.3 Component Replacement

When worn or damaged components are detected during inspection, they should be replaced promptly to prevent the failure of the entire coupling. Common replacement components include bearings, cross shafts, yokes, and splined sleeves. It is important to use replacement components that are compatible with the coupling's design and specifications to ensure proper fit and performance.

When replacing bearings in a cross-shaft coupling, the old bearings should be removed carefully using appropriate tools to avoid damaging the yokes or cross. The new bearings should be pressed into place and lubricated before reassembling the coupling. Splined components should be cleaned and lubricated before installation to ensure smooth sliding and prevent wear.

5.4 Troubleshooting Common Issues

Common issues with universal shaft couplings include vibration, noise, excessive wear, and torque loss. The following are some common troubleshooting techniques for these issues:

- Vibration: Excessive vibration is often caused by misalignment, worn bearings, or an unbalanced coupling. Checking and correcting the alignment of the shafts, replacing worn bearings, or balancing the coupling can resolve this issue.

- Noise: Noise (such as clicking or grinding) is typically caused by worn bearings or a damaged cross. Replacing the worn or damaged components and ensuring proper lubrication can eliminate the noise.

- Excessive Wear: Excessive wear is often due to insufficient lubrication, misalignment, or overloading. Increasing the lubrication frequency, correcting the alignment, or selecting a coupling with a higher torque capacity can reduce wear.

- Torque Loss: Torque loss can be caused by slipping splined connections or worn bearings. Tightening the splined connections, replacing worn bearings, or using a coupling with a more secure connection can resolve this issue.

6. Conclusion

Universal shaft couplings are essential components in mechanical power transmission systems, enabling efficient and reliable torque transfer between misaligned shafts. Their ability to accommodate angular, radial, and axial misalignments makes them indispensable in a wide range of applications, from automotive drive shafts to heavy-duty industrial machinery. Understanding the fundamental principles, common types, and key performance characteristics of universal shaft couplings is critical for selecting the right coupling for a specific application.

When selecting a universal shaft coupling, it is important to consider factors such as torque capacity, speed, misalignment range, shaft dimensions, environmental conditions, and maintenance requirements. Proper maintenance, including regular lubrication and inspection, is essential to ensure the coupling's reliable operation and extend its service life.

As industrial technology continues to advance, the design and performance of universal shaft couplings are also evolving. New materials and manufacturing processes are being developed to improve torque capacity, reduce weight, and enhance durability, making universal shaft couplings even more versatile and efficient. Whether in automotive, industrial, aerospace, or robotics applications, universal shaft couplings will continue to play a critical role in ensuring the smooth and reliable operation of machinery for years to come.

« Universal Shaft Couplings » Post Date: 2024/1/16

URL: http://www.rokee.com/en/tags/universal-shaft-couplings.html