Cardan Driveshafts

Rokee is Cardan Driveshafts Manufacturer, Customizable according to the cardan driveshafts drawings provided by the customer, Support Export.

The Cardan Driveshafts used in important equipment and core industrial fields have not only undergone careful design, but also comprehensive torque, stiffness, balance performance and life tests.

All standard products of Rokee are optimized design products based on the combination of decades of experience and computer design technology.,The Cardan Driveshafts we are proud of are not only different from the national technical standards of China but also the standards of other manufacturers in the world. Unique design ideas and make perfection more perfect sprit drive our products find a better balance between lower price and rotational and transmission torque performance.

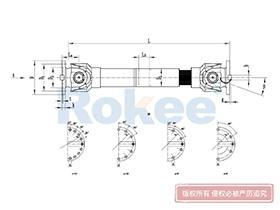

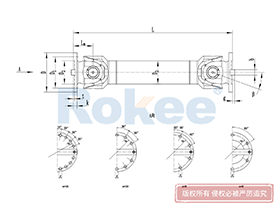

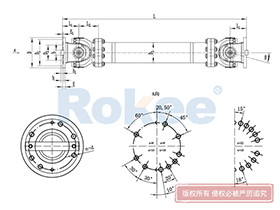

SWC-BH Universal Coupling

standard telescopic welded

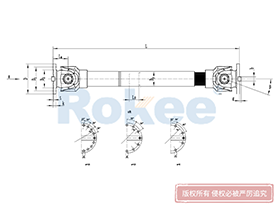

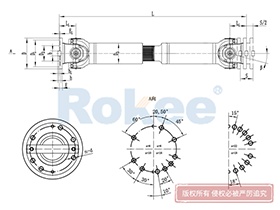

View MoreSWC-CH Uuniversal Coupling

Long Telescopic Welded

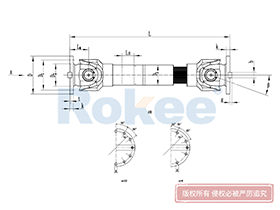

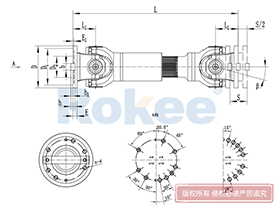

View MoreSWC-DH Universal Coupling

Short Telescopic Welded

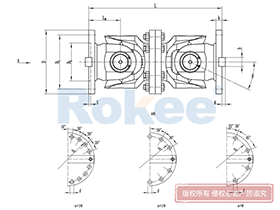

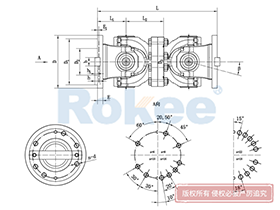

View MoreSWC-WD Universal Coupling

Non-telescopic Short

View MoreSWC-WH Universal Coupling

Non-telescopic Welded

View MoreSWP-A Universal Coupling

Long Type, Telescopic

View MoreSWP-B Universal Coupling

Short Type, Telescopic

View MoreSWP-C Universal Coupling

Short Type, Non-telescopic

View MoreSWP-D Universal Coupling

Long Type, Non-elescopic

View More

In the realm of mechanical power transmission, few components have proven as versatile and indispensable as the cardan driveshaft. Serving as a critical link between non-coaxial shafts, this mechanical assembly enables the seamless transfer of rotational motion and torque even when significant angular misalignment exists between the driving and driven components. From the powertrains of commercial vehicles to the heavy machinery in industrial plants and the propulsion systems of marine vessels, the cardan driveshaft underpins the operation of countless mechanical systems that drive modern society.

To appreciate the significance of the cardan driveshaft, it is first necessary to grasp its core definition and historical context. The term "cardan" derives from the 16th-century Italian mathematician and physicist Girolamo Cardano, who formalized the mathematical principles governing the universal joint—a key component of the cardan driveshaft. While the basic concept of flexible power transmission dates back further, Cardano’s work laid the theoretical foundation for the modern design. A cardan driveshaft, at its essence, is a mechanical assembly designed to transmit rotational power between two shafts that are not aligned along the same axis. Unlike rigid driveshafts, which require precise coaxial alignment to function effectively, the cardan driveshaft incorporates universal joints (also known as U-joints) that allow for angular displacement, making it uniquely suited for applications where shafts move relative to each other during operation.

Fundamental Structure and Working Principles

The functionality of the cardan driveshaft stems from its elegant yet robust structural design. The core components of a typical cardan driveshaft include universal joints, yokes, a central shaft, and often splined connections for length compensation. Each of these components works in tandem to ensure efficient power transmission while accommodating misalignment.

Universal joints are the heart of the cardan driveshaft. A basic universal joint consists of two yokes—fork-shaped components attached to the ends of the driving and driven shafts—and a cross-shaped intermediate member called a spider. The spider features four trunnions (cylindrical projections) that fit into bearings within the forks of the yokes. This configuration allows the yokes to rotate relative to each other around the spider, enabling angular misalignment between the connected shafts. When the driving shaft rotates, it imparts motion to its associated yoke, which in turn rotates the spider. The spider then transfers this rotational motion to the opposite yoke, driving the driven shaft. This transfer of motion occurs smoothly even as the angle between the shafts changes during operation, a capability that distinguishes the cardan driveshaft from rigid alternatives.

While a single universal joint can accommodate angular misalignment, it has a notable limitation: it introduces velocity fluctuations. As the angle between the shafts increases, the output speed of the driven shaft varies cyclically relative to the input speed of the driving shaft. This phenomenon, known as angular velocity variation, can cause vibration and noise, which are undesirable in many applications. To mitigate this issue, most cardan driveshafts employ a double universal joint configuration (also called a double cardan driveshaft). In this design, two universal joints are mounted at either end of the central shaft, with the yokes aligned such that the velocity fluctuations from the first joint are canceled out by the second. This arrangement ensures constant output velocity, even at larger angular misalignments, making the double cardan driveshaft suitable for high-precision and high-speed applications.

Another critical component of the cardan driveshaft is the splined connection, which allows for axial length compensation. In many mechanical systems, the distance between the driving and driven shafts can change during operation—for example, due to suspension movement in vehicles or thermal expansion in industrial machinery. The splined connection consists of a male spline (on one shaft segment) and a female spline (on another), allowing the segments to slide relative to each other while maintaining rotational engagement. This feature ensures that the cardan driveshaft can adapt to axial movements without compromising power transmission or structural integrity.

Material Selection and Manufacturing Processes

The performance and durability of a cardan driveshaft are heavily influenced by the materials used in its construction and the manufacturing processes employed. Given the demanding operating conditions—including high torque, cyclic loading, vibration, and exposure to harsh environments—materials must strike a balance between strength, rigidity, durability, and weight efficiency. The selection of materials is typically tailored to the specific application, with considerations for torque requirements, operating speed, environmental conditions, and weight constraints.

Steel alloys are the most common materials for cardan driveshaft components, particularly for the central shaft and yokes. Carbon steel and alloy steels (such as chromium-molybdenum steel) are preferred for their excellent strength-to-weight ratio, high torque-bearing capacity, and resistance to wear and fatigue. These steels undergo heat treatment processes—such as quenching and tempering—to enhance their mechanical properties, ensuring they can withstand the torsional and shear stresses inherent in power transmission. For applications requiring higher corrosion resistance, stainless steel may be used, especially in marine or industrial environments where exposure to moisture, chemicals, or saltwater is prevalent.

In recent years, lightweight materials have gained traction in cardan driveshaft design, driven by the growing demand for fuel efficiency in automotive and aerospace applications. Aluminum alloys (such as 6061 and 7075) are increasingly used for shafts in light-duty vehicles, as they offer a 30-40% weight reduction compared to steel while maintaining sufficient strength for moderate torque requirements. However, aluminum’s lower torque capacity limits its use to light and medium-duty applications. Carbon fiber-reinforced polymers (CFRPs) represent the cutting edge of lightweight material technology for cardan driveshafts. These composites offer exceptional strength-to-weight ratios, with weight reductions of up to 60% compared to steel, while providing high stiffness and resistance to fatigue. CFRP driveshafts are particularly well-suited for high-performance vehicles and aerospace applications, where weight savings directly translate to improved efficiency and performance.

The manufacturing of cardan driveshafts involves a series of precision processes to ensure dimensional accuracy and structural integrity. The central shaft is typically produced using tube drawing or seamless rolling processes for steel and aluminum, while CFRP shafts are manufactured using filament winding or prepreg molding techniques. Yokes and spiders are often forged from steel billets to achieve high strength and uniform grain structure, followed by machining processes (such as milling, turning, and drilling) to achieve precise dimensions. The universal joint bearings are usually press-fitted into the yoke forks, and the entire assembly undergoes rigorous quality control checks—including dimensional inspection, torque testing, and fatigue testing—to ensure compliance with performance requirements. Advanced manufacturing technologies, such as computer numerical control (CNC) machining and finite element analysis (FEA) simulation, have revolutionized the design and production of cardan driveshafts, enabling engineers to optimize designs for specific applications and reduce development time.

Diverse Applications Across Industries

The unique capabilities of the cardan driveshaft—its ability to accommodate angular misalignment and axial movement while transmitting high torque—make it indispensable across a wide range of industries. From automotive and industrial machinery to agriculture, marine, and aerospace, the cardan driveshaft plays a critical role in powering essential equipment and systems.

The automotive industry is one of the largest consumers of cardan driveshafts. In rear-wheel-drive (RWD) and four-wheel-drive (4WD) vehicles, cardan driveshafts transmit power from the transmission to the differential, which then distributes power to the wheels. In commercial vehicles, such as trucks and buses, heavy-duty cardan driveshafts are used to handle the high torque requirements of diesel engines, ensuring reliable power transmission even under full load. Off-road vehicles, including SUVs, tractors, and construction equipment, rely on cardan driveshafts to navigate uneven terrain, as the flexible design accommodates the constant changes in shaft alignment caused by suspension movement. Even in some front-wheel-drive (FWD) vehicles, compact cardan driveshafts are used to transmit power from the transaxle to the front wheels, particularly in vehicles with independent suspension systems.

The industrial machinery sector is another major application area for cardan driveshafts. In steel mills, cardan driveshafts power rolling mills, which require high torque transmission and the ability to accommodate misalignment between the motor and the rolling stands. Paper mills use cardan driveshafts in high-speed printing and papermaking machinery, where smooth power transmission is essential to maintain product quality. Mining equipment, such as excavators, loaders, and crushers, relies on heavy-duty cardan driveshafts to operate in harsh, dusty environments, transmitting power between components that are often subject to significant misalignment. Other industrial applications include conveyors, mixers, and pumps, where cardan driveshafts ensure reliable operation even in dynamic conditions.

Agricultural machinery extensively uses cardan driveshafts to connect tractors to various implements, such as mowers, balers, seeders, and harvesters. These applications require the driveshaft to accommodate the varying angles between the tractor and the implement as the equipment moves over uneven farmland. The synergy between cardan driveshafts and power take-off (PTO) systems is particularly important in agriculture, as PTO systems transfer power from the tractor’s engine to the implement via the cardan driveshaft, enabling efficient operation of agricultural equipment.

Marine and aerospace applications also benefit from the versatility of cardan driveshafts. In marine vessels, cardan driveshafts transmit power from the engine to the propeller, accommodating the movement of the ship’s hull and the misalignment between the engine and the propeller shaft. This ensures efficient power transmission even in rough seas, where the relative position of components can change dynamically. In the aerospace industry, cardan driveshafts are used in aircraft control systems and helicopter transmissions, where precision and reliability are paramount. The lightweight properties of advanced materials, such as CFRPs, make cardan driveshafts ideal for aerospace applications, where weight savings are critical for fuel efficiency and payload capacity.

Operational Challenges and Maintenance Considerations

Despite their robust design and versatility, cardan driveshafts face several operational challenges that can impact performance and service life. Understanding these challenges and implementing proper maintenance practices are essential to ensure reliable operation and minimize downtime.

One of the primary challenges is velocity fluctuation, as mentioned earlier. Single universal joint configurations introduce cyclic variations in output speed, which can cause vibration, noise, and increased wear on connected components. This issue is exacerbated at larger angular misalignments, making single universal joint driveshafts unsuitable for high-speed or high-precision applications. The solution, as noted, is the use of double universal joint configurations, which cancel out velocity fluctuations, but this adds complexity and cost to the assembly.

Another significant challenge is wear and tear on universal joint components. The spider trunnions and bearings are subject to constant friction and cyclic loading during operation, which can lead to wear over time. Lack of proper lubrication accelerates this wear, resulting in increased play in the universal joint, which causes vibration and can eventually lead to component failure. Corrosion is also a major concern, particularly in harsh environments such as marine, mining, and agricultural applications, where exposure to moisture, salt, and chemicals can degrade metal components.

Proper maintenance is critical to addressing these challenges and extending the service life of cardan driveshafts. Regular lubrication of universal joints and splined connections is essential to reduce friction and prevent wear. The type of lubricant should be selected based on the operating environment—for example, high-temperature lubricants for industrial applications and corrosion-resistant lubricants for marine environments. Regular inspection of the driveshaft assembly, including checking for excessive play in universal joints, damage to the central shaft, and wear on splined connections, can help identify potential issues before they lead to failure. In addition, proper alignment of the driving and driven shafts—even though the cardan driveshaft can accommodate misalignment—reduces stress on the universal joints and extends service life. For applications with high cyclic loading, periodic fatigue testing may be necessary to ensure the driveshaft remains structurally sound.

Environmental factors also pose challenges to cardan driveshaft operation. Extreme temperatures can affect the performance of lubricants and materials, with high temperatures causing lubricant degradation and low temperatures increasing material brittleness. Dust, dirt, and debris can enter universal joints and splined connections, causing abrasion and wear. To mitigate these issues, protective covers and seals are often used to shield critical components from environmental contaminants. In marine applications, specialized corrosion-resistant materials and coatings are employed to protect against saltwater corrosion.

Future Trends and Technological Advancements

The cardan driveshaft industry is poised for significant evolution, driven by advancements in materials science, manufacturing technology, and the growing demand for more efficient and sustainable mechanical systems. Several key trends are shaping the future of cardan driveshaft design and application.

The continued shift toward lightweight materials is one of the most prominent trends. As industries such as automotive and aerospace strive to reduce carbon emissions and improve fuel efficiency, the demand for lightweight cardan driveshafts made from aluminum alloys and CFRPs is expected to grow. CFRP driveshafts, in particular, are gaining traction in high-performance vehicles and electric vehicles (EVs). Electric vehicles, which have high torque outputs and require lightweight components to maximize battery range, benefit significantly from CFRP driveshafts, which offer both weight savings and high torque-bearing capacity. The global market for composite cardan driveshafts is projected to grow at a compound annual growth rate (CAGR) of over 5% in the coming decade, driven by these factors.

The integration of smart technology into cardan driveshafts represents another exciting trend. The incorporation of sensors—such as strain gauges, accelerometers, and temperature sensors—into the driveshaft assembly allows for real-time monitoring of operating conditions, including torque load, vibration, temperature, and wear. This data can be transmitted to a central control system, enabling predictive maintenance. Predictive maintenance algorithms use this data to identify potential issues before they lead to failure, reducing downtime and maintenance costs. Smart cardan driveshafts are particularly valuable in industrial and automotive applications, where unplanned downtime can result in significant financial losses.

Advancements in manufacturing technology are also driving innovation in cardan driveshaft design. Additive manufacturing (3D printing) offers new possibilities for creating complex components, such as yokes and spiders, with optimized geometries that reduce weight while maintaining strength. 3D printing also enables the production of custom driveshafts for specialized applications, reducing lead times and production costs. FEA simulation tools continue to evolve, allowing engineers to model and optimize driveshaft designs for specific operating conditions, ensuring maximum efficiency and durability. The use of automation in manufacturing processes, such as robotic assembly and CNC machining, is also improving production efficiency and quality control.

The expansion of cardan driveshaft applications into new sectors is another emerging trend. The renewable energy industry, for example, is increasingly using cardan driveshafts in wind turbines and solar tracking systems. In wind turbines, cardan driveshafts transmit power from the rotor to the generator, accommodating the misalignment caused by wind-induced movement. Solar tracking systems use cardan driveshafts to adjust the position of solar panels, ensuring maximum exposure to sunlight. The growing demand for renewable energy is expected to drive significant growth in the use of cardan driveshafts in these applications.

Conclusion

The cardan driveshaft is a testament to the ingenuity of mechanical engineering, offering a simple yet effective solution to the complex problem of power transmission between non-coaxial shafts. From its humble origins rooted in mathematical principles to its current status as a critical component in diverse industries, the cardan driveshaft has evolved significantly, driven by advancements in materials, manufacturing, and design. Its ability to accommodate angular misalignment and axial movement while transmitting high torque makes it indispensable in automotive, industrial, agricultural, marine, and aerospace applications.

While operational challenges such as velocity fluctuation, wear, and corrosion persist, proper maintenance practices and technological innovations—such as double universal joint configurations and protective coatings—have mitigated these issues. Looking to the future, the cardan driveshaft industry is poised for continued growth and innovation, with lightweight materials, smart technology, and advanced manufacturing processes leading the way. As industries strive for greater efficiency, sustainability, and reliability, the cardan driveshaft will remain a key enabler, adapting to new applications and challenges to power the mechanical systems of tomorrow.

In essence, the cardan driveshaft is more than just a mechanical component; it is a vital link in the chain of power transmission that underpins modern society. Its versatility, reliability, and ongoing evolution ensure that it will continue to play a critical role in shaping the future of engineering and industry.

« Cardan Driveshafts » Post Date: 2023/7/3

URL: http://www.rokee.com/en/tags/CardanDriveshafts.html