Cardan Couplings

Rokee is Cardan Couplings Manufacturer, Customizable according to the cardan couplings drawings provided by the customer, Support Export.

Rokee's Cardan Couplings are widely used and have many impressive records. From micro products for modern logistics, artificial intelligence machinery, light products used in the paper industry, high speed and high performance products for engineering and railway vehicles, to super heavy duty products used in metallurgical rolling system systems, Rokee has won us with mature products and quality Long-term trust of customers, widely exported to Europe, America and other parts of the world.

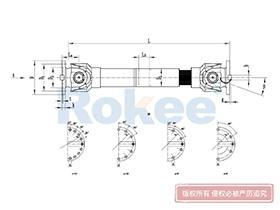

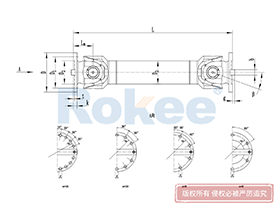

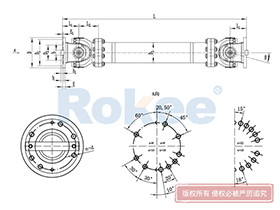

SWC-BH Universal Coupling

standard telescopic welded

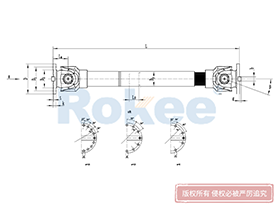

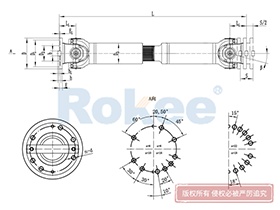

View MoreSWC-CH Uuniversal Coupling

Long Telescopic Welded

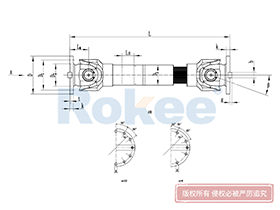

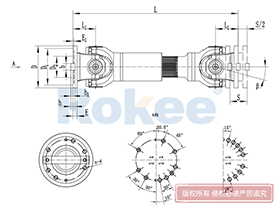

View MoreSWC-DH Universal Coupling

Short Telescopic Welded

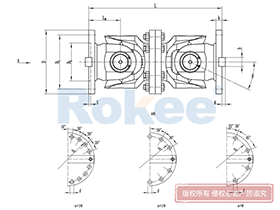

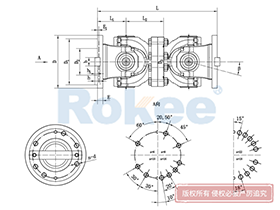

View MoreSWC-WD Universal Coupling

Non-telescopic Short

View MoreSWC-WH Universal Coupling

Non-telescopic Welded

View MoreSWP-A Universal Coupling

Long Type, Telescopic

View MoreSWP-B Universal Coupling

Short Type, Telescopic

View MoreSWP-C Universal Coupling

Short Type, Non-telescopic

View MoreSWP-D Universal Coupling

Long Type, Non-elescopic

View More

In the realm of mechanical power transmission, the ability to transfer torque and rotational motion between non-aligned shafts stands as a fundamental challenge. Among the various solutions developed to address this challenge, the Cardan coupling—also commonly referred to as the universal joint or Hooke's joint—has emerged as a versatile and indispensable component. With a history dating back centuries and continuous evolution to meet modern industrial demands, the Cardan coupling plays a critical role in countless mechanical systems, from automotive drivetrains to heavy industrial machinery and aerospace applications.

Historical Origins and Evolution

The origins of the Cardan coupling can be traced back to the ingenuity of early scholars and inventors, with its development spanning several centuries. The device derives its name from Gerolamo Cardano, a 16th-century Italian polymath, mathematician, and physicist, who made significant contributions to the understanding of gimbals and rotational mechanisms. While Cardano’s writings primarily focused on gimbal mountings, his work laid the groundwork for the subsequent development of the universal joint as we know it today. It is important to note, however, that the concept of transmitting motion between non-aligned shafts was not entirely new; ancient Greek engineers had used primitive forms of such mechanisms in ballistae and other war machinery.

The next major milestone in the evolution of the Cardan coupling came in the 17th century, when the English scientist Robert Hooke conducted a detailed analysis of the joint. Hooke discovered that the rotational speed of a single universal joint is not constant—a key characteristic that would later influence the design of improved variants. He also proposed a solution to this non-uniform velocity issue by pairing two universal joints at either end of an intermediate shaft, an arrangement that would eventually evolve into the double Cardan coupling. In 1676, Hooke coined the term “universal joint” in his book Helioscopes, and his detailed description of the mechanism in 1678 led to the widespread use of the term “Hooke's joint” in English-speaking countries.

The practical application of the Cardan coupling gained significant momentum in the 20th century, particularly with the advent of automotive and heavy machinery manufacturing. The introduction of front-wheel-drive automobiles in the 1930s, for example, relied heavily on universal joints to transmit power from the engine to the wheels while accommodating the angular misalignment between the drivetrain components. Since then, continuous advancements in materials science, manufacturing technology, and design optimization have enhanced the performance, durability, and versatility of Cardan couplings, allowing them to meet the increasingly demanding requirements of modern industrial applications, such as high-speed operation, heavy torque loads, and extreme environmental conditions.

Structural Composition and Working Principles

Basic Structure

At its core, a standard Cardan coupling consists of three main components: two yokes, a cross-shaped intermediate member (commonly referred to as a “spider” or “cross”), and bearings. Each yoke is a U-shaped component that is attached to the end of a shaft, with two forked arms that accommodate the cross member. The cross member features four trunnions (projections) that extend outward at 90-degree angles to each other, one for each arm of the two yokes. Bearings are installed between the trunnions of the cross and the arms of the yokes to facilitate smooth rotation and reduce friction between the moving parts. In some designs, a grease fitting is also included to allow for periodic lubrication of the bearings, which is essential for maintaining optimal performance and extending the service life of the coupling.

The simplicity of this design is one of the key advantages of the Cardan coupling. The yokes are typically machined from solid metal blocks or forged for enhanced strength, while the cross member is designed to withstand the torque and bending forces generated during operation. The bearings—often needle bearings due to their compact size and high load-carrying capacity—enable the yokes to rotate relative to the cross member, allowing for angular misalignment between the two shafts.

Working Principles

The primary function of a Cardan coupling is to transmit rotational motion and torque from one shaft to another when the shafts are not perfectly aligned (i.e., they intersect at an angle). The working principle of the coupling can be broken down into a series of simple mechanical interactions: when the input shaft rotates, it drives the attached yoke, which in turn imparts rotational motion to the cross member. The cross member then transfers this motion to the second yoke, which drives the output shaft. The bearings between the cross trunnions and the yoke arms allow the yokes to pivot relative to the cross member, thereby accommodating the angular misalignment between the input and output shafts.

A critical characteristic of a single Cardan coupling is its non-constant velocity (non-CV) transmission. This means that the angular velocity of the output shaft fluctuates slightly as the joint rotates, even if the input shaft rotates at a constant speed. The degree of this velocity fluctuation depends on the angle of misalignment between the two shafts: the larger the angle, the more pronounced the fluctuation. This non-uniformity occurs because the effective radius of the cross trunnions, as seen from the rotating yokes, changes throughout each revolution. For applications that require smooth, constant velocity transmission, this limitation of the single Cardan coupling has led to the development of more advanced variants, such as the double Cardan coupling.

Types of Cardan Couplings

Over time, various types of Cardan couplings have been developed to address specific application requirements, such as different levels of misalignment, torque capacity, and velocity uniformity. The most common types include the single Cardan coupling, double Cardan coupling, offset Cardan coupling, and sliding Cardan coupling. Each type has unique design features, advantages, and limitations that make it suitable for particular industrial applications.

Single Cardan Coupling

The single Cardan coupling is the simplest and most basic type of universal joint. As described earlier, it consists of two yokes, a cross member, and bearings. This type of coupling is widely used in applications where moderate angular misalignment (typically up to 30 degrees) is required, and where slight velocity fluctuations are acceptable. The single Cardan coupling is favored for its simplicity, ease of manufacturing, and cost-effectiveness. It is commonly found in automotive drivetrains (such as rear-wheel-drive vehicles), agricultural machinery, and light industrial equipment.

However, the single Cardan coupling has several limitations. In addition to its non-constant velocity transmission, it is not well-suited for high-torque applications or high-speed operation, as these conditions can lead to increased vibration, noise, and premature wear. Regular lubrication and inspection are also necessary to prevent bearing failure and ensure reliable performance.

Double Cardan Coupling

The double Cardan coupling (also known as the constant velocity or CV joint) is an improved variant of the single Cardan coupling, designed to eliminate the non-uniform velocity transmission issue. It consists of two single Cardan joints connected in series by an intermediate shaft, with the two joints oriented 90 degrees out of phase with each other. This configuration cancels out the velocity fluctuations generated by each individual joint, resulting in constant velocity transmission between the input and output shafts, even at large angles of misalignment (up to 90 degrees in some designs).

The double Cardan coupling offers several advantages over the single variant, including smoother operation, reduced vibration and noise, and higher torque-carrying capacity. These characteristics make it ideal for applications that require precise, constant velocity transmission, such as front-wheel-drive automobiles, aircraft control systems, and high-speed industrial machinery. However, the double Cardan coupling is more complex in design, more expensive to manufacture, and requires more precise assembly than the single Cardan coupling.

Offset Cardan Coupling

The offset Cardan coupling is a specialized variant that is designed to accommodate both angular misalignment and axial misalignment (i.e., parallel displacement between the shafts). This type of coupling features a modified cross member and yoke design that allows for sliding movement along the axis of the shafts, in addition to pivoting movement to accommodate angular misalignment. The offset Cardan coupling is commonly used in industrial machinery such as pumps, compressors, and conveyors, where both types of misalignment may occur due to thermal expansion, vibration, or installation errors.

One of the key advantages of the offset Cardan coupling is its ability to handle larger misalignment tolerances compared to standard single Cardan couplings. However, its more complex design requires accurate alignment during installation, and regular maintenance is necessary to ensure the sliding components remain lubricated and free from wear.

Sliding Cardan Coupling

The sliding Cardan coupling is designed for applications where the distance between the two shafts may change during operation, such as in telescopic driveshafts. This type of coupling features one yoke that slides along the other yoke or along the intermediate shaft, allowing for axial movement while still transmitting torque and accommodating angular misalignment. The sliding action compensates for changes in shaft length due to thermal expansion, vibration, or relative movement between the connected components.

Sliding Cardan couplings are commonly used in propulsion systems, agricultural machinery, and construction equipment, where the distance between the engine and the driven component may vary. Like other types of Cardan couplings, they require regular lubrication to reduce friction between the sliding components and prevent premature wear.

Material Selection for Cardan Couplings

The performance and durability of a Cardan coupling are heavily dependent on the materials used in its construction. The selection of materials is influenced by a variety of factors, including the application requirements (such as torque load, operating speed, and environmental conditions), cost considerations, and desired service life. The most commonly used materials for Cardan coupling components include steel alloys, stainless steel, aluminum alloys, and various types of bearings materials.

Steel Alloys

Heat-treated steel alloys are the most widely used materials for Cardan coupling components, particularly for yokes and cross members. These alloys typically contain elements such as chromium, nickel, and molybdenum, which enhance their strength, hardness, and resistance to wear and deformation. Heat treatment processes such as quenching and tempering further improve the mechanical properties of the steel, making it capable of withstanding high torque loads, high operating speeds, and extreme temperatures. Steel alloys are ideal for heavy-duty applications, such as construction machinery, mining equipment, and automotive drivetrains, where durability and strength are critical.

Stainless Steel

Stainless steel is used in Cardan couplings that operate in corrosive environments, such as marine applications, food processing, and chemical processing. Stainless steel contains chromium, which forms a passive oxide layer on the surface of the material, protecting it from rust and corrosion. This makes it ideal for applications where the coupling is exposed to moisture, chemicals, or other corrosive substances. Stainless steel couplings are also durable and maintain their hardness and strength in harsh environmental conditions, although they are more expensive than standard steel alloys.

Aluminum Alloys

Aluminum alloys are used in applications where weight reduction is a priority, such as aerospace and automotive applications. Aluminum is lightweight, has good thermal conductivity, and offers sufficient strength for moderate torque loads. However, aluminum alloys are not as strong or wear-resistant as steel alloys, so they are typically used in light-duty applications, such as small industrial machinery, precision equipment, and control systems. In some cases, aluminum couplings may be coated or anodized to improve their wear resistance and corrosion resistance.

Bearing Materials

The bearings in a Cardan coupling are critical for ensuring smooth rotation and reducing friction. The most common bearing materials include steel (for needle bearings and ball bearings) and bronze (for bushings). Needle bearings are particularly popular due to their compact size, high load-carrying capacity, and ability to handle both radial and axial loads. In high-temperature or high-speed applications, ceramic bearings may be used, as they offer better heat resistance and lower friction than traditional steel bearings. The selection of bearing material is based on the operating conditions of the coupling, such as temperature, speed, and load.

Key Applications of Cardan Couplings

The versatility and reliability of Cardan couplings make them suitable for a wide range of industrial applications, spanning automotive, aerospace, marine, industrial machinery, agriculture, and construction. In each of these sectors, the coupling plays a critical role in ensuring efficient power transmission between non-aligned shafts, enabling the smooth operation of complex mechanical systems.

Automotive Industry

The automotive industry is one of the largest users of Cardan couplings. In rear-wheel-drive vehicles, single Cardan couplings are used in the propeller shaft to transmit power from the transmission to the differential, accommodating the angular misalignment between these components as the vehicle moves over uneven terrain. Front-wheel-drive vehicles, on the other hand, typically use double Cardan couplings (CV joints) to transmit power from the transaxle to the front wheels, ensuring constant velocity transmission and smooth handling. Cardan couplings are also used in steering systems, drive shafts for commercial vehicles (such as trucks and buses), and off-road vehicles (such as SUVs and ATVs).

Aerospace Industry

In the aerospace industry, Cardan couplings are used in a variety of applications, including aircraft control systems, helicopter transmissions, and engine components. Aircraft control systems, for example, use small, precision Cardan couplings to transmit motion from the pilot’s controls to the flight surfaces (such as ailerons, elevators, and rudders), accommodating the angular misalignment between the control rods and the flight surface actuators. Helicopter transmissions rely on robust Cardan couplings to transmit power from the engine to the rotor system, handling high torque loads and large angles of misalignment. The aerospace industry requires Cardan couplings to be lightweight, durable, and capable of operating in extreme conditions (such as high altitude, temperature fluctuations, and vibration).

Marine Industry

The marine industry uses Cardan couplings in propulsion systems, steering systems, and auxiliary machinery. In ship propulsion systems, for example, Cardan couplings transmit power from the engine to the propeller shaft, accommodating the angular misalignment between the engine and the propeller due to the ship’s hull flexure. Stainless steel Cardan couplings are often used in marine applications to resist corrosion from saltwater. They are also used in small boats, yachts, and offshore platforms, where reliable power transmission is essential for safe operation.

Industrial Machinery

Cardan couplings are widely used in industrial machinery, including conveyors, cranes, pumps, compressors, and manufacturing equipment. Conveyor systems, for example, use Cardan couplings to transmit power from the motor to the conveyor belt, accommodating the angular misalignment between the motor and the conveyor drive shaft. Cranes use large, heavy-duty Cardan couplings to transmit power to the hoisting and traversing mechanisms, handling the high torque loads required to lift heavy objects. Pumps and compressors use offset or sliding Cardan couplings to accommodate both angular and axial misalignment, ensuring smooth operation even when the shafts are not perfectly aligned. In manufacturing equipment, such as machine tools, precision Cardan couplings are used to transmit motion between the drive system and the cutting tools, ensuring accurate and consistent performance.

Agriculture and Construction

In the agriculture and construction sectors, Cardan couplings are used in a variety of heavy machinery, such as tractors, harvesters, excavators, and bulldozers. Tractors, for example, use Cardan couplings in their power take-off (PTO) shafts to transmit power from the engine to attached implements (such as plows, mowers, and balers), accommodating the angular misalignment between the tractor and the implement. Construction machinery, such as excavators and bulldozers, use robust Cardan couplings to transmit power to the hydraulic pumps, drive wheels, and other components, handling the high torque loads and harsh operating conditions typical of construction sites. These applications require Cardan couplings to be durable, resistant to dirt and debris, and capable of withstanding frequent shock loads.

Design Optimization and Performance Enhancement

As industrial applications become increasingly demanding, the design of Cardan couplings has undergone continuous optimization to enhance performance, durability, and efficiency. Design optimization efforts focus on several key areas, including reducing stress concentrations, improving load distribution, enhancing lubrication, and minimizing vibration and noise.

One of the primary goals of design optimization is to reduce the maximum stress levels in the coupling components, particularly in the cross trunnions and yoke arms, which are subjected to high bending and shear forces during operation. Numerical simulation techniques, such as finite element analysis (FEA), are widely used to analyze the stress-strain state of Cardan coupling components and identify critical areas prone to failure. By modifying the geometric parameters of the cross member, yokes, and trunnions—such as increasing the radius of curvature at stress concentration points or optimizing the cross-sectional shape—engineers can significantly reduce stress levels and improve the load-carrying capacity of the coupling.

Improving load distribution across the bearing surfaces is another important aspect of design optimization. The load distribution between the cross trunnions and the bearings has a major impact on the service life of the coupling. Uneven load distribution can lead to premature bearing failure and reduced overall durability. By optimizing the geometric parameters of the rolling elements (such as the needles in needle bearings) and the contact surfaces between the trunnions and the bearings, engineers can ensure a more uniform load distribution, thereby extending the service life of the coupling.

Enhancing lubrication is also critical for improving the performance and durability of Cardan couplings. Proper lubrication reduces friction between the moving components, minimizes wear, and dissipates heat. Modern Cardan coupling designs incorporate advanced lubrication systems, such as sealed bearings with pre-lubrication, grease fittings with check valves to prevent contamination, and oil-lubricated systems for high-speed or high-temperature applications. In some advanced designs, the internal cross member is replaced with an external ring to improve lubricant flow and reduce friction, further enhancing performance.

Minimizing vibration and noise is another key objective of design optimization, particularly for applications that require smooth operation (such as automotive and aerospace systems). The non-uniform velocity transmission of single Cardan couplings is a major source of vibration. To address this, double Cardan couplings are used to cancel out velocity fluctuations. Additionally, optimizing the balance of the coupling components (through dynamic balancing techniques) and reducing manufacturing tolerances can minimize vibration and noise. Advanced manufacturing processes, such as precision machining and forging, ensure that the coupling components are dimensionally accurate, reducing the amount of unbalance and vibration during operation.

Maintenance and Service Life Considerations

Proper maintenance is essential for ensuring the reliable performance and extending the service life of Cardan couplings. The key maintenance requirements include regular lubrication, inspection for wear and damage, and proper alignment.

Lubrication is the most critical maintenance task for Cardan couplings. The bearings and moving components rely on lubricant to reduce friction and prevent wear. The frequency of lubrication depends on the operating conditions: couplings operating in high-speed, high-temperature, or dirty environments require more frequent lubrication than those operating in moderate conditions. It is important to use the correct type of lubricant (such as grease or oil) for the specific application, as recommended by the design specifications. Over-lubrication or under-lubrication can both lead to premature failure: over-lubrication can cause excessive heat buildup, while under-lubrication can result in metal-to-metal contact and increased wear.

Regular inspection is also necessary to identify signs of wear, damage, or misalignment. During inspection, the coupling should be checked for loose fasteners, worn bearings (indicated by noise or excessive play), damage to the yokes or cross member (such as cracks or deformation), and leakage of lubricant. Any worn or damaged components should be replaced immediately to prevent further damage to the coupling or the connected machinery. Additionally, the alignment of the shafts should be checked periodically, as improper alignment can increase stress on the coupling components and reduce service life.

Proper installation and alignment are also critical for the performance and service life of Cardan couplings. During installation, the shafts should be aligned as accurately as possible to minimize the angle of misalignment. The use of alignment tools (such as laser alignment systems) can help ensure precise alignment. Additionally, the yokes should be properly secured to the shafts using the correct fasteners and torque specifications. Improper installation can lead to excessive vibration, premature wear, and even catastrophic failure of the coupling.

Conclusion

The Cardan coupling is a versatile and indispensable component in the field of mechanical power transmission. From its historical origins in the work of early scholars to its modern-day applications in automotive, aerospace, marine, and industrial systems, the Cardan coupling has evolved continuously to meet the changing demands of technology and industry. Its simple yet effective design—consisting of yokes, a cross member, and bearings—enables it to transmit torque and rotational motion between non-aligned shafts, making it a critical component in countless mechanical systems.

The various types of Cardan couplings—including single, double, offset, and sliding variants—offer unique advantages that make them suitable for specific applications. Material selection plays a key role in determining the performance and durability of the coupling, with steel alloys, stainless steel, and aluminum alloys being the most commonly used materials. Design optimization efforts, driven by advanced numerical simulation techniques, have further enhanced the performance of Cardan couplings, enabling them to handle higher torque loads, higher speeds, and larger angles of misalignment.

Proper maintenance, including regular lubrication, inspection, and alignment, is essential for ensuring the reliable operation and extending the service life of Cardan couplings. As industrial applications continue to evolve, the Cardan coupling will undoubtedly remain a cornerstone of power transmission technology, with ongoing advancements in design, materials, and manufacturing further expanding its capabilities and applications.

« Cardan Couplings » Post Date: 2023/7/3

URL: http://www.rokee.com/en/tags/CardanCouplings.html